Connection occlusion agent for oil extraction conical screw rod of screw pump and preparation method thereof

A conical screw and screw pump technology, which is applied in the direction of lubricating compositions, etc., can solve the problems of high labor intensity, increased material costs and man-hours, and long workover cycle, so as to shorten the workover cycle and reduce labor costs. Labor intensity and maintenance cost, effect of copper corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The screw pump oil recovery conical screw connection bite agent of the present invention is composed of the following materials in proportion by weight;

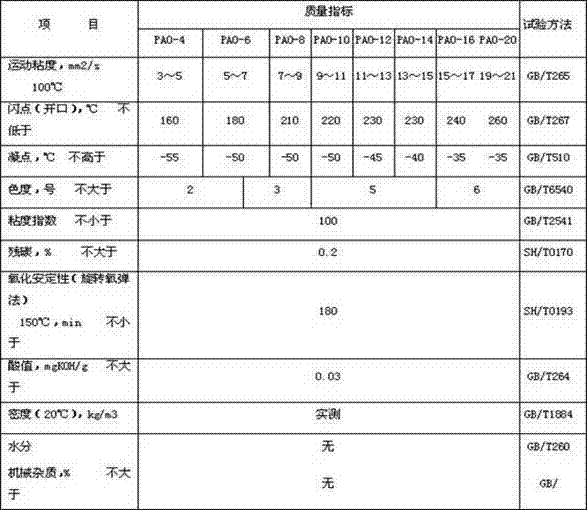

[0031] 4 parts of silver powder, 8 parts of copper powder, 1 part of graphite powder, 35 parts of polyalphaolefin synthetic oil PAO-8 type, 21 parts of diethyl silicone oil, 16 parts of polyisobutylene, 3 parts of fumed silica, 15 parts of titanium dioxide 3 parts, 3 parts of polytetrafluoroethylene powder, 3 parts of antioxidant T501 and 0.2 part of antirust agent T705A;

[0032] Its preparation method is:

[0033] a. Preparation of the first base agent: fully mix and stir polyalphaolefin synthetic oil, diethyl silicone oil and polyisobutylene, then add 0.2-1μm copper powder, and continue stirring at a constant temperature of 120-130°C for 35- After 50 minutes, add 1200 mesh silver powder and continue to stir and disperse for 1 hour;

[0034] b. Preparation of the second base agent: Fully disperse and mix 325-mesh ...

Embodiment 2

[0038] The screw pump oil recovery conical screw connection bite agent of the present invention is composed of the following materials in proportion by weight: 10 parts of silver powder, 2 parts of copper powder, 5 parts of graphite powder, 18 parts of polyα-olefin synthetic oil PAO-8 type , 34 parts of diethyl silicone oil, 4 parts of polyisobutylene, 12 parts of fumed silica, 4 parts of titanium dioxide, 12 parts of polytetrafluoroethylene powder, 0.5 parts of antioxidant T551 and 1 part of antirust agent T705A;

[0039] Its preparation method is with embodiment 1.

Embodiment 3

[0041] The screw pump oil recovery conical screw connection bite agent of the present invention is composed of the following materials in proportion by weight: 8 parts of silver powder, 2 parts of copper powder, 4 parts of graphite powder, 20 parts of polyα-olefin synthetic oil, diethyl 30 parts of silicone oil, 6 parts of polyisobutylene, 11 parts of fumed silica, 5 parts of titanium dioxide, 11 parts of polytetrafluoroethylene powder, 0.5 parts of antioxidant T551 and 1 part of antirust agent T705A;

[0042] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com