Cascade grinding wheel slice and production method thereof

A stacked, grinding wheel technology, applied in the field of abrasives, can solve the problems of poor durability of grinding wheel slices, increased cutting costs for users, and high consumption of grinding wheel slices. It achieves good dimensional stability, improves wetting and bonding performance, and improves The effect of cut ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

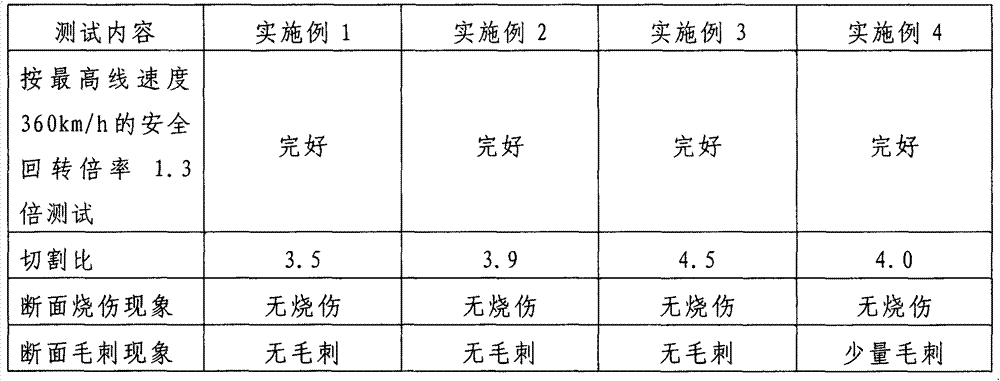

Examples

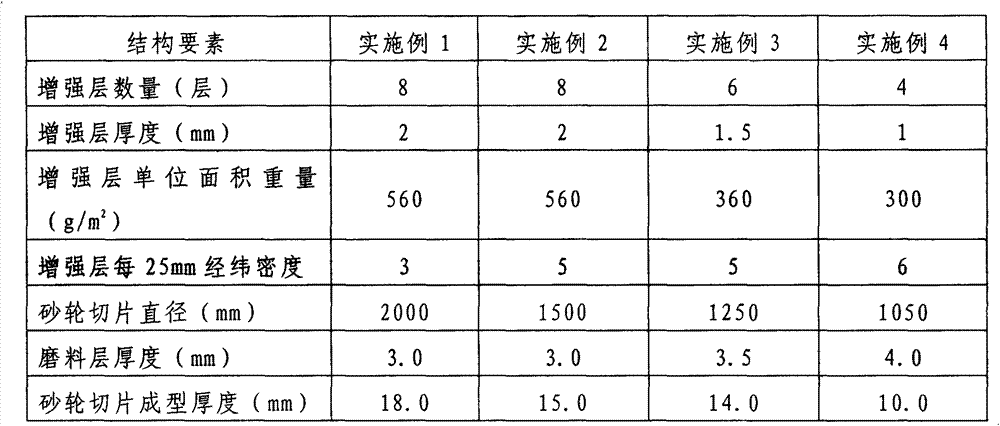

preparation example Construction

[0044] The present invention also includes the preparation method of laminated grinding wheel slice, and it implements according to the following steps:

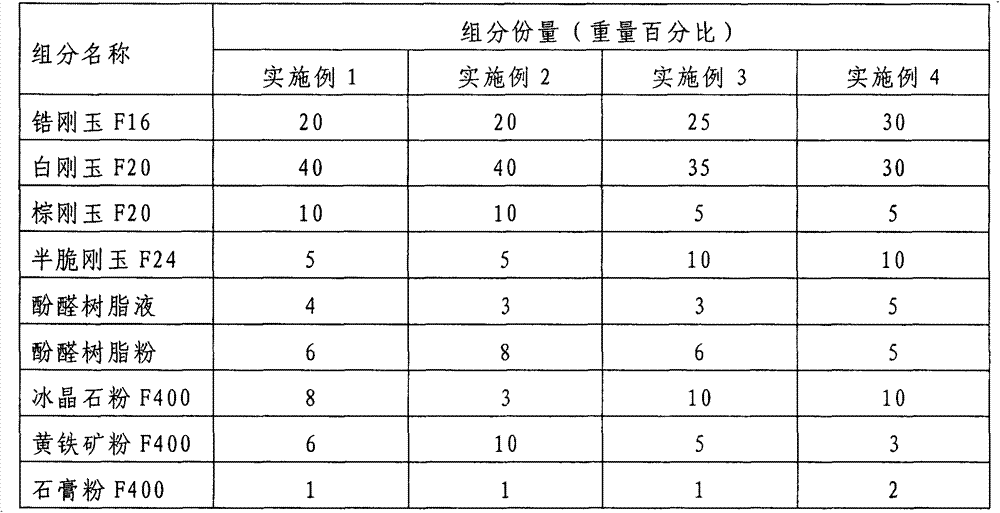

[0045] A. mix

[0046] Add the white corundum, zirconium corundum, brown corundum and semi-brittle corundum measured according to the ratio into the rough mixing cylinder of the mixer, mix for 2 to 10 minutes, then add the measured phenolic resin solution, and continue to mix for 5 to 15 minutes to obtain a rough mix. material; add the measured cryolite powder, pyrite powder, and phenolic resin powder into the fine mixing cylinder of the mixer, and mix for 5 to 10 minutes to obtain the fine mixture, then gradually add the coarse mixture to the fine mixture, and mix for 10 minutes. ~ 15 minutes to get the abrasive layer.

[0047] B. Sieving

[0048] After the abrasive material is out of the cylinder, it is sieved with an 8-mesh sieve.

[0049] C. Ripening treatment

[0050] Place the sieved abrasive layer material at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com