Device and method for removing terephthalic acid granules from methacrylic acid reaction gas

A technology for terephthalic acid and methacrylic acid, applied in separation methods, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., can solve the problems of reducing the start-up period of the device, damage to the circulating gas compressor, easy blockage of equipment and Pipeline and other problems, to achieve the effect of convenient processing and manufacturing, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

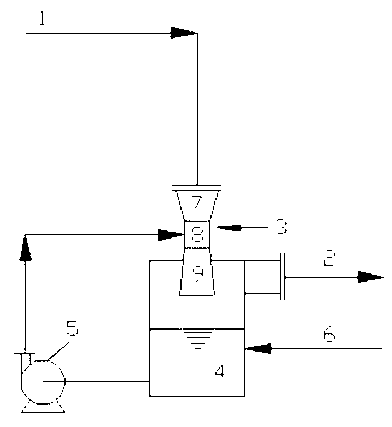

[0051] The generated gas of the oxidation reactor of the 70,000 tons / year methacrylic acid plant is 10,000kg / h, and the content of each component is shown in the table below:

[0052] components wt% oxygen 8.20 Isobutylene 0.00 Nitrogen 62.25 carbon monoxide 1.00 carbon dioxide 5.60 Acetaldehyde 0.20 methacrolein 2.80 tert-butanol 0.00 acrolein 0.15 acetone 0.30 acetic acid 1.50 acrylic acid 0.10 water 11.20 Methacrylate 6.30 Terephthalic acid 0.40

[0053]Among them, the content of terephthalic acid (PTA) is 0.4wt%, and the particles above 1 μm account for 80%. The gas is transported to the device by the DN1100 pipeline, enters the shrinking section of the scrubber, the ratio of the inlet and outlet of the shrinking section is 3:1, and the flow rate in the straight pipe section of the scrubber reaches 60m / s, and then enters the expanding section. The import and export rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com