Conductive coating composition

A technology of conductive coatings and compositions, applied in conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve problems such as high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

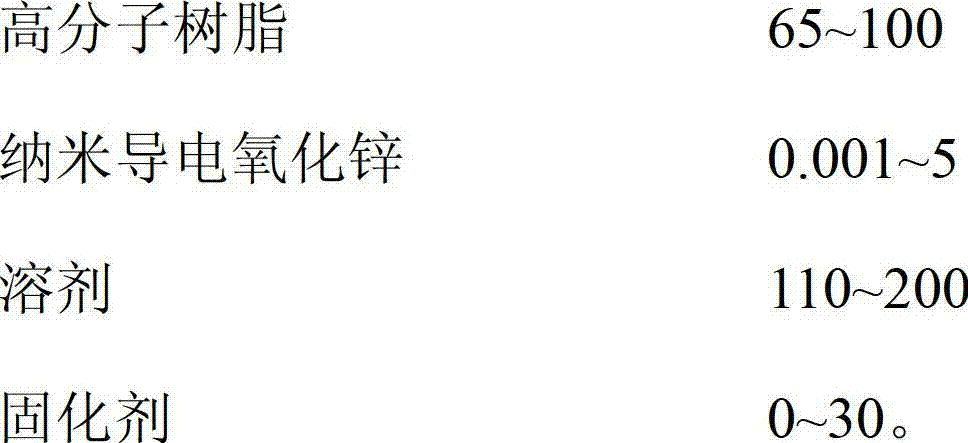

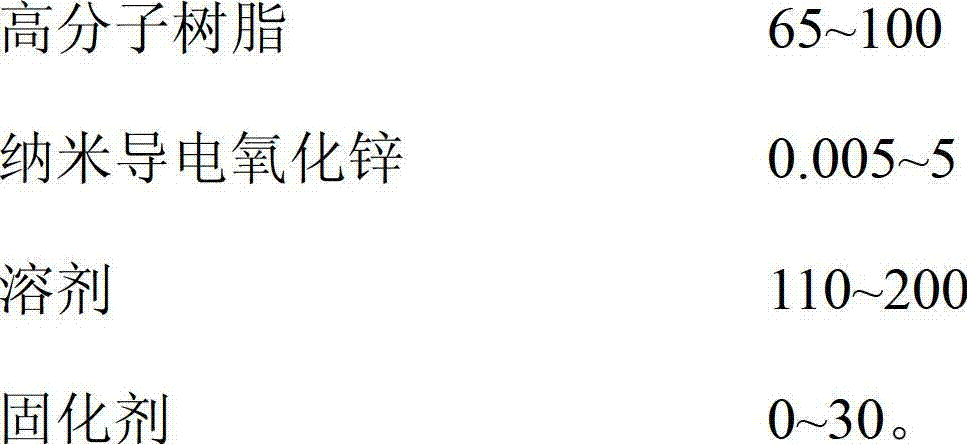

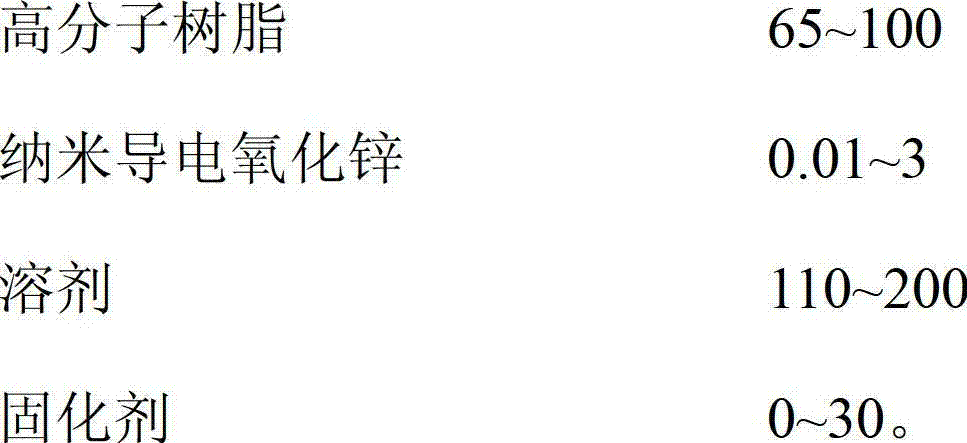

Method used

Image

Examples

Embodiment 1

[0044] Dissolve 70g of epoxy resin (E-44) in 110g of xylene, 25g of Huntsman Jeffamine D-230, 0.45g of nano-conductive zinc oxide (the doping element is aluminum, and the volume resistivity is 1.0×10 1 Ω cm), 0.015g BYK-110, 0.01g BYK-065, 0.0047g CuCl 2 (5×10 -7 mol / g) were added together to the above mixed solution, heated to 40°C and stirred at high speed for 40 minutes at a speed of 1250 rpm, then stopped stirring and cooled to room temperature to obtain a transparent conductive coating. After the coating was applied to the MDF wood board, it was cured at 70°C for 10 minutes to obtain a smooth, continuous and flat coating. The flatness of the coating is 2μm, and the volume resistivity is 6.32×10 2 Ω·cm, adhesion level 0, light transmittance 91%.

Embodiment 2

[0046] 100g of acrylic resin ( M825) was dissolved in 200g of isopropanol and toluene mixture, and then 1.05g of nano-conductive zinc oxide (doping element was gallium, volume resistivity was 3.9×10 0 Ω·cm), P104S, 0.49g FeCl 3 (3×10 -5 mol / g) were added together to the above mixture, ultrasonically dispersed for 30 minutes, heated to 50°C and stirred for 30 minutes, stopped stirring and cooled to room temperature to obtain a transparent conductive coating. After the paint is coated on the PVC board, it is dried at 60°C to obtain a smooth, continuous and flat coating. The flatness of the coating is 1μm, and the volume resistivity is 1.52×10 0 Ω·cm, adhesion level 0, light transmittance 96%.

Embodiment 3

[0048] 95g of water-based polyurethane ( A145) mixed with 150g of water, mixed with 5g of nano-conductive zinc oxide (doping element is cesium, volume resistivity is 2.5×10 -3 Ω cm), 2.5g Efka-766, 1gTEGO Airex970, 0.64g (1×10 -4 mol / g) CuCl was mixed and stirred for 50 minutes, heated to 60°C and stirred for 10 minutes, stopped stirring and cooled to room temperature and emulsified by an emulsifier for 5 minutes to obtain a transparent conductive coating. After the paint is coated on the tin plate, it is dried at 80°C to obtain a smooth, continuous and flat coating. The flatness of the coating is 3 μm, and the volume resistivity is 7.88×10 -4 Ω·cm, adhesion level 0, light transmittance 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com