Synthesis process of acid liquor thickening agent on basis of control of PH value of reaction system

A technology of acid thickener and reaction system, applied in coating and other directions, can solve the problems of reducing the degree of polymerization and reducing the molecular weight of the product, and achieve the effects of low synthesis cost, simple operation, and improvement of conversion rate and intrinsic viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

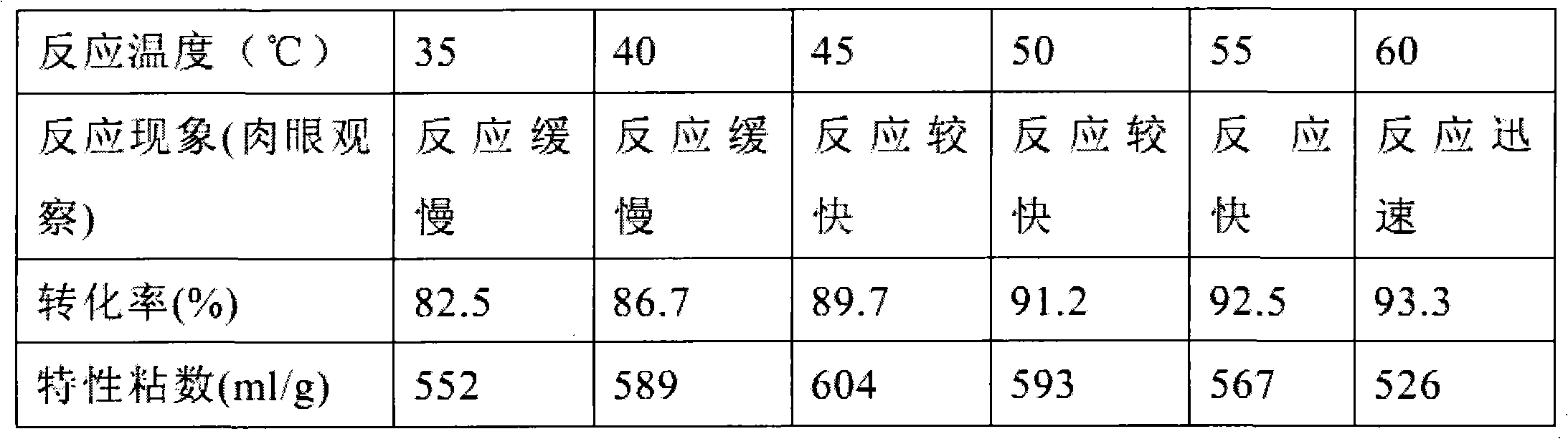

Examples

Embodiment

[0045] The acid liquid thickener synthesis process based on the control reaction system pH value that the present invention relates to, its concrete steps are as follows:

[0046] (a) at first, carry out the purification of reaction monomer;

[0047] (b) preparation of initiator solution;

[0048] (c) according to proportioning, take the 2-methyl-2-acrylamidopropanesulfonic acid solid of certain quality and be dissolved in distilled water;

[0049] (d) adding a certain amount of acrylic acid and dimethyl diallyl ammonium chloride to the solution of step (c), and fully dissolving the three reaction monomers;

[0050] (e) After mixing evenly, adjust the pH value of the solution;

[0051] (f) then move the reaction mixed solution into a constant temperature reaction vessel, exhaust oxygen and stir;

[0052] (g) adding the initiator solution dropwise;

[0053] (h) Finally, under the protection of an inert gas, the reaction system is heated to conduct a polymerization reaction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com