System for producing ethyl butyrate continuously

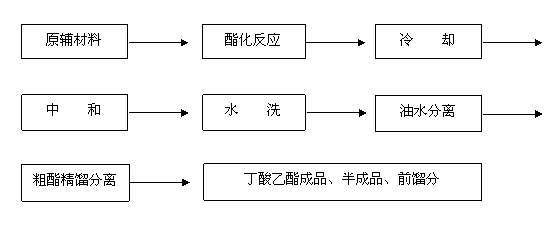

A technology for the production of ethyl butyrate and a feeding system, which is applied in the preparation of carboxylate, the preparation of organic compounds, organic chemistry, etc., can solve the problems of many by-products, equipment corrosion, and low efficiency, and achieve continuous production, Easy separation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

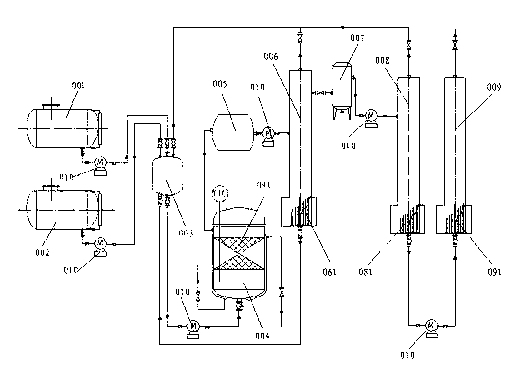

[0022] Embodiment 1: as figure 2 As shown, 3500 kg of strongly acidic resin is filled in the reactor 004 as a catalyst. Before starting the continuous feeding and discharging reaction, the reactor 004 with a capacity of 5 cubic meters is filled with the raw materials butyric acid and ethanol in an equimolar ratio, and the reactor The temperature of 004 is controlled at 75°C. When the reaction reaches the equilibrium conversion rate (esterification rate is about 45%), then restart the feed metering pump 010. At this time, the feed rate of butyric acid is 384 kg / h, and the feed rate of ethanol is The feed rate is 200 kg / h. After the fresh raw materials are mixed by the mixer 003, they are continuously fed into the reactor 004 from the lower inlet of the reactor 004. At the same time, the crude product is continuously discharged from the upper outlet of the reactor 004, and the outlet is at normal pressure. , now the discharge rate is 584 kg / h, which is equivalent to the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com