Modified cement blending material and concrete used for grouting wall and prepared by the same

A kind of mixing material and cement technology, applied in the field of modified cement mixing material, can solve the problems of poor concrete work performance, concrete segregation, easy floating of polyphenylene particles, etc., achieve good economic and social benefits, facilitate pouring construction, The effect of excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

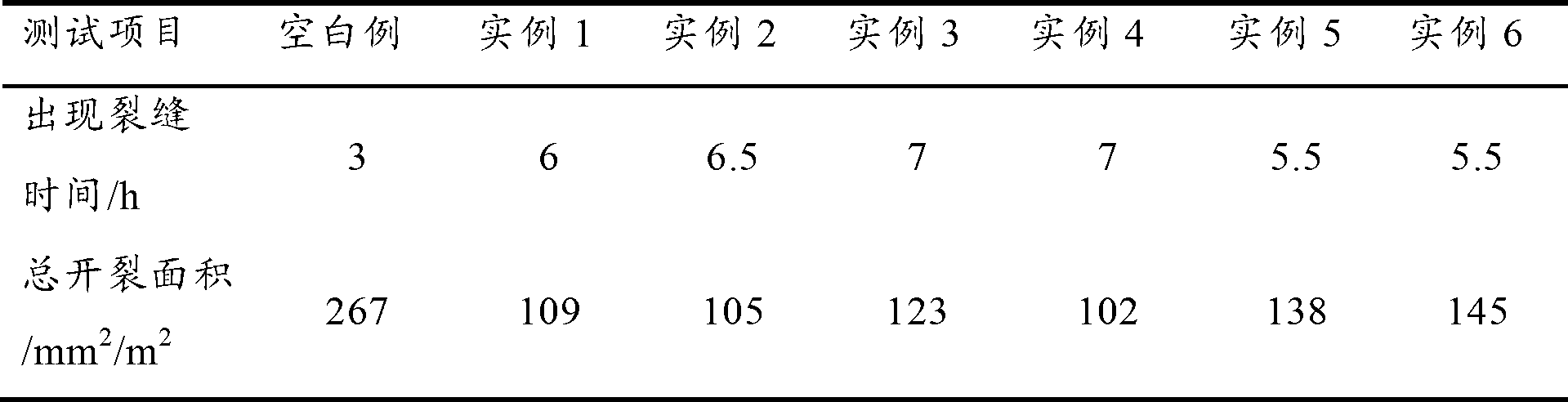

Examples

Embodiment 1

[0042] 275kg of 425# ordinary Portland cement, 100kg of secondary fly ash, 125kg of river sand, 5kg of polypropylene fiber, 3kg of redispersible rubber powder, 3kg of cellulose ether and 4kg of polycarboxylate Put the water agent into the concrete mixer and stir for 1-2 minutes to make the materials evenly mixed. Then add 200kg of water and stir for 1-2 minutes. After making mortar, add 13.5kg of polystyrene particles and stir evenly to obtain the finished product L 1 .

Embodiment 2

[0044]350kg of 425# ordinary Portland cement, 100kg of secondary fly ash, 175kg of river sand, 5kg of polypropylene fiber, 3kg of redispersible rubber powder, 3kg of cellulose ether and 4kg of polycarboxylate Put the water agent into the concrete mixer and stir for 1-2 minutes to make the materials evenly mixed. Then add 260kg of water and stir for 1-2 minutes. After making mortar, add 12kg of polystyrene particles and stir evenly to obtain the finished product L 2 .

Embodiment 3

[0046] 380kg of 425# ordinary Portland cement, 144kg of secondary fly ash, 180kg of river sand, 5kg of polypropylene fiber, 3kg of redispersible rubber powder, 3.6kg of cellulose ether and 4kg of polycarboxylic acid Put the water reducing agent into the concrete mixer and stir for 1-2 minutes to make the materials evenly mixed. Then add 220kg of water and stir for 1-2 minutes. After making mortar, add 11.3kg of polystyrene particles and stir evenly to obtain the finished product L 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com