A kind of anti-felt shrinkage machine washable finishing method of wool fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

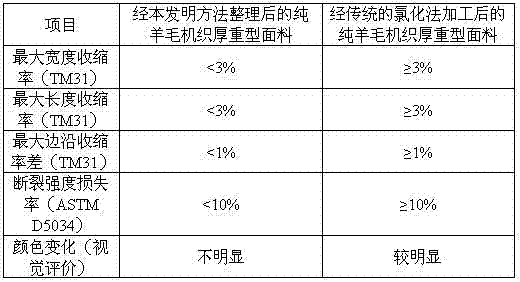

Embodiment 1

[0028] For pure wool woven heavy-duty fabrics (yarn count: 40 / 3×40 / 2; density: 148×192 threads / 10cm; weight: 355g / m 2 ) for anti-felting machine washable finishing treatment, the specific treatment process is:

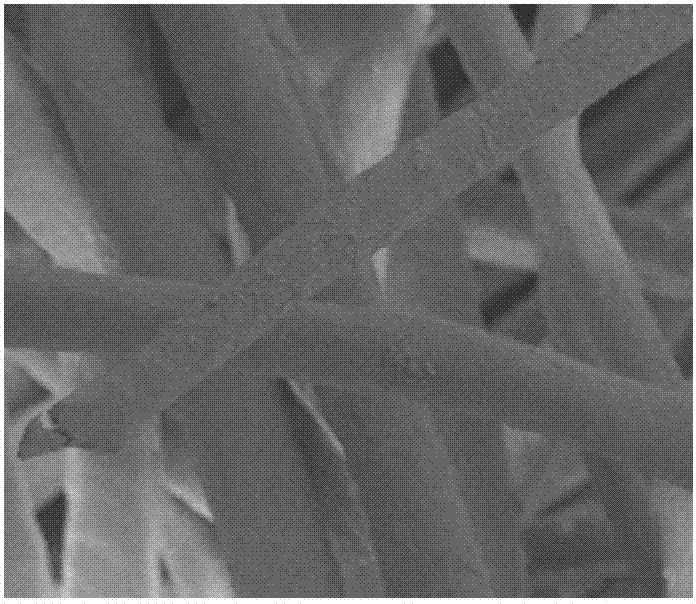

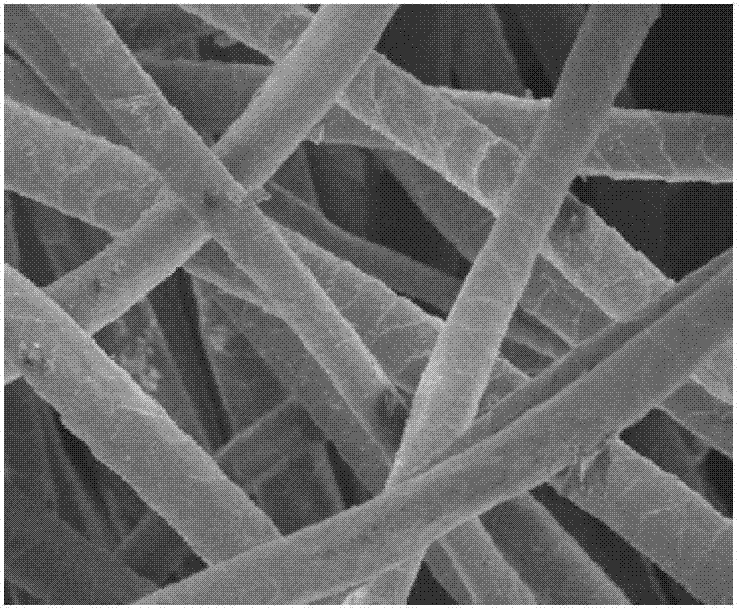

[0029] ① Mild chlorination pretreatment under the action of ultrasonic waves: immerse the wool fabric in a chlorinated solution with a concentration of 1.5% for mild chlorination pretreatment; treatment conditions: the frequency of the ultrasonic processor used is set to 25kHz, and the treatment temperature is 32 ℃, the treatment time is 40 minutes, and the consumption of the chlorinating agent adopted is 1.6% of the weight of the woolen fabric.

[0030] In this embodiment, the ultrasonic processor adopts any existing mature ultrasonic processor; Basolan is used as a chlorinating agent (such as BAOLAN88 (Basolan 88), which is an organic chlorine-releasing compound) to The scale layer on the wool surface is slowly eroded, making the wool surface smooth, making the woo...

Embodiment 2

[0041] For pure wool woven heavy-duty fabrics (yarn count: 40 / 3×40 / 2; density: 148×192 threads / 10cm; weight: 355g / m2 ) for anti-felting machine washable finishing treatment, the specific treatment process is:

[0042] ① Mild chlorination pretreatment under the action of ultrasonic waves: immerse the wool fabric in a chlorinated solution with a concentration of 1% for mild chlorination pretreatment; treatment conditions: the frequency of the ultrasonic processor used is set to 15kHz, and the treatment temperature is 20 ℃, the treatment time is 30 minutes, and the consumption of the chlorinating agent adopted is 1% of the weight of the woolen fabric.

[0043] ②Reductive dechlorination treatment: adding a reducing agent to the chlorinated solution soaked in wool fabric for reduction dechlorination treatment; treatment conditions: the amount of reducing agent is 4% of the weight of the wool fabric, the pH value is adjusted to 6, and the treatment temperature is 20°C, the treatmen...

Embodiment 3

[0049] For pure wool woven heavy-duty fabrics (yarn count: 40 / 3×40 / 2; density: 148×192 threads / 10cm; weight: 355g / m 2 ) for anti-felting machine washable finishing treatment, the specific treatment process is:

[0050] ① Mild chlorination pretreatment under the action of ultrasonic waves: immerse the wool fabric in a chlorinated solution with a concentration of 2% for mild chlorination pretreatment; treatment conditions: the frequency of the ultrasonic processor used is set to 40kHz, and the treatment temperature is 35 ℃, the treatment time is 50 minutes, and the consumption of the chlorinating agent adopted is 2% of the weight of the woolen fabric.

[0051] ②Reductive dechlorination treatment: add a reducing agent to the chlorinated solution soaked in wool fabric for reduction dechlorination treatment; treatment conditions: the amount of reducing agent is 7% of the weight of the wool fabric, the pH value is adjusted to 8.5, and the treatment temperature is 35°C, the treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com