Acrylic ester composition, preparation method of acrylic ester composition, and adhesive tape applying composition

A technology of acrylate and composition, applied in the field of acrylate composition and its preparation and adhesive tape applied with the composition, can solve the problem of inability to use professional equipment synchronously in factory inspection, lack of in-depth knowledge of adhesives, and neglect of adhesives. Cohesive strength performance and other issues, to achieve good initial adhesion performance, good shear resistance, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is described in further detail below by way of examples.

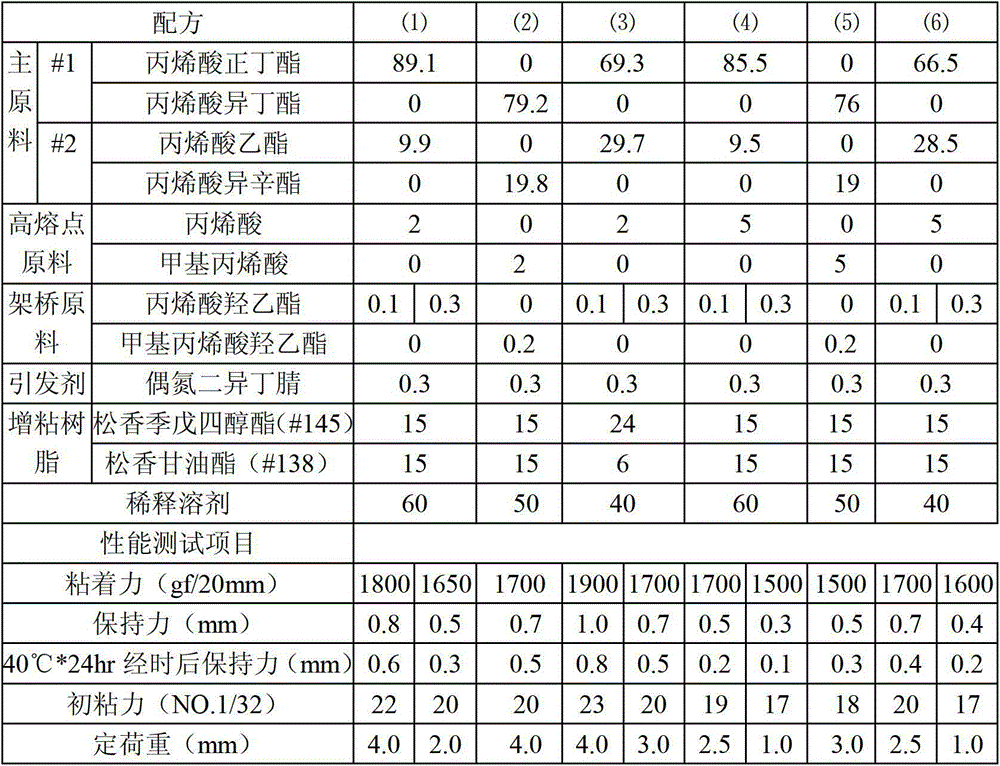

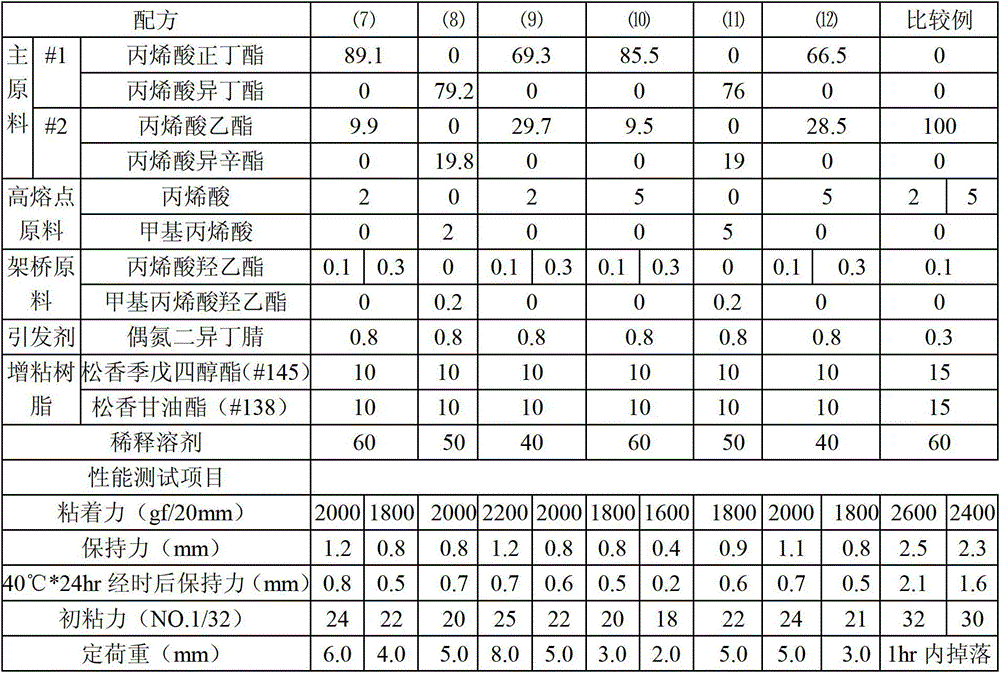

[0030] As shown in Table 1 and Table 2, the present invention includes 12 examples and 2 comparative examples, wherein due to the different amounts of bridging raw materials, each example includes two implementation sub-examples.

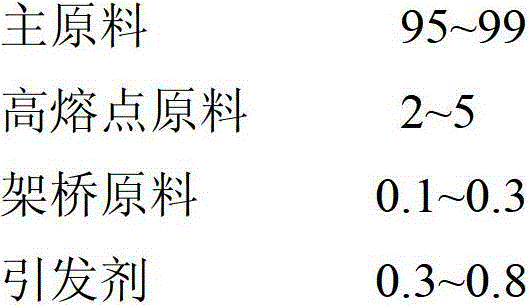

[0031] Mix the main raw material, high melting point raw material, bridging raw material, initiator, and 30% dilution solvent as shown in Table 1, stir evenly, heat to 75-85°C, cool down to 35-45°C after fully reacting, add the remaining 70% dilute solvent and tackifying resin to obtain an acrylate composition, and then mix and stir the acrylate composition and curing agent for 20 minutes to obtain an acrylate adhesive. The dilution solvent is mixed with any two of ethyl acetate, toluene, and methyl ethyl ketone, and the mixing ratio of high boiling point solvent and low boiling point solvent is 1:3~5.

[0032] Then the prepared acrylate adhesive is coated on the highly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com