Bacteriostatic peculiar-smell-absorbing crib mattress and manufacturing method thereof

A bed core and odor technology, applied to mattresses, spring mattresses, and other seating furniture, can solve problems such as poor comfort and environmental protection, mattress hardening, and long-worm deterioration, and achieve good hygroscopicity and air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

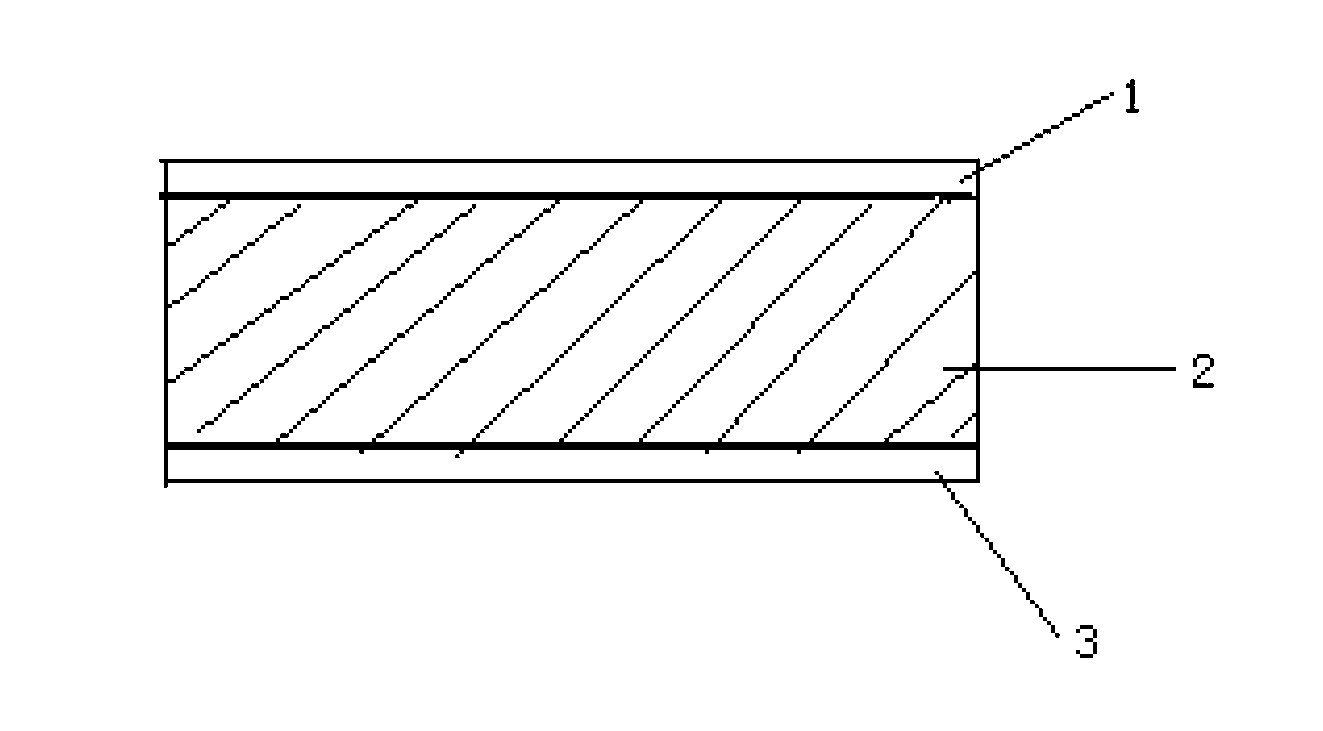

[0033] An antibacterial and odor-absorbing baby bed core, comprising at least one middle layer 2 and a surface layer arranged on the upper or lower surface of the middle layer 2, the surface layer is composed of the following components by weight percentage: 15% PLA fiber, 85% bamboo fiber, the middle layer 2 is composed of the following components by weight percentage: 85% bamboo fiber and 15% PP fiber.

[0034] Its preparation method comprises the following steps:

[0035]In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layers of the upper surface layer 1 and the lower surface layer 3 respectively. The non-woven layer of surface layer 1 and lower surface layer 3 adopts 15% PLA fiber and 85% bamboo fiber, and the acupuncture density in the acupuncture process is 88 punches / cm 2 ;

[0036] In the second step, the middle layer 2 is obtained by weighing, openi...

Embodiment 2

[0051] An antibacterial and odor-absorbing baby bed core, comprising at least one middle layer 2 and a surface layer arranged on the upper or lower surface of the middle layer 2, the surface layer is composed of the following components by weight percentage: 40% PP fiber, 60% bamboo fiber, the middle layer 2 is composed of the following components by weight percentage: 60% bamboo fiber and 40% ES fiber.

[0052] Its preparation method comprises the following steps:

[0053] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layers of the upper surface layer 1 and the lower surface layer 3 respectively. The non-woven layer of surface layer 1 and lower surface layer 3 adopts 40% PP fiber and 60% bamboo fiber, and the acupuncture density in the acupuncture process is 66 punches / cm 2 ;

[0054] In the second step, the middle layer 2 is obtained by weighing, openin...

Embodiment 3

[0068] An antibacterial and odor-absorbing baby bed core, comprising at least one middle layer 2 and a surface layer arranged on the upper or lower surface of the middle layer 2, the surface layer is composed of the following components by weight percentage: 30% of 4080 fiber and 70% bamboo fiber, the middle layer 2 is composed of the following components by weight percentage: 70% bamboo fiber and 30% low melting point fiber.

[0069] Its preparation method comprises the following steps:

[0070] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layers of the upper surface layer 1 and the lower surface layer 3 respectively. The non-woven layer of surface layer 1 and lower surface layer 3 adopts 30% 4080 fiber and 70% bamboo fiber, and the needle punching density in the needle punching process is 44 punches / cm 2 ;

[0071] In the second step, the middle layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com