Horizontal pulverized coal fired boiler with two furnace pipes

A pulverized coal boiler and dual-furnace technology, which is applied in steam boilers, boiler smoke pipes/fire pipes, steam generation, etc., can solve the problems of increased processing difficulty, increased boiler volume, easy coking, etc., and achieves easy operation and storage. The effect of transportation, short production cycle and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

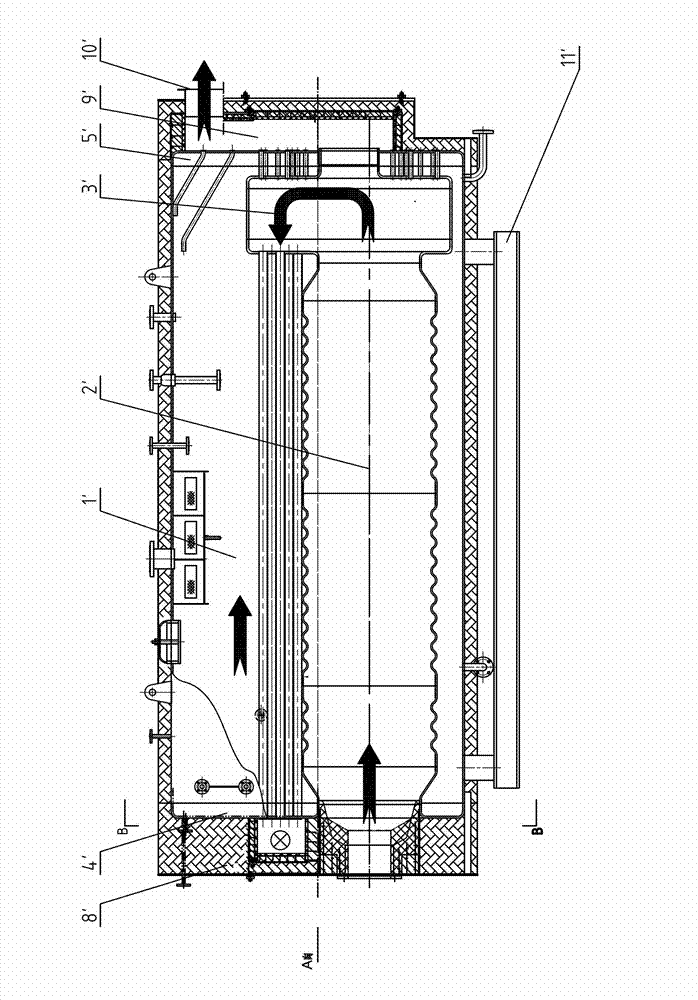

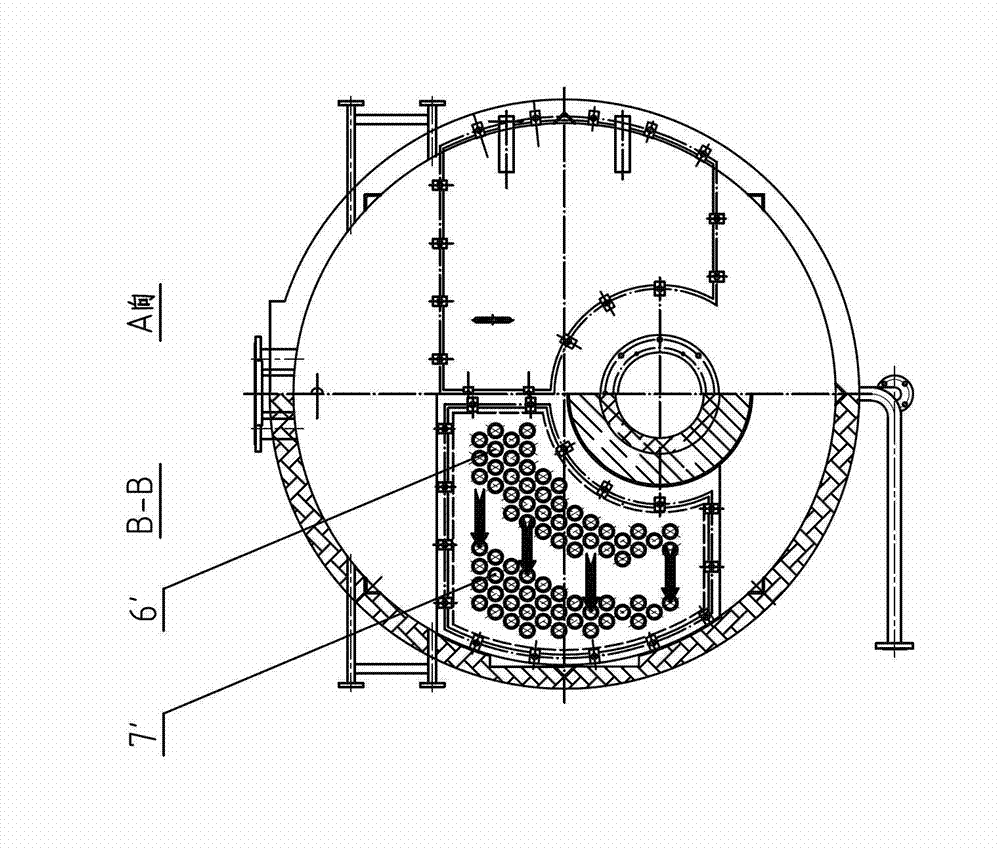

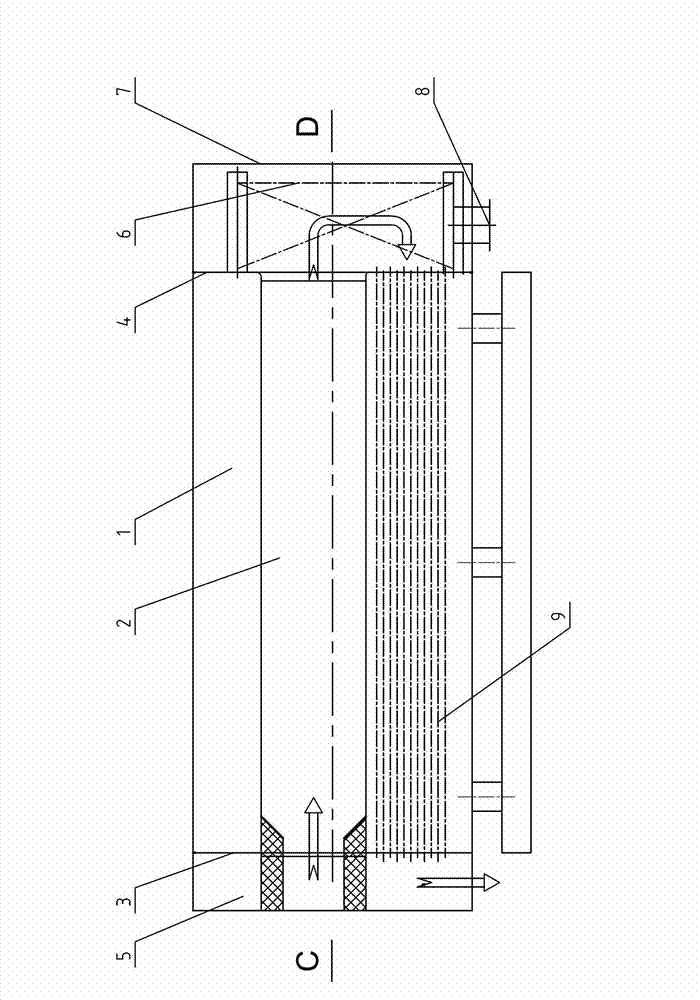

[0037] refer to Figure 1 to Figure 6 , a horizontal double-furnace pulverized-coal boiler of the present invention comprises a pot shell body 1 and an external hanging body 11, and the described pot shell body 1 is provided with a double furnace body 2, a front tube plate 3, and a rear tube Plate 4, front smoke box 5, membrane wall back-combustion chamber 6, outer cladding plate 7 and second return smoke pipe 9, said double furnace gall 2 and second return smoke pipe 9 pass through said front tube plate 3 and The rear tube plate 4 is fixed in the boiler shell shell 1; the front smoke box 6 and the outer cladding plate 7 are respectively arranged at the front and rear ends of the boiler shell 1; the front end of the second return smoke pipe 9 is connected to the The front smoke box 5 is in communication, and the rear end is in communication with the double furnace 2 through the membrane wall back-combustion chamber 6; The lower side: the bottom of the membrane wall recombusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com