Method for preparing amino acid liquid fertilizer by hydrolyzing animal proteins with multiple acids and application of amino acid liquid fertilizer

A technology for animal protein and liquid fertilizer, applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problem of low content of amino acid components in fertilizer, and achieve the effect of reducing production cost, reducing nitrogen loss, and good coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

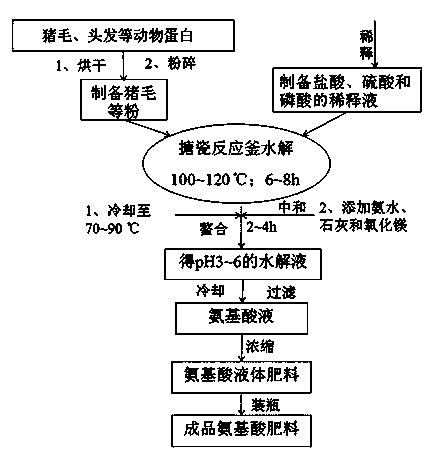

[0035] For the specific steps of this embodiment, see figure 1 .

[0036] (1) Pretreatment of animal protein: After cleaning up impurities such as plastic, wood and metal in the discarded pig hair, expose it to the sun for 2 days, and then dry it with a drying blower at 60°C for 6 hours. The hair pulverizer is prepared into pig hair powder, which can be used as raw material for the preparation of amino acid liquid fertilizer

[0037] (2) Acid hydrolysis: according to the content of each component specified in the following table 1, add the mass percent concentration of 25% hydrochloric acid, 30% phosphoric acid, and 20% sulfuric acid into the reaction kettle and step (1) in sequence according to the mass ratio Mix pig hair powder, the mass ratio of pig hair powder to hydrochloric acid, phosphoric acid and sulfuric acid is 1:2; heat to 80°C, control the temperature to 110°C after 2h, and acidolysis time is 7h to obtain acidolysis solution

[0038] (3) Neutralization: After t...

Embodiment 2

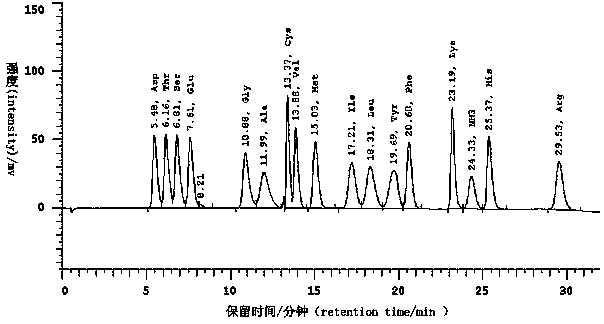

[0042] Repeat the method of Example 1 according to the content of each component specified in the following table 1, the obtained amino acid liquid fertilizer is as follows figure 2 Shown in VIII.

Embodiment 3

[0044] Repeat the method of Example 1 according to the content of each component specified in the following table 1, the obtained amino acid liquid fertilizer is as follows figure 2 Shown in IX.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com