Preparation method of lithium iron phosphate precursor

A lithium iron phosphate and precursor technology is applied in the field of preparation of lithium iron phosphate precursor, which can solve the problem of low amount of LiFePO4, and achieve the effect of improving reaction effect, good commercialization prospect, good high charge-discharge performance and cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

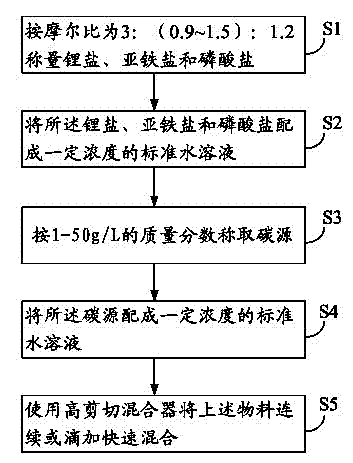

[0020] see figure 1 , which is a flowchart of a method for preparing a lithium iron phosphate precursor according to a preferred embodiment of the present invention. The present invention specifically provides a high-shear method for preparing a lithium iron phosphate precursor, comprising the following steps: weighing lithium salt, ferrous salt and phosphate in a molar ratio of 3: (0.9-1.5): 1.2 (step S1) ; Formulate the lithium salt, ferrous salt and phosphate into a standard aqueous solution of a certain concentration (step S2); weigh the carbon source according to the mass fraction of 1-50g / L (step S3), and formulate the carbon source into A standard aqueous solution of a certain concentration (step S4); using a high-shear mixer to rapidly mix the above materials continuously or dropwise (step S5).

[0021] In a preferred embodiment, the above-mentioned lithium salt is one of lithium hydroxide and lithium phosphate or a mixture of both.

[0022] In a preferred embodiment...

Embodiment approach 1

[0028] Weigh lithium salt, ferrous salt and phosphate according to molar ratio Li: Fe: P = 3: (0.98 ~ 1): 1.2. 79.238g (ie 0.294mol) of FeSO 4 ·7H 2 O was dissolved in water and diluted to 150 mL. Add 35g of glucose to the phosphoric acid solution and dilute to 100mL.

[0029] The above materials were circulated in a high shear continuous mixer to achieve uniform mixing.

[0030] Add the high-shear mixed precursor into the autoclave, and after purging the air in the autoclave with an inert gas, seal the autoclave and react at 140-350°C for 30-600 minutes.

[0031] After the above reaction is completed, quickly cool to 30°C with condensed water, take out the product, filter and wash until there is no sulfate ion; the filter cake is vacuum-dried at 80 ~ 120°C for 12 hours.

[0032] The product obtained in the previous step was calcined at 700°C for 4 hours to obtain 40g LiFePO4 / C product.

Embodiment approach 2

[0034] Weigh lithium salt, ferrous salt and phosphate according to molar ratio Li: Fe: P = 3: (0.98 ~ 1): 1.2. 79.238g (ie 0.294mol) of FeSO 4 ·7H 2 O was dissolved in water and diluted to 150 mL. Add 35g of glucose to the phosphoric acid solution and dilute to 100mL.

[0035] Add the above materials dropwise to a high shear batch mixer and mix rapidly.

[0036] Add the high-shear mixed precursor into the autoclave, and after purging the air in the autoclave with an inert gas, seal the autoclave and react at 140-350°C for 30-600 minutes.

[0037] After the above reaction is completed, quickly cool to 30°C with condensed water, take out the product, filter and wash until there is no sulfate ion; the filter cake is vacuum-dried at 80 ~ 120°C for 12 hours.

[0038] The product obtained in the previous step was calcined at 700°C for 4 hours to obtain 40g LiFePO 4 / C product.

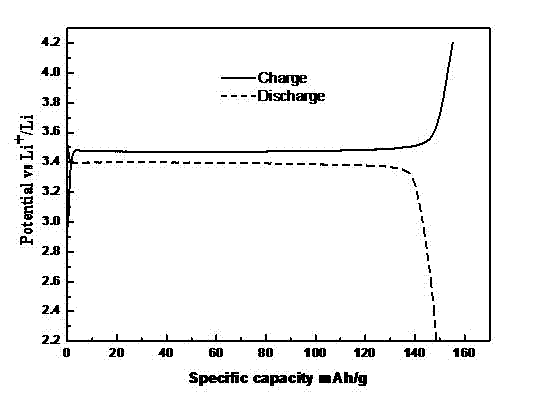

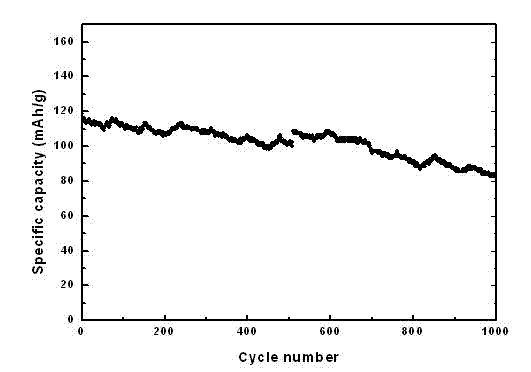

[0039] see Figure 2 to Figure 4 , figure 2 LiFePO which is a preferred embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com