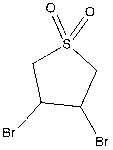

Synthetic method of 3,4-dibromo sulfolane

A technology of dibromosulfolane and a synthesis method, which is applied in the field of synthesizing 3,4-dibromosulfolane, can solve the problems of poor heat and mass transfer, difficulty in stirring, difficult industrialized production and the like, and achieves the effects of simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Add 59g of sulfolene and 59g of carbon tetrachloride into a round-bottomed four-necked flask equipped with a dropping funnel, condenser, stirrer and thermometer, raise the temperature to 90°C under stirring, add 80g of bromine dropwise, drop for about 30 minutes After the reaction is completed, the crude product liquid of 3,4-dibromosulfolane is obtained, the crude product liquid is filtered, the obtained solid is washed with carbon tetrachloride for 2 to 3 times, and the washed solid is dried 137.1 g of a white solid was obtained, which was 3,4-dibromosulfolane, with a purity of 99.5%, a melting point of 141-142°C, and a yield of 98.6%.

Embodiment 2

[0016] Example 2 Add 59g of sulfolene and 100g of carbon tetrachloride into a round-bottomed four-necked flask equipped with a dropping funnel, condenser, stirrer and thermometer, raise the temperature to 90°C under stirring, add 160g of bromine dropwise, drop for about 50 minutes After the reaction is completed, the crude product liquid of 3,4-dibromosulfolane is obtained, the crude product liquid is filtered, the obtained solid is washed with carbon tetrachloride for 2 to 3 times, and the washed solid is dried 136.2 g of a white solid was obtained, which was 3,4-dibromosulfolane, with a purity of 99.4%, a melting point of 141-142°C, and a yield of 98%.

Embodiment 3

[0017] Example 3 Add 59g of sulfolene and 100g of benzene into a round-bottomed four-necked flask equipped with a dropping funnel, a condenser, a stirrer and a thermometer, raise the temperature to 75°C while stirring, add 80g of bromine dropwise, drop it in about 30 minutes, continue Reacted at 75°C for 3 hours. After the reaction, the crude product liquid of 3,4-dibromosulfolane was obtained. The crude product liquid was filtered, and the obtained solid was washed twice with benzene, and the washed solid was dried to obtain 136.6 g of white solid. The solid is 3,4-dibromosulfolane with a purity of 99.3%, a melting point of 141-142°C and a yield of 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com