Manufacturing and application methods for laser cladding powder of iron-base alloy

A technology of laser cladding and manufacturing methods, which is applied in the direction of metal material coating process and coating, can solve the problems of decreased fatigue strength of the cladding layer, can not completely prevent cracks, micro and macro cracks, etc., and achieve low residual stress, High fatigue strength and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

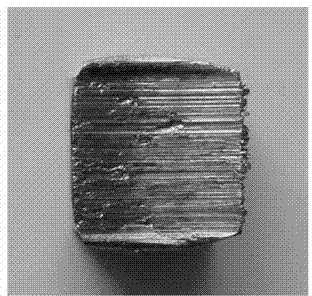

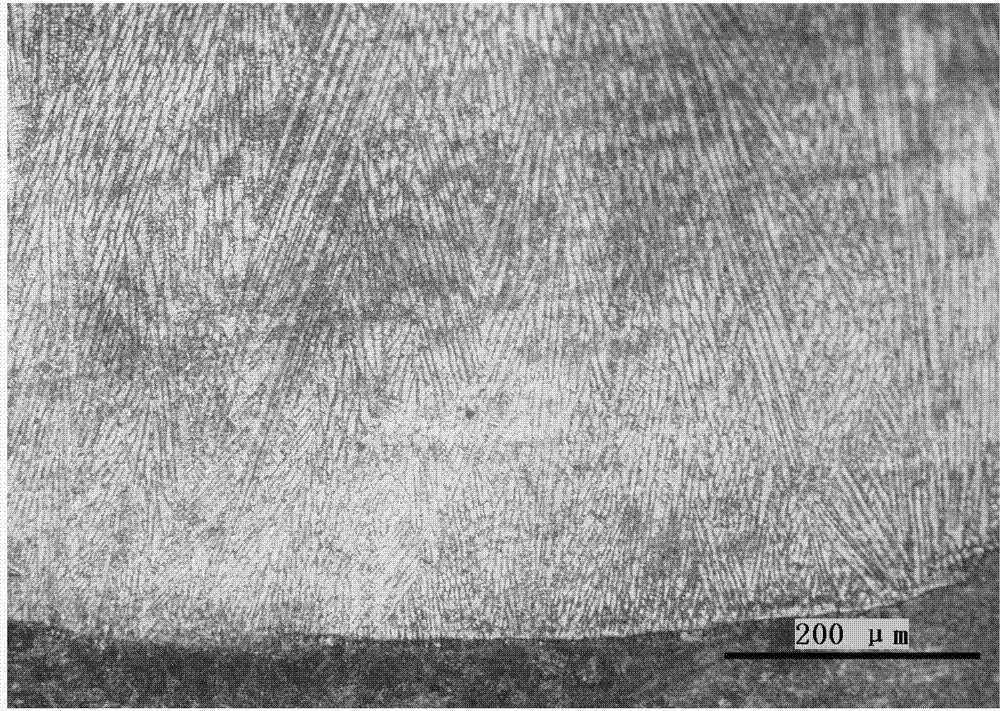

[0037] The present invention and its beneficial effects will be further described below in conjunction with the accompanying drawings and embodiments. Since the present invention uses Fe-Mn-Si memory alloy powder as laser cladding powder, the mechanism of Fe-Mn-Si memory alloy cladding layer to reduce weld residual stress is that the residual tensile stress of the cladding layer can induce the alloy to induce γ→ ε martensitic phase transformation, whose phase transformation deformation (expansion) will relax the residual tensile stress of the cladding layer and reduce it below the yield strength (because the induced phase transformation driving force is lower than the yield strength); Fe-Mn- The method of improving the fatigue strength of the Si memory alloy cladding layer is based on its "stress adaptive characteristics", that is, when the alloy is subjected to external stress, it can induce the positive and negative phase transformation of ε martensite and the phase transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com