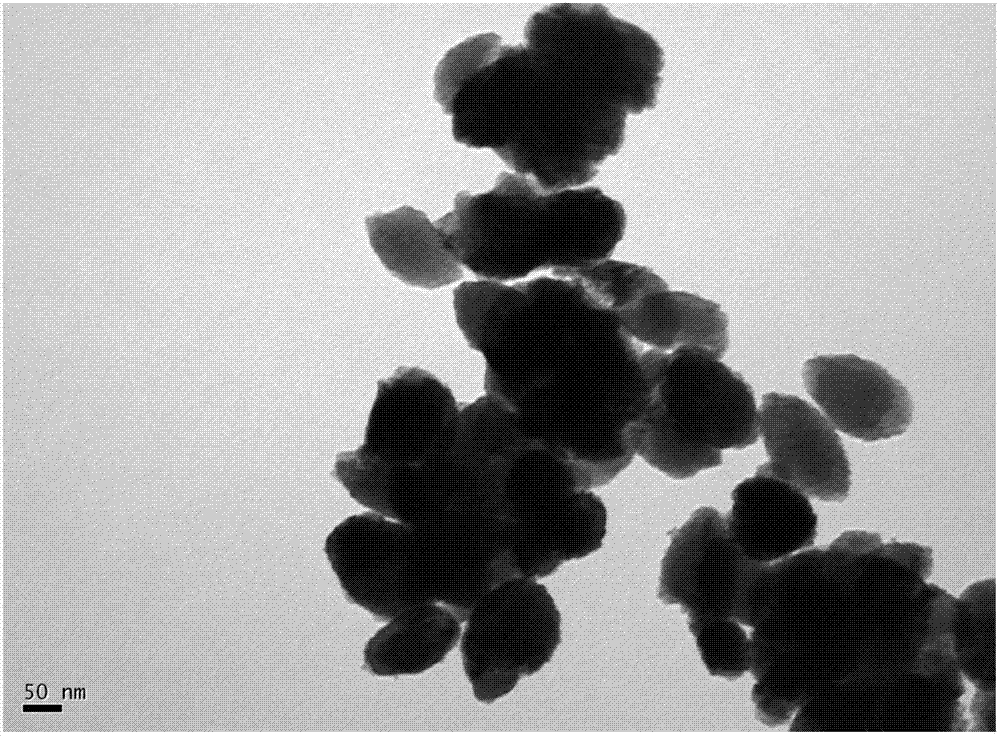

Preparation method of ellipsoidal particle size-controllable alpha-Fe2O3 nano particle

A nanoparticle and ellipsoidal technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of uneven particle size, narrow controllable range of particle size, and poor operability and other issues, to achieve the effect of low cost, easy access to raw materials, and wide controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Ellipsoid particle size controllable α-Fe of the present invention 2 o 3 A method for preparing nanoparticles, comprising the following steps:

[0027] a. Dissolving ferric salt and hydroxyl or / and carbonyl surfactant in water or ethanol aqueous solution;

[0028] b. Heating to 100-180°C, reacting for 0.5-5 hours to prepare α-Fe 2 o 3 Seed crystal; the above reaction is generally carried out in a reactor, and the solution is in a boiling state, and the Fe 3+ Hydrolysis and [Fe(OH) 3 ] n Polycondensation leads to α-Fe 2 o 3 Seed generation;

[0029] c. Adjust pH=9~11;

[0030] d. The filtered solids are washed and dispersed in water or ethanol aqueous solution, and stirred for 10-60 minutes at a speed of not less than 500rpm for beating;

[0031] e. Heating to 100-180°C for 0.5-6 hours; the reaction is generally carried out in a reaction kettle. In the boiling state, the hydroxyl or carbonyl of the surfactant is easy to react with Fe(OH) 3 The -OH forms hy...

Embodiment 1

[0043] The ellipsoidal particle diameter of this embodiment is controllable α-Fe 2 o 3 A method for preparing nanoparticles, comprising the following steps:

[0044] a. Take ferric nitrate by weighing 2.5 moles, and take by weighing 30 grams of polyvinyl alcohol as surfactant, both of which are dissolved in water to form 5L of solution;

[0045] b. Heating to 150°C, reacting for 3 hours, and preparing α-Fe 2 o 3 Seed crystal; the above reaction is generally carried out in a reactor, and the solution is in a boiling state, and the Fe 3+ Hydrolysis and [Fe(OH) 3 ] n Polycondensation leads to α-Fe 2 o 3 Seed generation;

[0046] c. Add 1mol / L NaOH until the pH reaches 10;

[0047] d. The filtered solid forms a filter cake, which is washed with water and dispersed in 5L of water, and mechanically stirred at a speed of 3000rpm for 10 minutes to make a slurry;

[0048] e. Heating to 150°C for 3 hours; the reaction is generally carried out in a reaction kettle. In the b...

Embodiment 2

[0052] The ellipsoidal particle diameter of this embodiment is controllable α-Fe 2 o 3 A method for preparing nanoparticles, comprising the following steps:

[0053] a. Take ferric chloride by weighing 5 moles, and take by weighing 500 grams of ethylene glycol as surfactant, both are dissolved in the aqueous solution of ethanol to form solution 5L;

[0054] b. Heating to 100°C, reacting for 6 hours, and preparing α-Fe 2 o 3 Seed crystal; the above reaction is generally carried out in a reactor, and the solution is in a boiling state, and the Fe 3+ Hydrolysis and [Fe(OH) 3 ] n Polycondensation leads to α-Fe 2 o 3 Seed generation;

[0055] c. Add 1mol / L NaOH until the pH reaches 9;

[0056] d. The filtered solid forms a filter cake, which is washed with water and dispersed in a 5L ethanol aqueous solution, and mechanically stirred at a speed of 500 rpm for 60 minutes to make a slurry;

[0057] e. Heating to 100°C for 6 hours; the reaction is generally carried out i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com