Multiferroic ceramics with room-temperature highly ferromagnetic-ferroelectric and highly-magnetic dielectric effects and preparation method of multiferroic ceramics

A technology of multiferroic ceramics and dielectric effect, applied in the field of multiferroic ceramics and its preparation, can solve the problems of weak ferroelectricity and ferromagnetism, low magnetodielectric effect, etc., and achieve good ferromagnetism and ferroelectricity , good comprehensive performance and huge economic application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

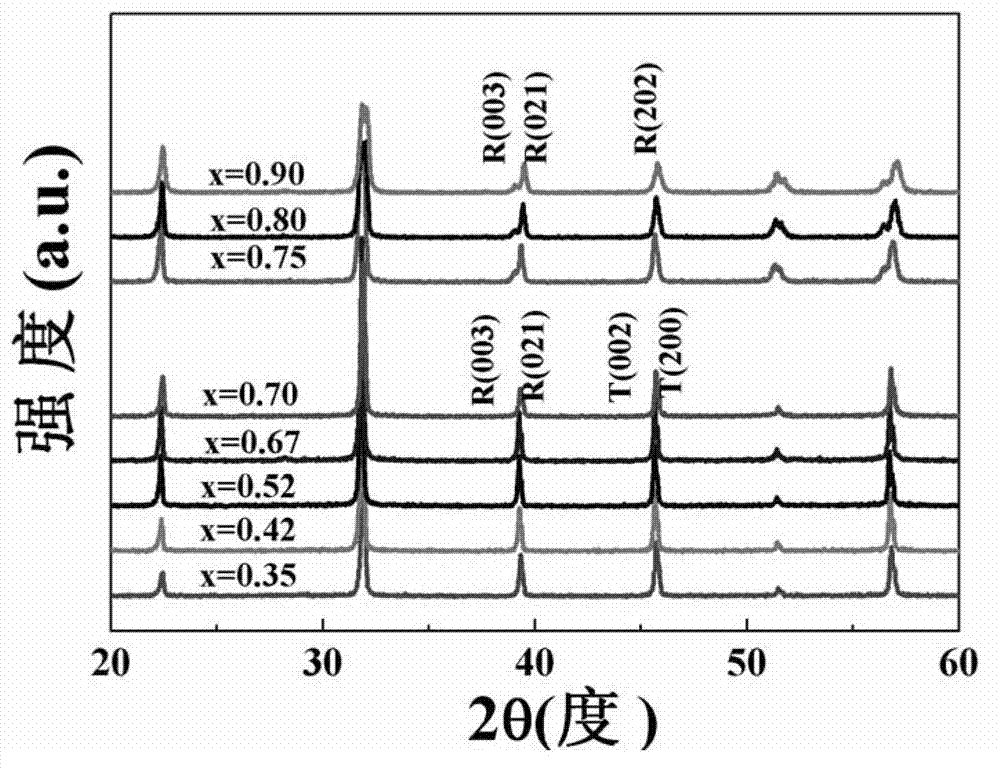

[0019] Specific embodiment 1: The chemical formula of the multiferroic ceramics with high ferromagnetism-ferroelectricity and high magnetodielectric effect in this embodiment is (1-x)Ba 0.70 Ca 0.30 TiO 3 -xBiFeO 3 , where x is the mole fraction, 0.52≤x≤0.70.

specific Embodiment approach 2

[0020] Specific embodiment two: the preparation method of the multiferroic ceramics of room temperature high ferromagnetism-ferroelectricity and high magnetodielectric effect of this embodiment, carries out according to the following steps:

[0021] 1. The raw material BaCO 3 , CaCO 3 、TiO 2 、 Bi 2 o 3 and Fe 2 o 3 Press (1-x)Ba 0.70 Ca 0.30 TiO 3 -xBiFeO 3 Stoichiometric ratio weighing of chemical formula, where 0.52≤x≤0.70;

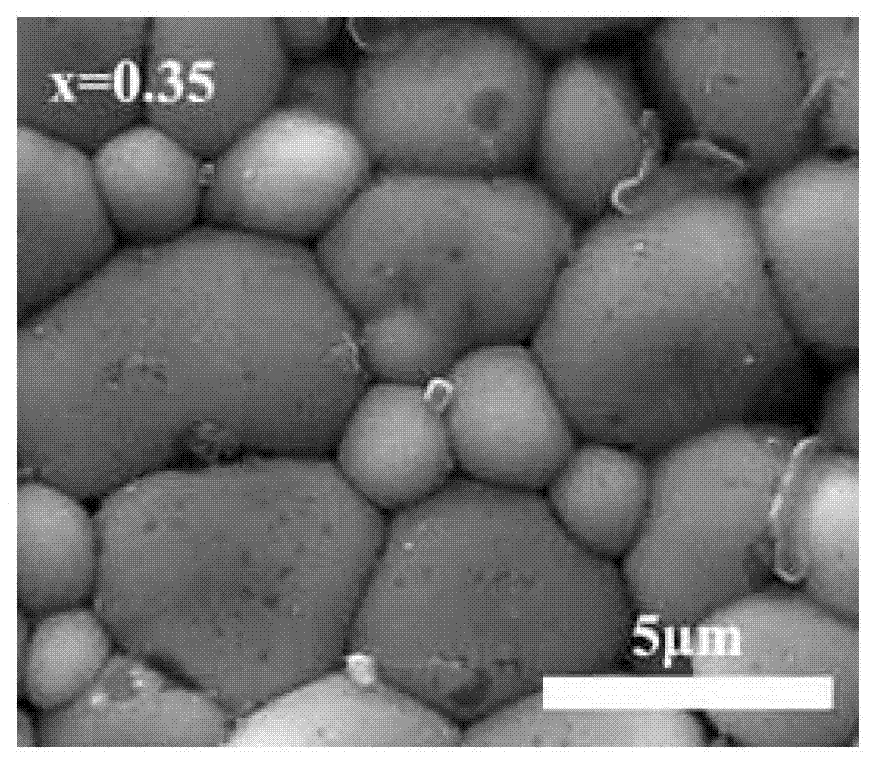

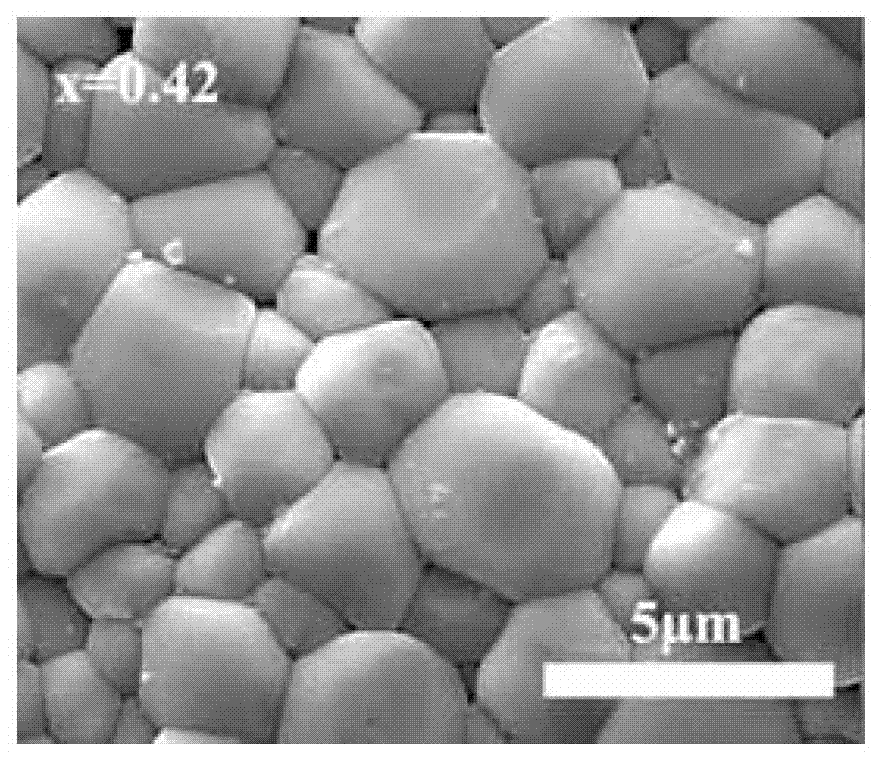

[0022] 2. Mix the raw materials weighed in step 1, use absolute ethanol as the medium, and wet ball mill for 24-26 hours at a speed of 125-140 rpm, then dry at 50°C, and keep the pressure at 10-15MPa 1min~2min, the obtained diameter is 30~35mm, the thickness is 3~5mm to wait for calcined pressed tablet; Wherein the ratio of the quality of absolute ethanol and raw material total mass is (1.3~1.5): 1; The used grinding ball of ball mill is made of Agate balls with a diameter of 20mm, a diameter of 10mm and a diameter of 6mm are composed of agat...

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 2 in that: in step 1, x=0.67. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com