Diffusion connection method of carbide ceramic

A diffusion bonding and carbide technology, applied in the field of carbide ceramic welding, can solve problems such as uneven structure, and achieve the effects of improving high temperature mechanical properties, reliable connection, and improving room temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

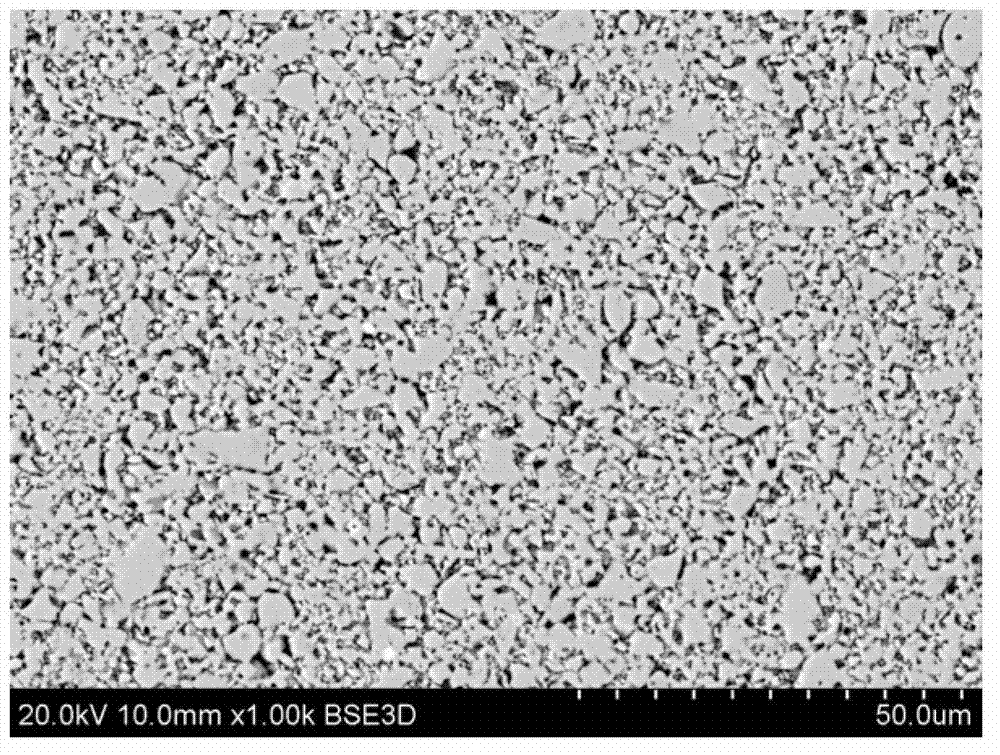

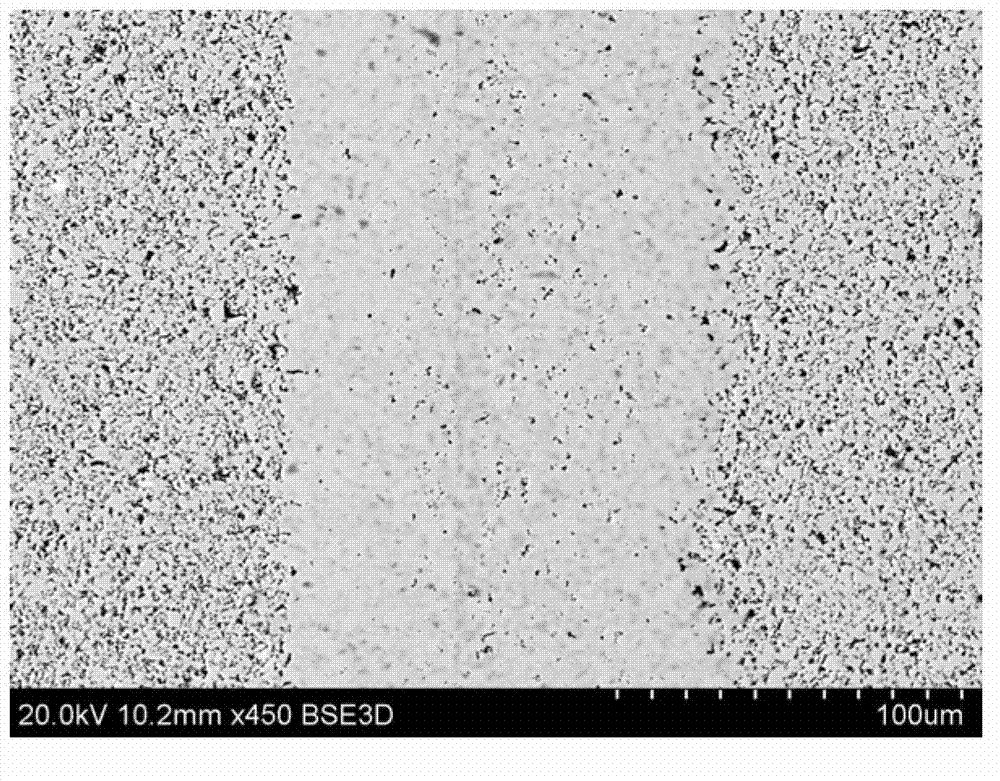

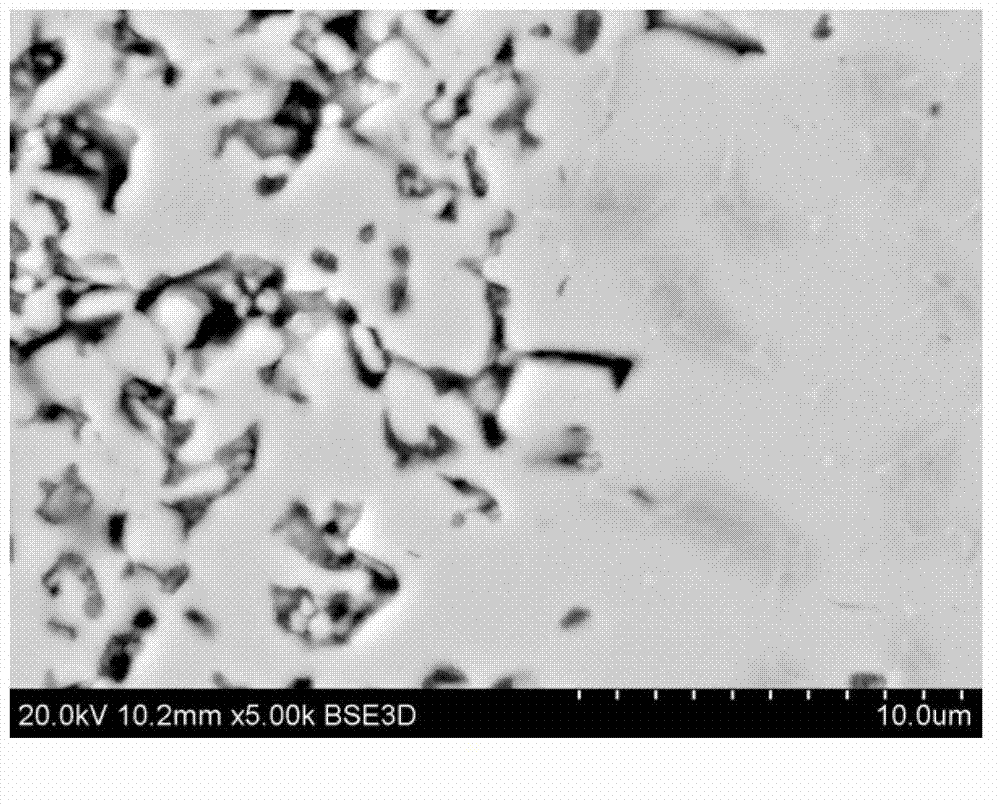

[0010] Specific Embodiment 1: This embodiment is a diffusion bonding method of carbide ceramics, which is specifically completed according to the following steps: 1. Surface cleaning: first use mechanical grinding or organic solution to treat the surfaces of two carbide ceramics to be welded. Carry out cleaning, obtain the carbide ceramics after two surface cleanings; Two, electroplating Ni metal layer: adopt electroplating method to electroplating Ni metal layer on the carbide ceramic surface after two surface cleanings, the thickness of the Ni metal layer of electroplating is 2 μ m~50 μ m, obtain Two carbide ceramics with a Ni metal layer; 3. Welding: Firstly, two carbide ceramics with a Ni metal layer are fixed butt jointed, then assembled in a graphite fixture and placed in a vacuum diffusion welding furnace, and then placed in a vacuum diffusion welding furnace. The welding pressure is 5MPa~20MPa, and the vacuum degree is 0.5×10 -3 Pa~1.5×10 -3 Pa and heating rate of 10 ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the carbide ceramics to be welded described in step one is ZrC ceramics, TiC ceramics, SiC ceramics, WC ceramics, HfC ceramics, TaC ceramics, ZrC ceramics -SiC composite ceramics, ZrC-ZrB 2 -SiC composite ceramics, TiC-SiC composite ceramics or SiC-ZrB2 Composite ceramics. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the adopting process of the mechanical grinding described in step one is as follows: first use 240#~1000# diamond grinding disc to polish the surface of the ceramic material to be welded , and then use 800#~1200# water sandpaper to further finely grind the surface to be welded, that is, complete mechanical grinding. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com