Electrolytic squeezing device applied to dehydrator or deoiling machine

A deoiler and dehydrator technology, applied in the direction of dehydration/drying/concentrated sludge treatment, can solve the problems of mechanical and electrical structure complexity, high heating cost, increased failure rate, etc. Discharge and short-circuit accidents, the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

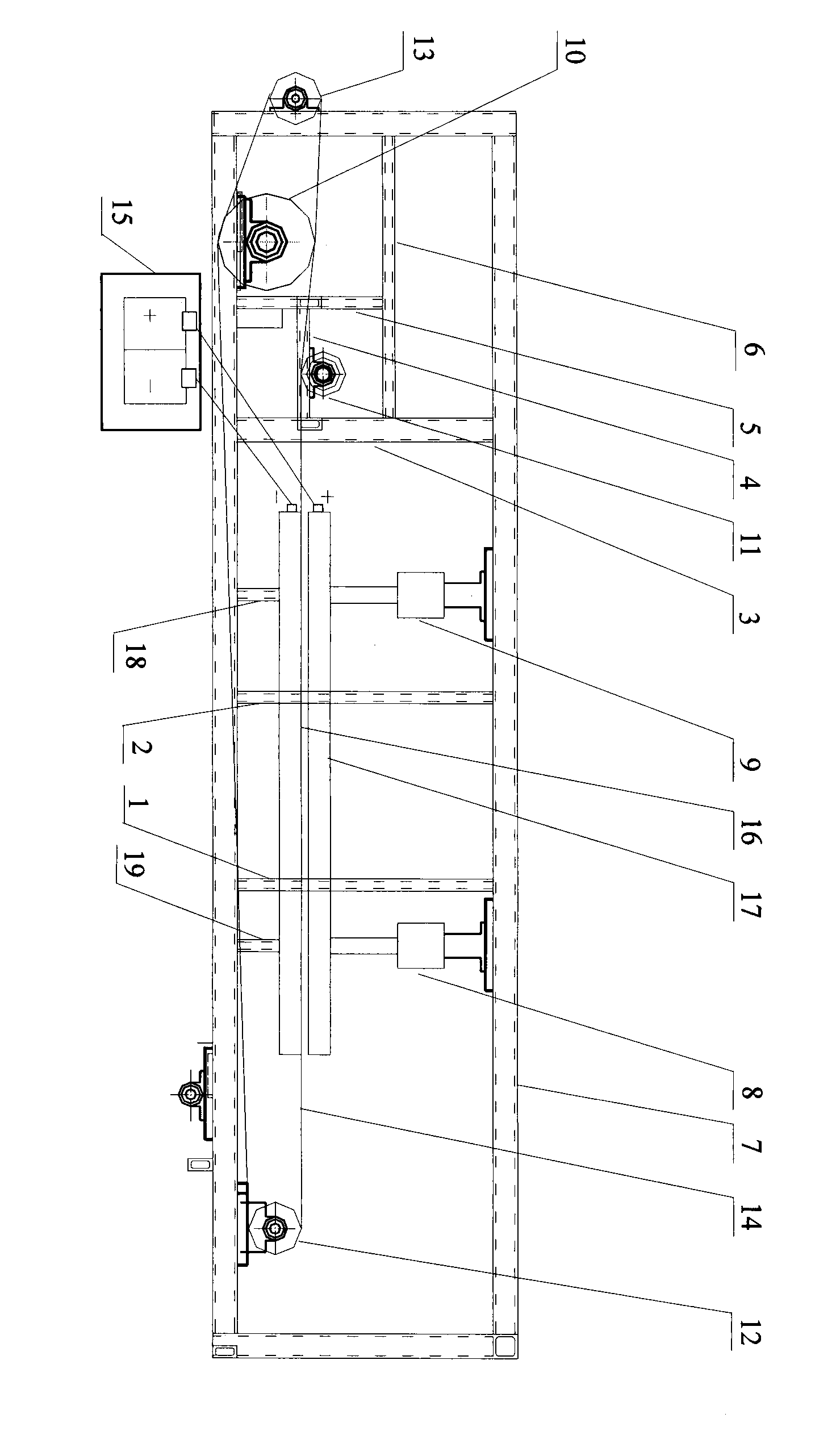

[0015] The drawings include an upper platen 17, a lower platen 16, an external DC power supply 15, an annular filter cloth 14, a filter cloth front roller 13, a filter cloth rear roller 12, a material winding roller 11, a filter cloth driving device 10, an upper Platen driving equipment A9, upper platen driving equipment B8, horizontal frame 7, frame support A6, frame support B5, frame support C4, frame support D3, frame support E2, frame support F1, lower platen front support 18, lower platen rear support 19.

[0016] The horizontal frame 7 provides the supporting function of the overall structure. The frame support A6 is used as the inlet of the sludge material at the same time. Support, the frame support E2 and the frame support F1 enhance the strength of the horizontal frame 7 .

[0017] The upper platen drive device A9 and the upper platen drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com