Preparation method of titanium oxide nanoflower film

A titanium dioxide and nanoflower technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of high pollution, heavy metal ion environmental pollution, difficulty in large-scale production, etc., and achieve strong photocatalytic activity and preparation method. Simple, novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 1mL of tetrabutyl titanate, 15mL of concentrated hydrochloric acid, and 15mL of deionized water into a 50mL reaction kettle with a polytetrafluoroethylene liner and mix evenly, then place the cleaned FTO conductive glass with a size of 1.5×3.5cm on an incline In the reaction solution, the reaction vessel was sealed and placed at 180° C. for 1 hour to react. After the reaction is finished, the product is washed and dried to prepare a titanium dioxide nanoflower film.

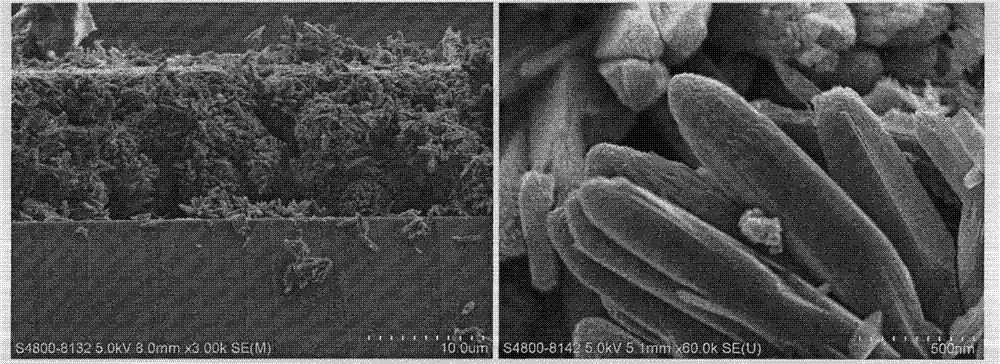

[0025] figure 1 It is a field emission scanning electron microscope image of the titanium dioxide nanoflower film prepared in Example 1 of the present invention. It can be seen from the cross-sectional view that the thickness of the film is about 15 μm, and the film is constructed of clusters of titanium dioxide nanoflowers. Each nanoflower is composed of petals with a length of about 1.5 μm and a width of about 450 nm.

Embodiment 2

[0027] Add 1mL of tetrabutyl titanate, 15mL of concentrated hydrochloric acid, and 15mL of deionized water into a 50mL reaction kettle with a polytetrafluoroethylene liner and mix evenly, then place the cleaned FTO conductive glass with a size of 1.5×3.5cm on an incline In the reaction solution, the reaction vessel was sealed and placed at 180° C. for 4 hours. After the reaction is finished, the product is washed and dried to prepare a titanium dioxide nanoflower film.

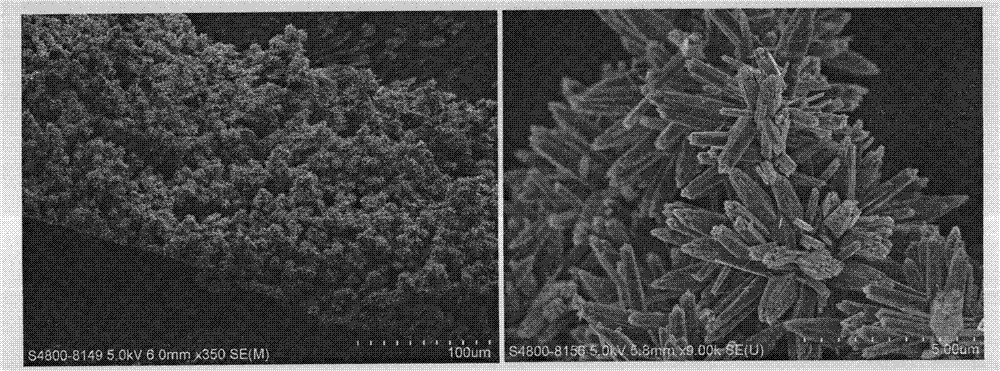

[0028] figure 2 It is a field emission scanning electron microscope image of the titanium dioxide nanoflower film prepared in Example 2 of the present invention. It can be seen from the cross-sectional view that the thickness of the film is about 160 μm, and the film is constructed of clusters of titanium dioxide nanoflowers. Each nanoflower is composed of petals with a length of about 1.9 μm and a width of about 400 nm.

Embodiment 3

[0030] Add 1mL of tetrabutyl titanate, 15mL of concentrated hydrochloric acid, and 15mL of deionized water into a 50mL reaction kettle with a polytetrafluoroethylene liner and mix evenly, then place the cleaned FTO conductive glass with a size of 1.5×3.5cm on an incline In the reaction solution, the reaction vessel was sealed and placed at 180° C. for 24 hours. After the reaction is finished, the product is washed and dried to prepare a titanium dioxide nanoflower film.

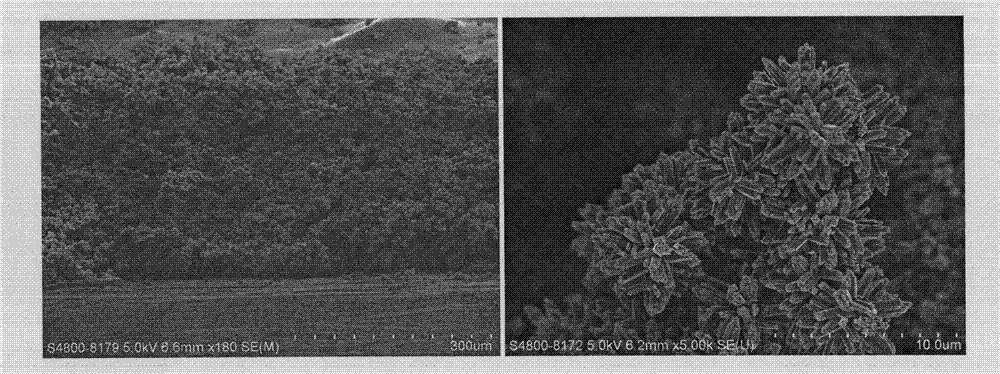

[0031] image 3 It is the field emission scanning electron microscope image of the titanium dioxide nanoflower film prepared in Example 3 of the present invention. It can be seen from the cross-sectional view that the thickness of the film is about 300 μm, and the film is constructed of clusters of titanium dioxide nanoflowers. Each nanoflower is composed of petals with a length of about 1.3 μm and a width of about 380 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com