A kind of gelatinized starch wallpaper glue and its preparation method and application

A gelatinized starch and wallpaper glue technology, which is applied in the field of gelatinized starch technology and adhesives for architectural decoration, can solve the problems of insufficient adhesion between wallpaper and wall surface, inconvenient use, and high cost, and achieve low cost and high production efficiency , The effect of mild production process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

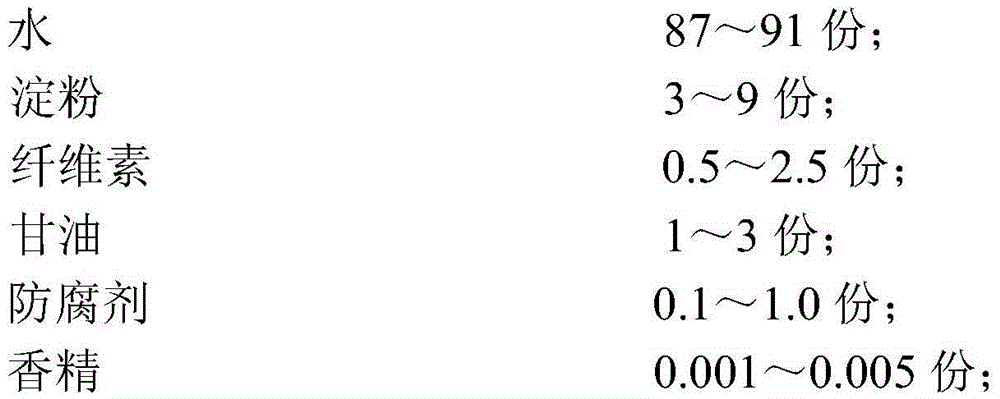

Method used

Image

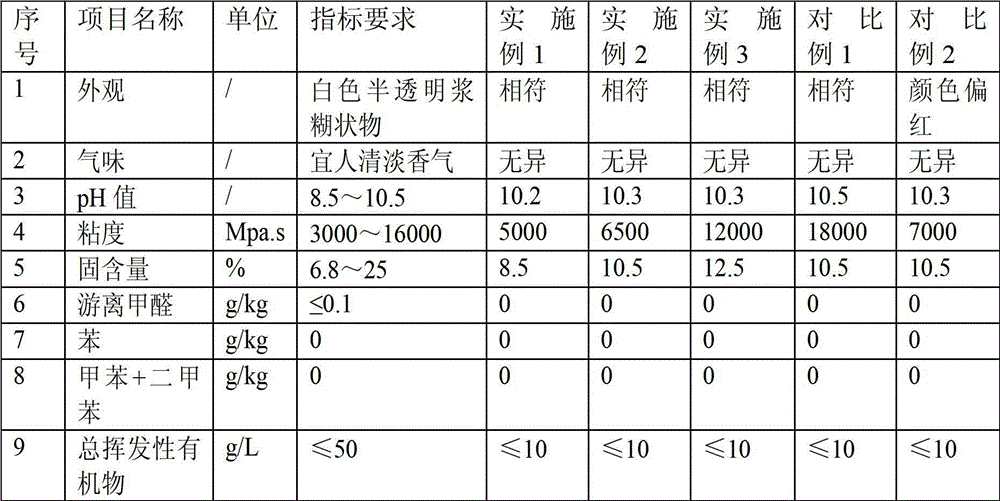

Examples

Embodiment 1

[0031] (1) Add 3kg of cornstarch into a jacketed stainless steel stirring tank filled with 25kg of deionized water (conductivity ≤ 15μs), stir and heat to 80°C, and keep stirring for 15min to make the slurry gelatinized evenly and transparently ;

[0032] (2) Adjust the pH value of the slurry in step (1) to 9, and keep stirring at 80°C for 15 minutes;

[0033] (3) Dissolve 2.5kg of sodium carboxymethylcellulose (viscosity: 800-1200mpa.s, model: OM6, produced by Hebei Chuanchuan Chemical Technology Co., Ltd.) in 63kg of deionized water, and then add it into a stainless steel stirring tank. Stir at 60°C for 15 minutes;

[0034] (4) Add 2kg of glycerin and stir at 55°C for 10 minutes;

[0035] (5) Dissolve 0.5kg of sodium benzoate in 3kg of deionized water, then add it into the stirring tank, and stir at 50°C for 10 minutes;

[0036] (6) Cool down to 45°C, add 5g of essence, stir for 15 minutes, continue to stir, cool to 35°C, discharge, pack, and finish to obtain gelatinized ...

Embodiment 2

[0038] (1) Add 6kg of cornstarch into a jacketed stainless steel stirring tank filled with 50kg of deionized water for heating and cooling, stir and heat to 80°C, and keep stirring for 15 minutes to make the slurry gelatinized evenly and transparently;

[0039] (2) Adjust the pH value of the slurry in step (1) to 10, and keep stirring at 78°C for 15 minutes;

[0040] (3) Dissolve 1.5kg of HEC (model: HHR250) in 36kg of deionized water, then add it into the stirring tank, and stir at 55°C for 15 minutes;

[0041] (4) Add 1kg of glycerin and stir at 55°C for 10 minutes;

[0042] (5) Dissolve 0.1kg of sodium benzoate in 3kg of deionized water, then add it into the stirring tank, and stir at 50°C for 10 minutes;

[0043] (6) Cool down to 45°C, add 1g of essence, stir for 15 minutes, continue to stir, cool to 35°C, discharge, pack, and finish to obtain gelatinized starch wallpaper glue.

Embodiment 3

[0045] (1) Add 9kg of potato starch into a jacketed stainless steel stirring tank with 65kg of deionized water for heating and cooling, stir and heat to 80°C, and keep stirring for 15min to make the slurry gelatinized evenly and transparently;

[0046] (2) Adjust the pH value of the slurry in step (1) to 9.5, and keep stirring at 75°C for 15 minutes;

[0047] (3) Dissolve 0.5kg of CMC (viscosity: 800-1200mpa.s, model: OM6, produced by Hebei Chuanchuan Chemical Technology Co., Ltd.) in 19kg of deionized water, then add it to the stirring tank, and stir at 58°C for 15 minutes;

[0048] (4) Add 3kg of glycerin and stir at 55°C for 10 minutes;

[0049] (5) Dissolve 1kg of sodium benzoate in 3kg of deionized water, then add it into the stirring tank, and stir at 50°C for 10 minutes;

[0050] (6) Cool down to 45°C, add 5g of essence, stir for 15 minutes, continue to stir, cool to 35°C, discharge, pack, and finish to obtain gelatinized starch wallpaper glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com