Deep dehydration device and dehydration method for sludge

A deep dehydration and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of large equipment damage, difficulty in accurately grasping shaft balance, and difficult maintenance, so as to reduce pollution and reduce the moisture content of sludge , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

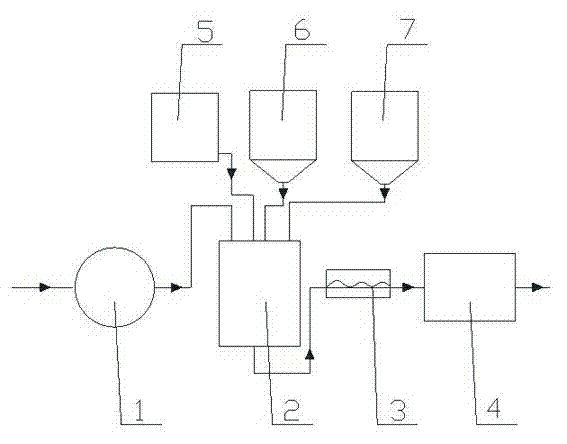

[0029] Embodiment 1: as figure 1 and figure 2 As shown, a deep sludge dehydration device includes a thickening tank 1, a conditioning tank 2, and a membrane filter press 4. The thickening tank 1 is provided with a sludge inlet and an outlet, and the outlet of the thickening tank 1 and the inlet of the conditioning tank 2 pass through The pipes are connected, and the outlet of the conditioning tank 2 is connected to the diaphragm filter press 4 through the feed pump 3; a dosing device is provided above the conditioning tank 2, and the dosing device includes a first dosing device 5 and a second dosing device 6 And the third dosing device 7, wherein the first dosing device 5 is a PAM dosing device; the second dosing device 6 is a dosing device that calcium chloride, magnesium chloride and polyaluminum chloride mixture are housed; the third dosing device Device 7 is a calcium oxide dosing device.

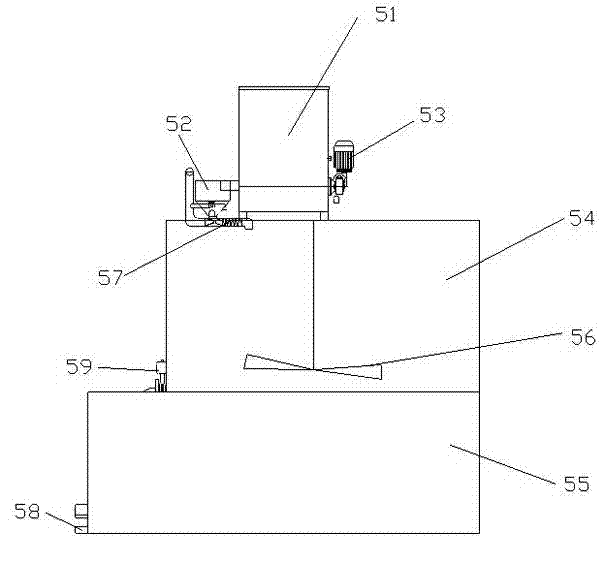

[0030]The above-mentioned first dosing device 5 includes a medicine bin 51 , a h...

Embodiment 2

[0038] Embodiment 2: basically the same as Example 1, the difference is the addition of each medicament, specifically: the addition of PAM is 3% of the absolute dry sludge weight, polymerized AlCl 3 The addition amount is 2% of the dry sludge weight, CaCl 2 The amount of addition is 0.1% of the weight of absolute dry sludge, MgCl 2 The addition amount of CaO is 0.2% of the weight of the absolute dry sludge, and the amount of CaO is 0.2‰ of the weight of the absolute dry sludge. According to the method of this embodiment, the moisture content of the mud cake obtained after press filtration for 60 minutes was 55%.

Embodiment 3

[0039] Embodiment 3: basically the same as Example 1, the difference is the addition of each medicament, specifically: the addition of PAM is 6% of the absolute dry sludge weight, polymerized AlCl 3 The addition amount is 5% of the dry sludge weight, CaCl 2 The amount of addition is 0.5% of the weight of absolute dry sludge, MgCl 2 The addition amount of CaO is 0.5% of the weight of the absolute dry sludge, and the amount of CaO is 0.5‰ of the weight of the absolute dry sludge. According to the method of this example, the water content of the mud cake obtained after press filtration for 60 minutes was 57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com