Condensation photovoltaic module with hollow glass packaging structure

A technology of glass encapsulation and concentrating photovoltaics, applied in the field of solar photovoltaics, can solve the problems of encapsulation quality affecting the efficiency of CPV components, affecting the concentrating light path and service life of components, corrosion of circuit components of CPV components, etc., to ensure stability and photoelectricity Conversion efficiency, reduced deformation, and good protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

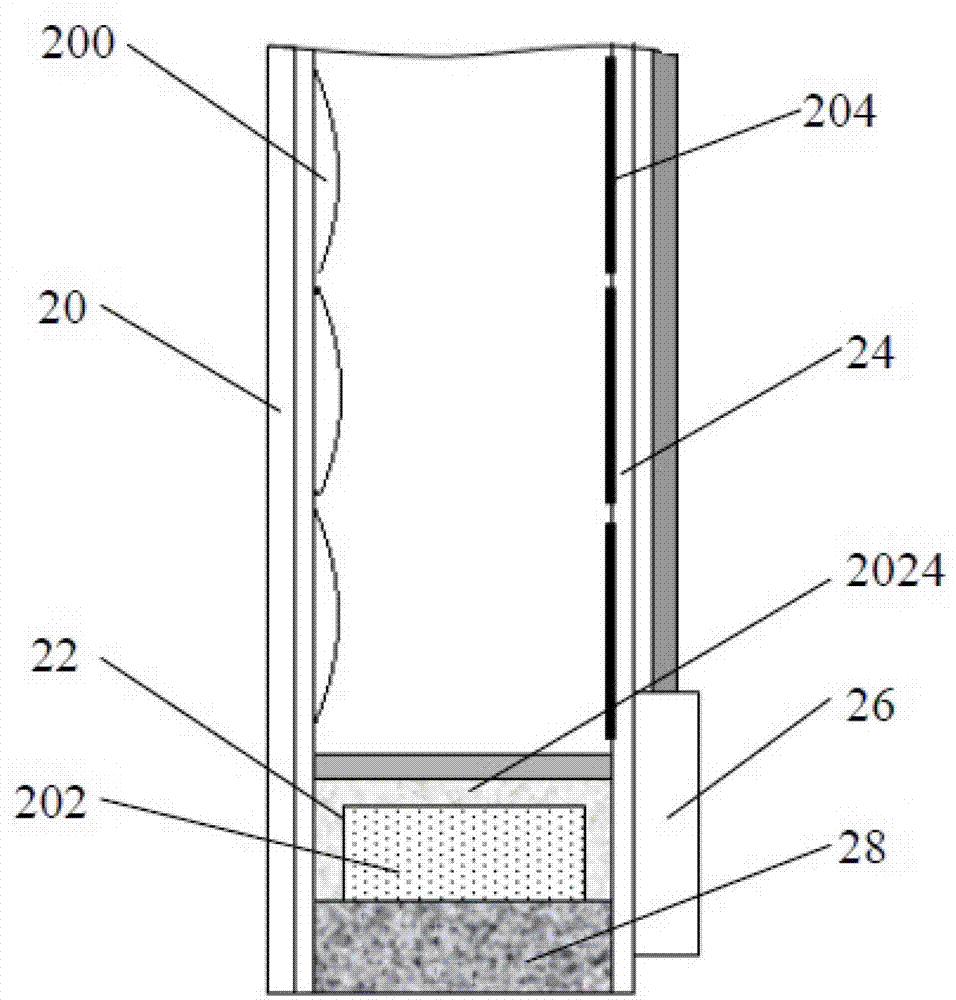

[0016] Such as figure 2 Shown is a schematic structural view of a concentrating photovoltaic module with a hollow glass encapsulation structure according to an embodiment of the present invention, the concentrating photovoltaic module includes: a concentrating lens panel 20 and a concentrating lens 200 arranged thereon, with a solar The circuit base plate 24 of the battery 204 is located at the junction box 26 on the back of the assembly, and between the condenser lens panel 20 and the circuit base plate 24 passes through the hollow aluminum spacer bar 22 and the hot-melt butyl resin coated on the hollow aluminum spacer bar 22 Glue 2024 for encapsulation, the interior of the hollow aluminum spacer 22 is filled with molecular sieve 202, and the surrounding frame of the light concentrating module is filled with silicone glue 28 to seal and bond the edges. In a preferred embodiment, the thickness of the hot-melt butyl adhesive 2024 coated on the hollow aluminum spacers 22 is 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com