Preparation method of titanium dioxide-mesoporous polymer nano porous composite visible light catalytic material

A nanoporous, titanium dioxide technology, applied in the field of material science, can solve the problems of unfavorable product separation, poor thermal stability, etc., and achieve the effects of excellent visible light catalytic degradation ability, good adsorption performance, and excellent visible light catalytic degradation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

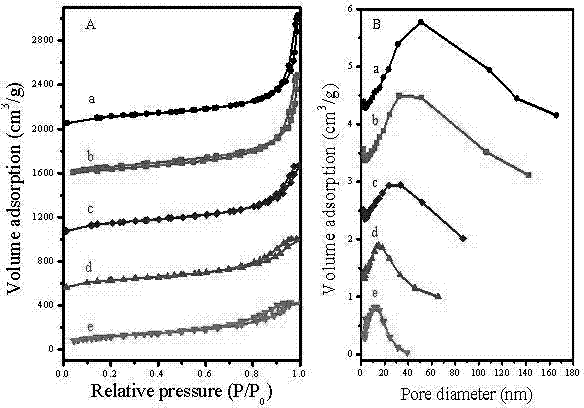

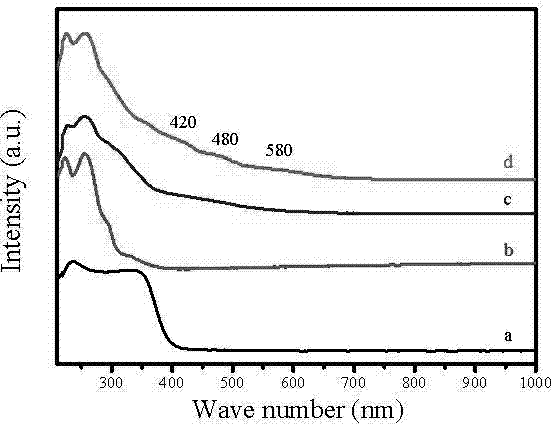

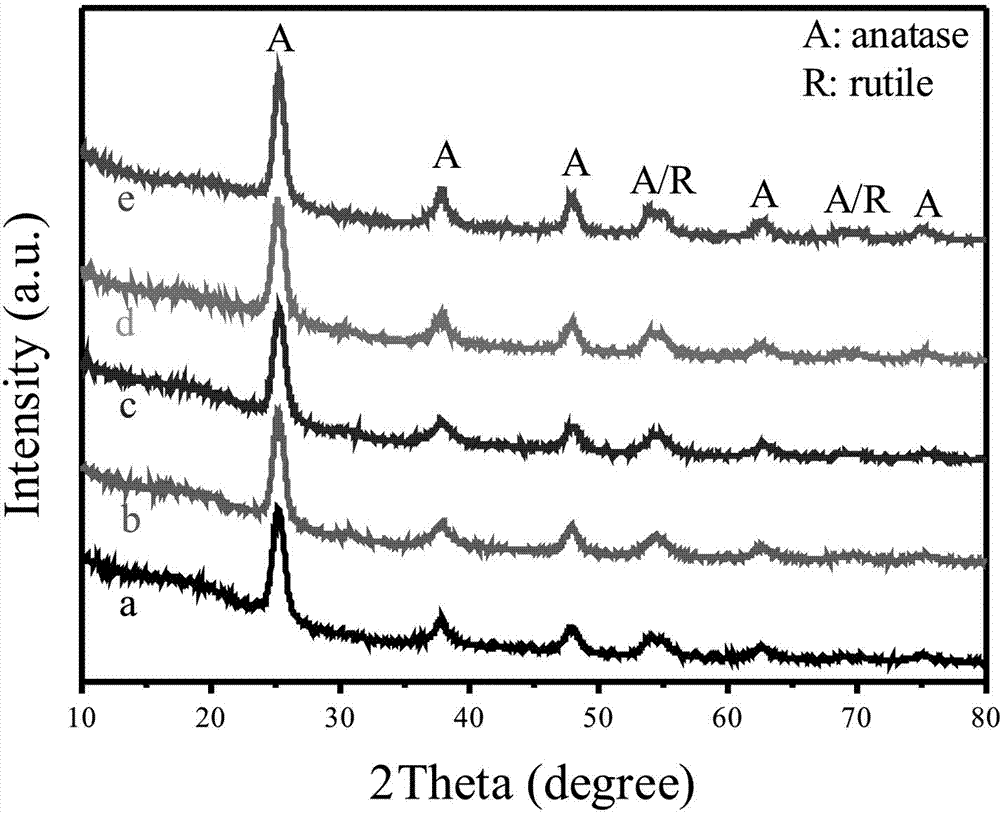

[0034] Firstly, titanium dioxide-mesoporous polymer nanoporous composite visible light catalytic material, PDVB-VI-TiO, was synthesized by using ethyl acetate solvent and imidazole as functional monomers. 2 -xs (where xs represents the molar ratio of titanium species to imidazole in the material).

[0035] 2.0 g DVB, 0.72 g 1-vinylimidazole (VI) were added to a mixed solution containing 0.065 g AIBN and 25 mL ethyl acetate, then 2.5 mL n-butyl titanate (TBOT), stirred at room temperature for 3 hours, 100 ℃ hydrothermal treatment for 24 h, a brownish-yellow blocky solid was obtained. In order to fully crystallize the titanium dioxide in the material, open the lid of the reactor after hydrothermal treatment, add 2-3mL of water, continue the hydrothermal treatment at 160°C for 24 hours, take it out, open the lid, and volatilize the solvent to obtain PDVB-VI-TiO 2 -0.92. The DVB / AIBN / VI / TBOT / ethyl acetate (molar ratio) during the synthesis was 1 / 0.026 / 0.5 / 0.46 / 16.7.

Embodiment 2

[0037] Titanium dioxide-mesoporous polymer nanoporous composite visible light catalytic materials were synthesized with ethyl acetate solvent and imidazole as functional monomers, and the content of titanium species in the materials was adjusted.

[0038]2.0 g DVB, 0.72 g 1-vinylimidazole (VI) were added to a mixed solution containing 0.065 g AIBN and 25 mL ethyl acetate, then 1.25 mL n-butyl titanate (TBOT), stirred at room temperature for 3 hours, 100 After hydrothermal treatment at ℃ for 24 h, a brownish-yellow block solid was obtained. In order to fully crystallize the titanium dioxide in the material, open the lid of the reactor after hydrothermal treatment, add 2-3mL water, continue the hydrothermal treatment at 150℃ for 24 hours, take it out, and open Cover, volatilize the solvent to get PDVB-VI-TiO 2 -0.46. The DVB / AIBN / VI / TBOT / ethyl acetate (molar ratio) during the synthesis was 1 / 0.026 / 0.5 / 0.23 / 16.7.

Embodiment 3

[0040] In the process of synthesizing titanium dioxide-mesoporous polymer nanoporous composite visible light catalytic materials, the synthesis solvent in the synthesis process of materials is modulated.

[0041] Add 2.0 g DVB, 0.72 g 1-vinylimidazole (VI) to a mixed solution containing 0.065 g AIBN and 20-30 mL tetrahydrofuran, then add 2.5 mL n-butyl titanate (TBOT), stir at room temperature for 3 hours, 100 ℃ hydrothermal treatment for 24 h, a brownish-yellow blocky solid was obtained. In order to fully crystallize the titanium dioxide in the material, open the lid of the reaction kettle after hydrothermal treatment, add 2-3mL water, continue the hydrothermal treatment at 150℃ for 24 hours, take it out, and open Cover, volatilize the solvent to get PDVB-VI-TiO 2 -0.92. DVB / AIBN / VI / TBOT / THF was 1 / 0.026 / 0.5 / 0.46 / 16.7 during the synthesis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com