Fabrication method of heat insulating component

A technology for thermal insulation components and production methods, which are applied in thermal insulation, building components, manufacturing tools, etc., can solve the problems of toxic gas and smoke generation, difficulty in fire fighting and rescue work, low bonding strength of surface layer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

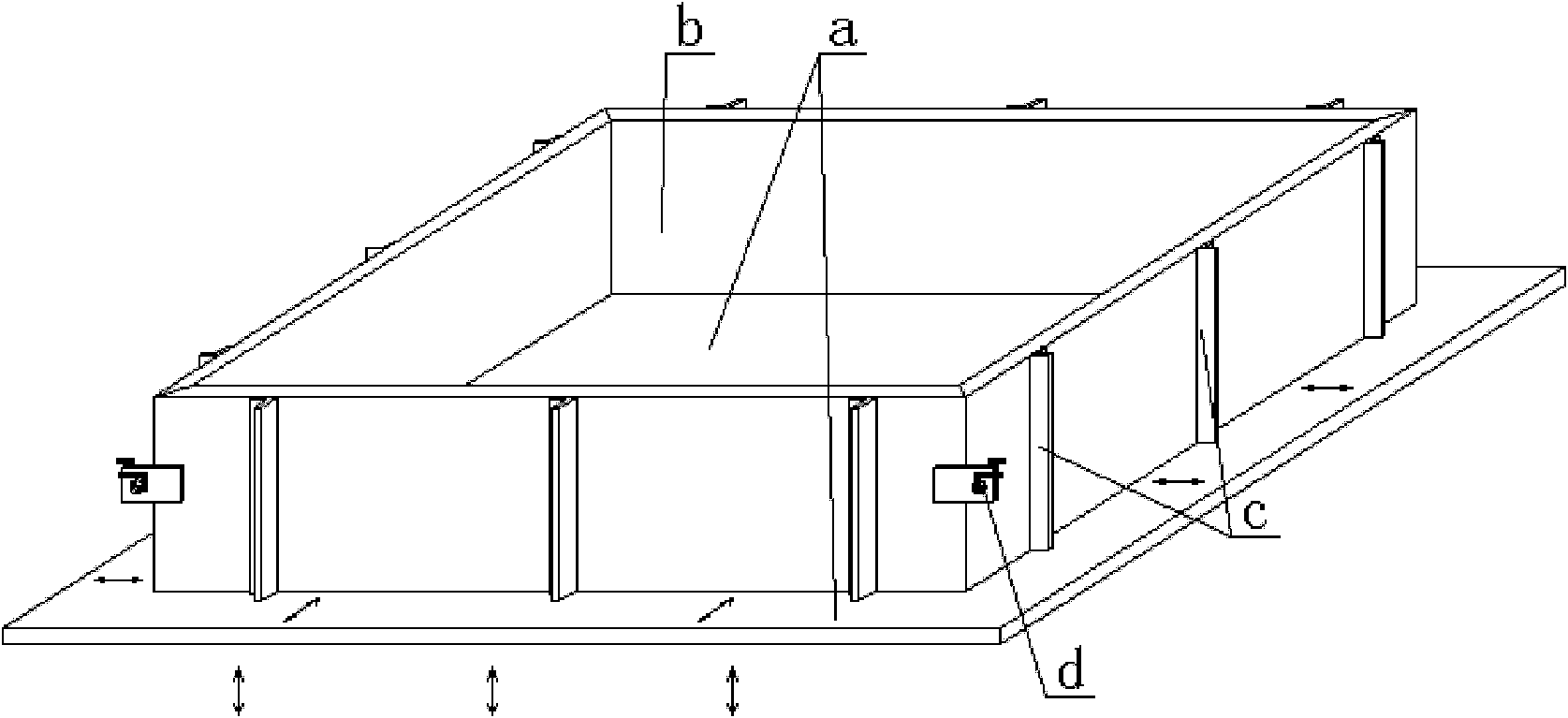

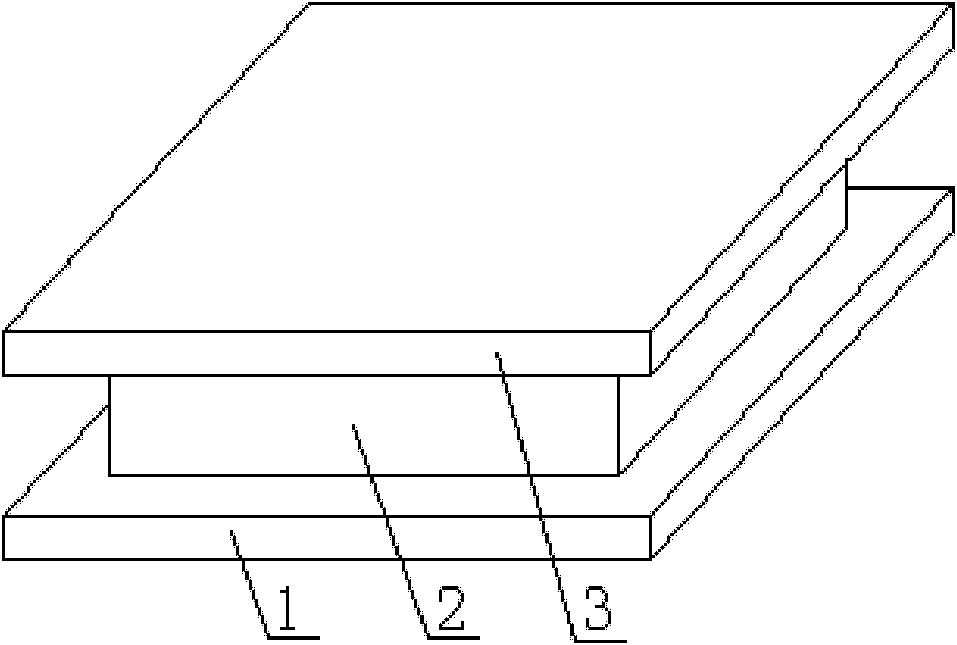

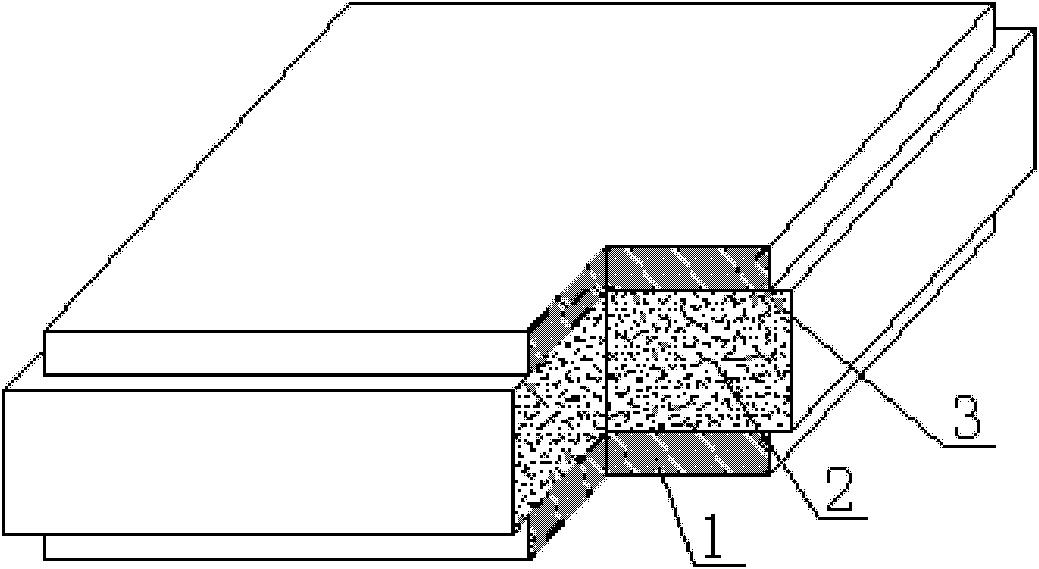

[0045] The technical solution of the present invention is: a method for making a thermal insulation component, which is characterized in that: firstly use thermal insulation material to make the thermal insulation layer 2, and after the thermal insulation layer 2 is cured and formed, pour a hard board 3 on one side of the thermal insulation layer 2, and wait for it to harden After molding, cast the hard board 1 on the other side of the insulation layer 2, and after it hardens and condenses, maintain it to a specified age. figure 1 It is a structural schematic diagram of the mold of the present invention, such as figure 1 The mold shown includes a bottom formwork a and a side formwork b, and each side formwork b is provided with three vertical angle steel reinforcements c on the outside, and the bottom formwork a is a formwork that can move back and fort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com