Mineral powder calcining dehydration device

A technology of dehydration device and mineral powder, which is applied to heating device, drying solid materials, and preliminary treatment to promote the drying of solid materials, etc. Heat utilization efficiency, precise temperature control, and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

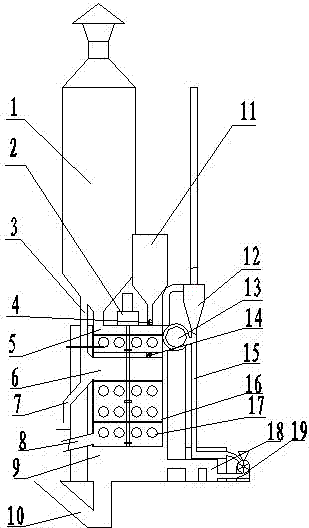

[0011] Such as figure 1 Shown is a specific embodiment of the present invention, the mineral powder calcining dehydration device includes a furnace wall, a pot body 16 is arranged on the inside of the furnace wall, a furnace 9 is arranged below, and a raw material bin 11 and a furnace 9 are arranged on the top of the pot body 16. The steam dedusting device 1, the furnace 9 is connected to the combustion chamber 18 and the combustion equipment 19, and the bottom of the furnace 9 is provided with an ash outlet 10.

[0012] The pot body 16 is composed of a tail preheating chamber 5 and a calcining chamber 6, and a stirring device 2 is installed through the pot body 16 from top to bottom, and the fire tube 17 inside the pot body 16 is vertically and horizontally arranged. A feeding controller 4 is connected between the raw material bin 11 and the tail preh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap