Biomimetic mechanical active hydrogel adhesive and preparation method thereof

A biomimetic machine, active water technology, used in pharmaceutical formulations, bandages, drug delivery, etc., can solve the problems of lack of skin tissue adhesion properties, complex preparation process, strong cytotoxicity, etc., to increase structural stability and mechanical properties, Simple synthesis method and the effect of improving tissue adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the present embodiment mechanically active hydrogel adhesive comprises the following steps:

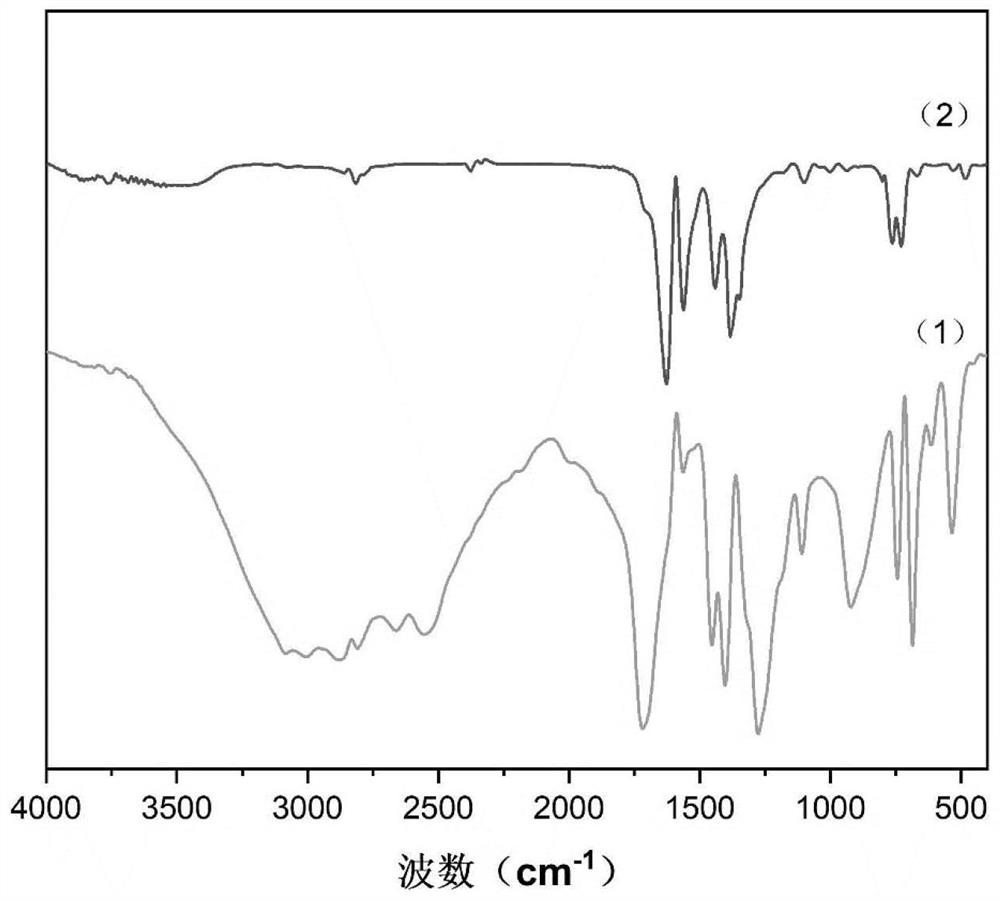

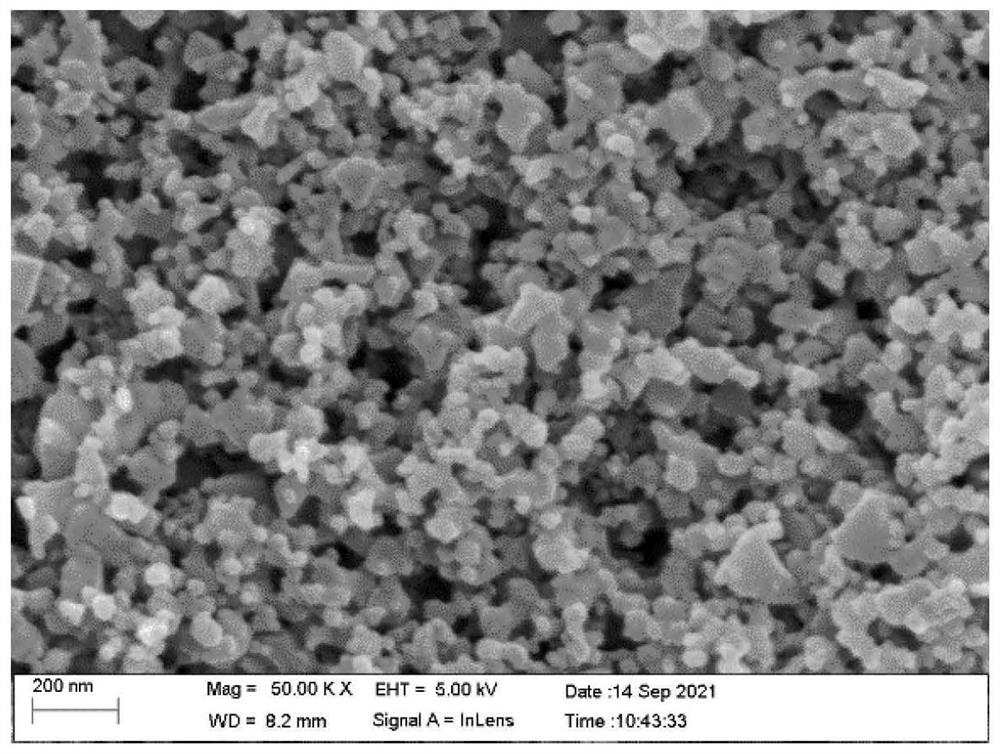

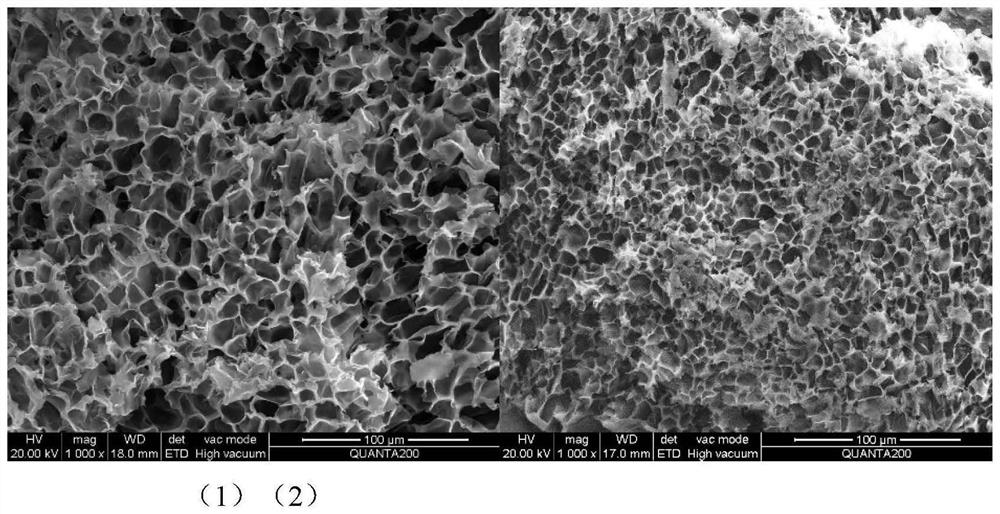

[0039] 1) Dissolve 0.3g of copper acetate monohydrate in 4ml of deionized water, and dissolve 0.22g of 1,3,5-benzenetricarboxylic acid in 4ml of absolute ethanol. Add the copper acetate monohydrate solution dropwise to the 1,3,5-benzenetricarboxylic acid solution, then stir at room temperature at a speed of 300r / min for about 30min to obtain a dark turquoise suspension, and at a speed of 5000r / min The suspension was centrifuged for 8 min to separate HKUST-1 nanoparticles. The product was washed with 50% ethanol solution, and the washing was repeated three times to remove residual reactants. The collected samples were dried under vacuum and sealed and stored in a desiccator. figure 1 (1) is 1,3,5-benzenetricarboxylic acid and (2) is the FTIR spectrum of HKUST-1 nanoparticles, 1619cm -1 、1566cm -1 、1440cm -1 、1370cm -1 The asymmetric and symmetric vi...

Embodiment 2

[0044] The preparation method of the present embodiment mechanically active hydrogel adhesive comprises the following steps:

[0045] 1) Dissolve 0.3g of copper acetate monohydrate in 4ml of deionized water, and dissolve 0.22g of 1,3,5-benzenetricarboxylic acid in 4ml of absolute ethanol. Add the copper acetate monohydrate solution dropwise to the 1,3,5-benzenetricarboxylic acid solution, then stir at room temperature at a speed of 300r / min for about 30min to obtain a dark turquoise suspension, and at a speed of 5000r / min The suspension was centrifuged for 8 min to separate HKUST-1 nanoparticles. The product was washed with 50% ethanol solution, and the washing was repeated three times to remove residual reactants. The collected samples were dried under vacuum and sealed and stored in a desiccator.

[0046] 2) In a 50ml flask equipped with a magnetic stirring bar, dissolve 1.8g of N-isopropylacrylamide, 0.0036g of N,N-methylenebisacrylamide and 0.15g of sodium alginate at 25°C...

Embodiment 3

[0050] The preparation method of the present embodiment mechanically active hydrogel adhesive comprises the following steps:

[0051] 1) Dissolve 0.3g of copper acetate monohydrate in 4ml of deionized water, and dissolve 0.22g of 1,3,5-benzenetricarboxylic acid in 4ml of absolute ethanol. Add the copper acetate monohydrate solution dropwise to the 1,3,5-benzenetricarboxylic acid solution, then stir at room temperature at a speed of 300r / min for about 30min to obtain a dark turquoise suspension, and at a speed of 5000r / min The suspension was centrifuged for 8 min to separate HKUST-1 nanoparticles. The product was washed with 50% ethanol solution, and the washing was repeated three times to remove residual reactants. The collected samples were dried under vacuum and sealed and stored in a desiccator.

[0052] 2) In a 50ml flask equipped with a magnetic stirring bar, dissolve 1.8g of N-isopropylacrylamide, 0.0036g of N,N-methylenebisacrylamide and 0.15g of sodium alginate at 25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com