Dual-heat source heat pump water heating all-in-one machine employing dual four-way valves for switching

A double four-way valve, heat pump hot water technology, applied in refrigerators, fluid circulation arrangements, lighting and heating equipment, etc., can solve problems such as insufficient refrigerant volume, poor heat absorption capacity, and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

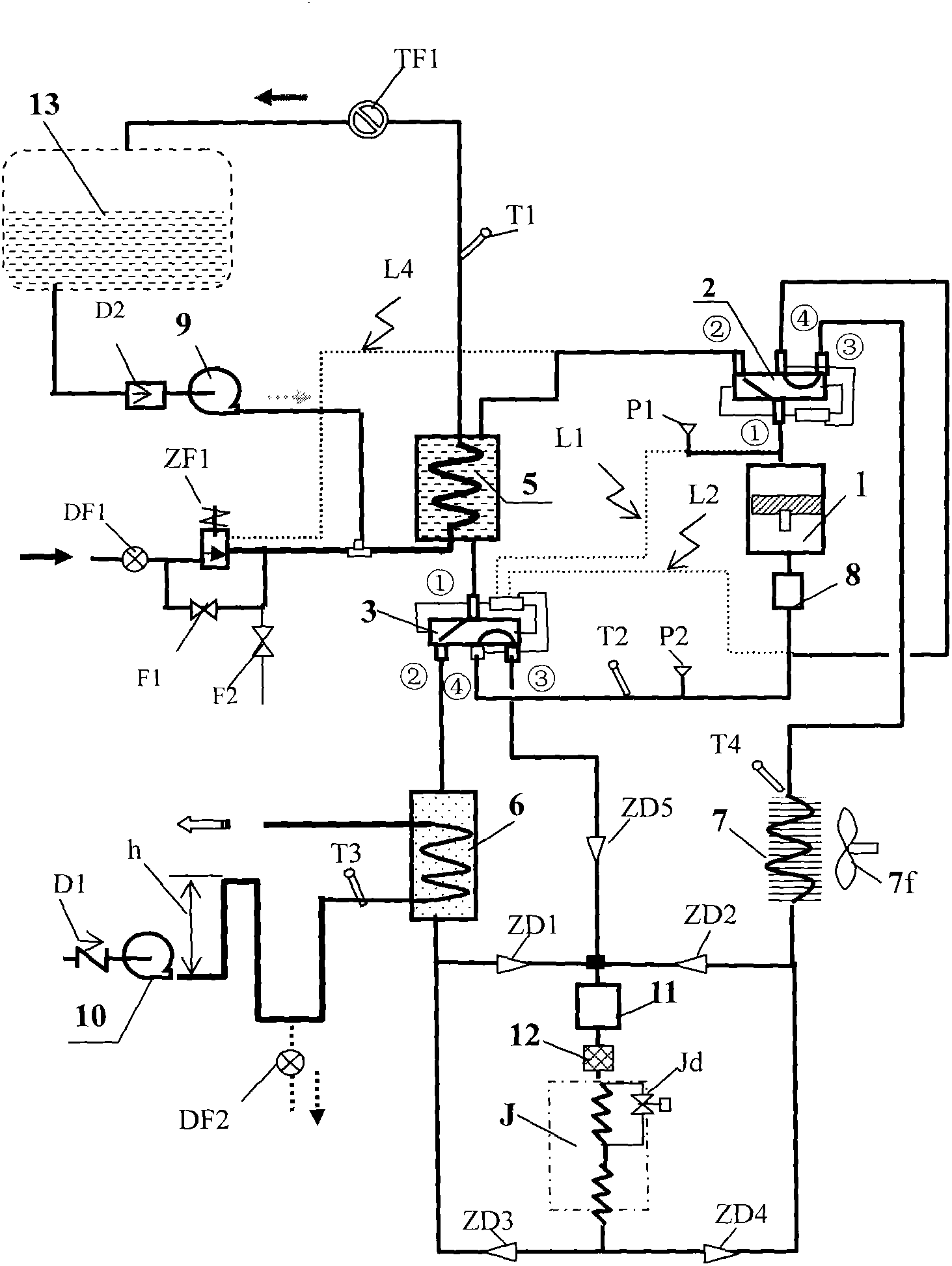

[0045] Embodiment 1, figure 1Shown is a schematic diagram of the basic structure and an explanatory diagram of the working principle of the dual-source heat pump hot water integrated machine switched by double four-way valves in Embodiment 1 of the present invention. It is two four-way valves, five one-way valves, and three separate cycles of refrigerants. Loop system, refrigerant loop system, including compressor 1, first and second four-way valves 2, 3, hot water heat exchanger 5, water source heat exchanger 6, air source heat exchanger 7, liquid storage 11, filter Device 12, throttle J, gas-liquid separator 8, first, second, third, fourth, fifth one-way valves ZD1, ZD2, ZD3, ZD4, ZD5; The gas port is connected to the first interface ① of the first four-way valve 2; the second and third interfaces ② and ③ of the first four-way valve 2 are respectively connected to the refrigerant inlet of the hot water heat exchanger 5 and the air source heat exchanger 7's upper port connec...

Embodiment 2

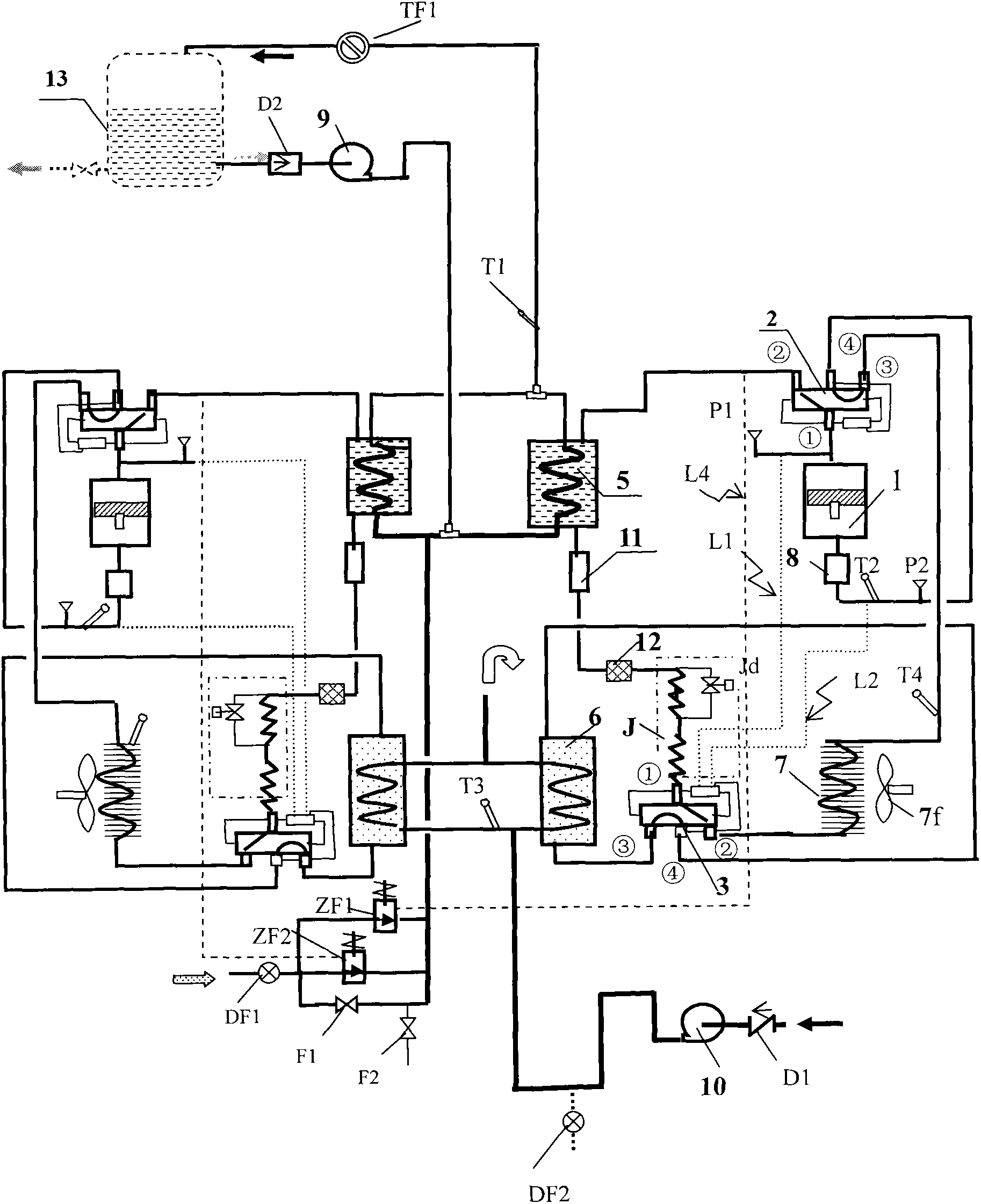

[0055] Embodiment 2, figure 2 It is the embodiment 2 of the dual heat source heat pump hot water integrated machine switched by double four-way valves in the present invention. There are two sets of two four-way valves for single air source, water source + air source in series, and defrosting three separate cycles of refrigerants Schematic diagram of the basic structure of the loop system.

[0056] like figure 2 As shown, the connection mode of the refrigerant circuit is: the first, second, third, and fourth ports ①, ②, ③, and ④ of the first four-way valve 2 are respectively connected to the exhaust port of the compressor 1 and the hot water heat exchanger 5, the upper end interface of the air source heat exchanger 7, and the fourth interface of the second four-way valve 3; After 12, it is connected to the inlet of throttle J; the first, second, and third ports ①, ②, and ③ of the second four-way valve 3 are respectively connected to the outlet of throttle J and the lower e...

Embodiment 3

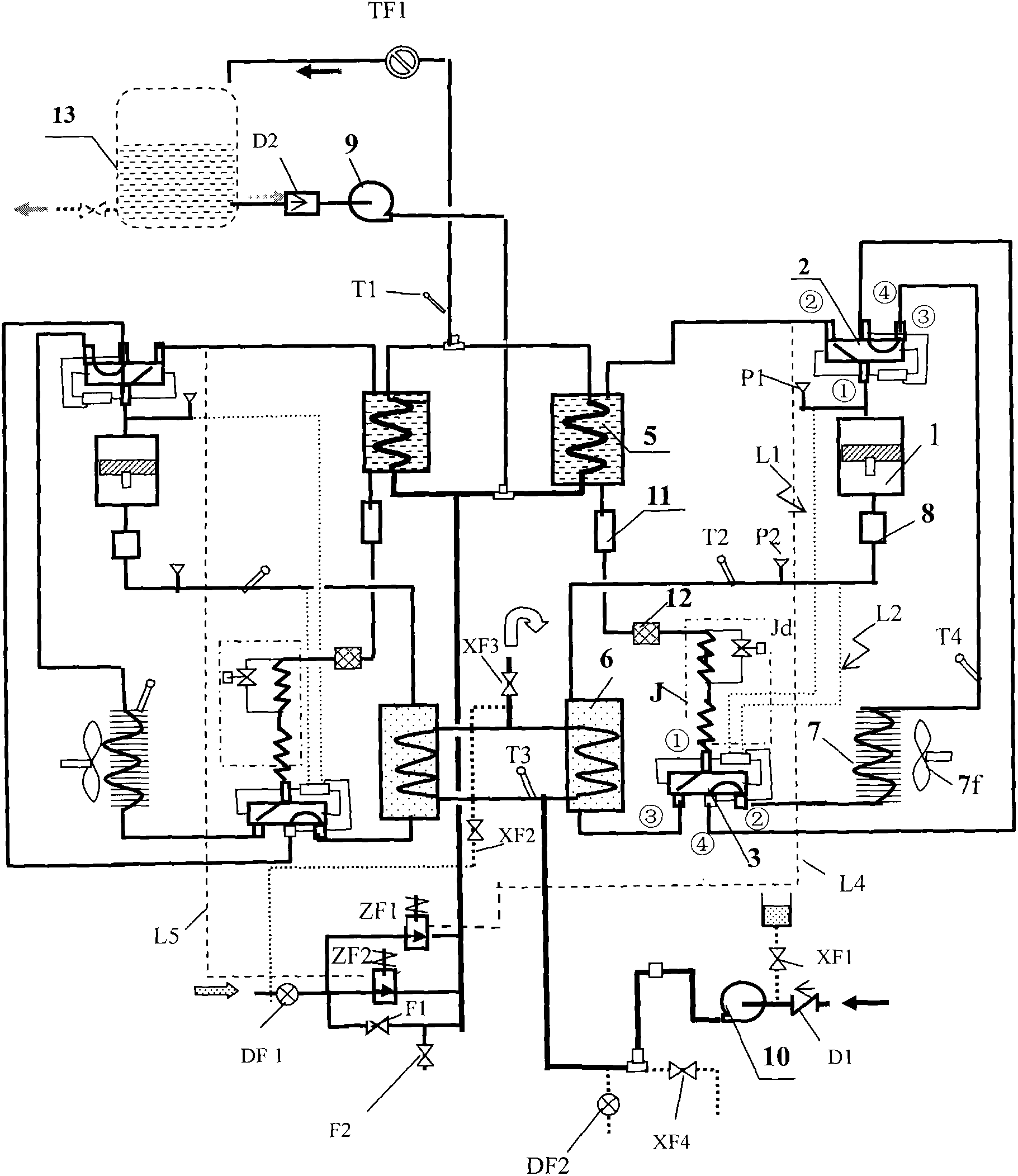

[0062] Embodiment 3, image 3 It is the embodiment 3 of the dual heat source heat pump hot water integrated machine switched by double four-way valves in the present invention. There are two sets of two four-way valves with single water source, air source + water source in series, and defrosting three separate cycles of refrigerant circuits Schematic diagram of the basic structure of the system.

[0063] Such as image 3 shown in image 3 Take the refrigerant circulation system in the middle right half as an example to illustrate the structure of the refrigerant circuit system: the first, second, third, and fourth ①, ②, ③, and ④ ports of the first four-way valve 2 are respectively connected to the discharge ports of the compressor 1. The air port, the refrigerant inlet of the hot water heat exchanger 5, the upper end interface of the air source heat exchanger 7, and the fourth interface ④ of the second four-way valve 3 are connected; the refrigerant outlet of the hot water h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com