A kind of material and preparation method for making refrigerator door handle

A technology for door handles and refrigerators. It is applied in the field of polymer materials and their molding processing. It can solve the problems of difficult cleaning of the film, achieve excellent mechanical properties, increase the number of door openings, and smooth the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

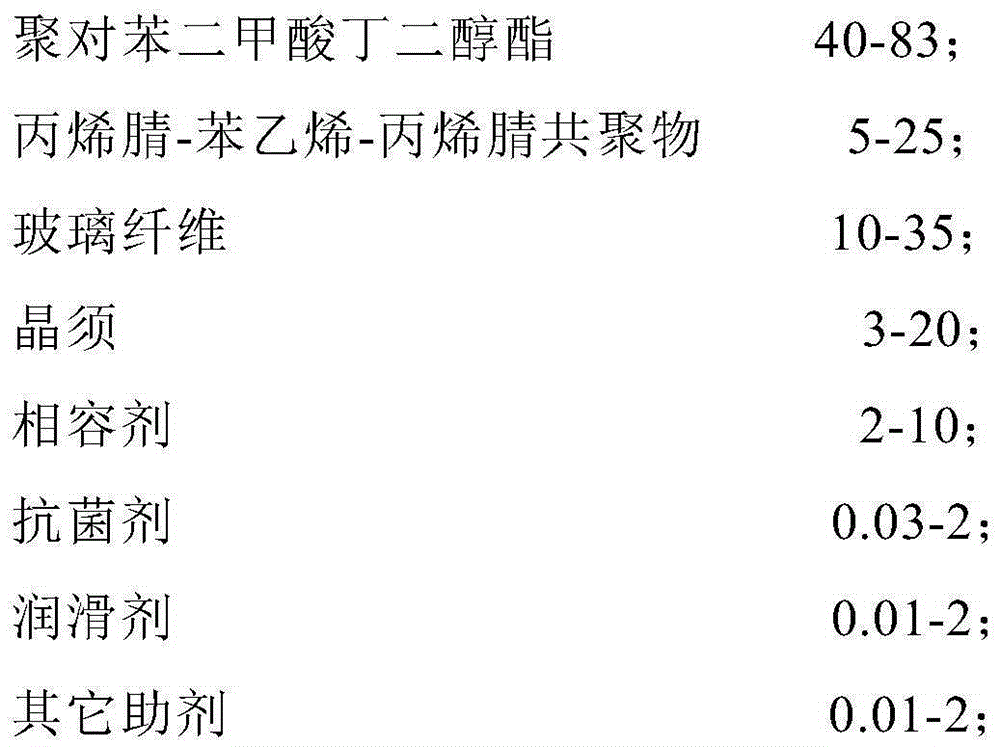

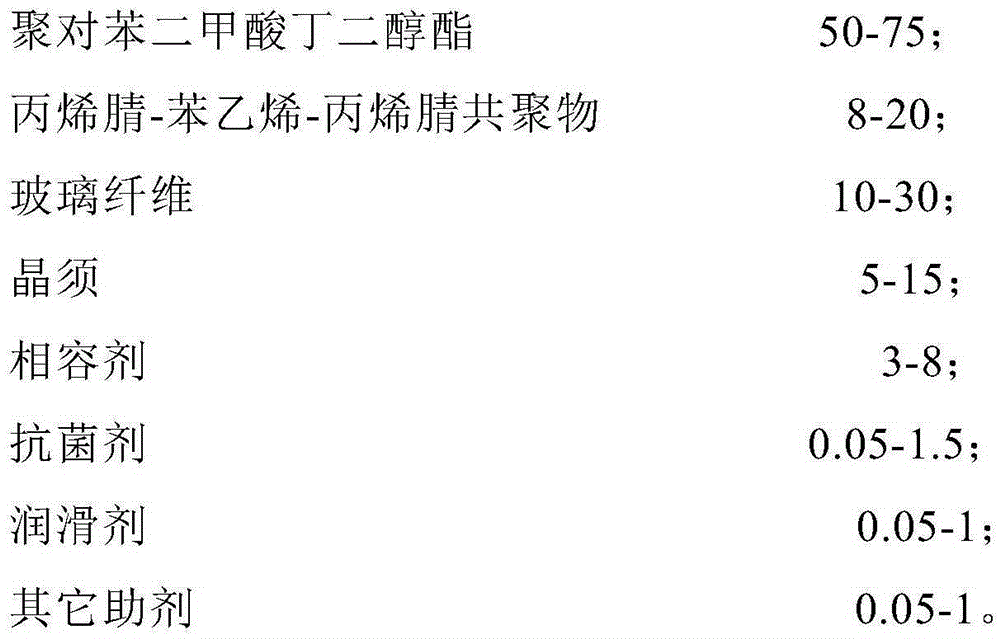

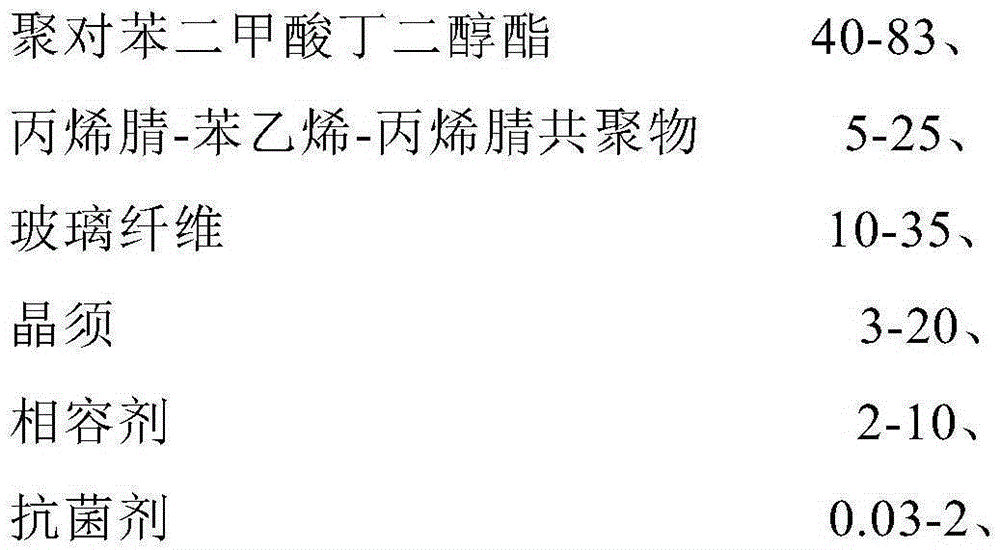

Method used

Image

Examples

Embodiment 1

[0074] First, SiC whiskers that are 3 parts by weight, compatibilizer 1 that are 3 parts by weight, antibacterial agent 1 that are 0.03 parts by weight, lubricant 1 that is 0.01 parts by weight and tetrakis[methyl-β] that are 0.01 parts by weight -(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite in a 1:1 mixture. Place in a temperature-controlled high-speed blender. Stir at high speed at 90°C for 2 minutes, then add 40 parts by weight of polybutylene terephthalate pellets and 5 parts by weight of acrylonitrile-styrene-acrylic acid terpolymer at room temperature and stir for 2 minutes, and finally mix The last component is put into the extruder. During the extrusion process, 35 parts by weight of glass fiber is added from the glass fiber port, mixed at 255-270°C to obtain a polymer, and the obtained polymer is extruded in a strip shape, and then It is cut into segments to form 2-5mm pellets. The obtained pellets we...

Embodiment 2

[0076] First, the SiC whiskers with 20 parts by weight, the compatibilizer 1 with 10 parts by weight, the antibacterial agent 2 with 2 parts by weight, the lubricant 2 with 2 parts by weight and the tetrakis[methyl-β with 2 parts by weight] -(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite in a 1:1 mixture. Place in a temperature-controlled high-speed blender. Stir at high speed at 90°C for 10 minutes, then add 83 parts by weight of polybutylene terephthalate pellets and 25 parts by weight of acrylonitrile-styrene-acrylic acid terpolymer at room temperature and stir for 6 minutes, and finally mix The last component is put into the extruder. During the extrusion process, 10 parts by weight of glass fiber is added from the glass fiber port, mixed at 255-270°C to obtain a polymer, and the obtained polymer is extruded in a strip shape, and then It is cut into segments to form 2-5mm pellets. The obtained pellets were i...

Embodiment 3

[0078] First, SiC whiskers with 5 parts by weight, compatibilizer 1 with 3 parts by weight, antibacterial agent 1 with 0.05 parts by weight, lubricant 1 with 0.05 parts by weight and tetrakis[methyl-β with 0.05 parts by weight] -(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite in a 1:1 mixture. Place in a temperature-controlled high-speed blender. Stir at high speed at 90°C for 5 minutes, then add 50 parts by weight of polybutylene terephthalate pellets and 8 parts by weight of acrylonitrile-styrene-acrylic acid terpolymer at room temperature and stir for 3 minutes, and finally mix The last component is put into the extruder. During the extrusion process, 30 parts by weight of glass fiber is added from the glass fiber port, mixed at 255-270°C to obtain a polymer, and the obtained polymer is extruded in strips, and then It is cut into segments to form 2-5mm pellets. The obtained pellets were injection molded into c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com