Method for covering preformed soldering lug on chip sealing cover plate

A preformed solder piece and sealing cover technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of welding influence, performance and shape change, and low production efficiency between the sealing cover and the lower shell. Achieve the effect of high reliability, convenient processing and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate the understanding of those skilled in the art, the composition principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

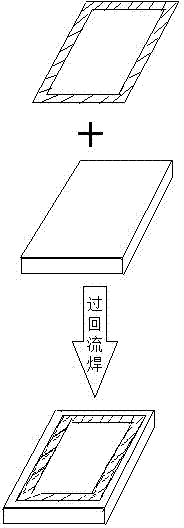

[0017] The method of the present invention utilizes the feature that the melting point of the AuSn alloy preform is higher than that of pure tin, and the AuSn alloy preform is firmly covered on the sealing cover plate by adding tin and performing reflow soldering at an appropriate temperature. AuSn alloy solder preforms generally refer to alloy materials with weight percentages of Au80% and Sn20%, and are preformed into solder tabs. Generally, the place where the sealing cover is in contact with the shell is only its periphery. Therefore, the solder preform of AuSn alloy is generally made into a hollow soldering piece corresponding to the peripheral shape of the sealing cover.

[0018] Such as figure 1 , the specific steps of the method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com