Preparation method of styrene-N-phenylmaleimide copolymer

A maleimide copolymer and maleimide technology are applied in the field of preparation of styrene-N-phenylmaleimide copolymers, and can solve the problems of poor polymerization degree, complicated steps, low molecular weight, etc. problem, to achieve the effect of saving time, increasing content, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

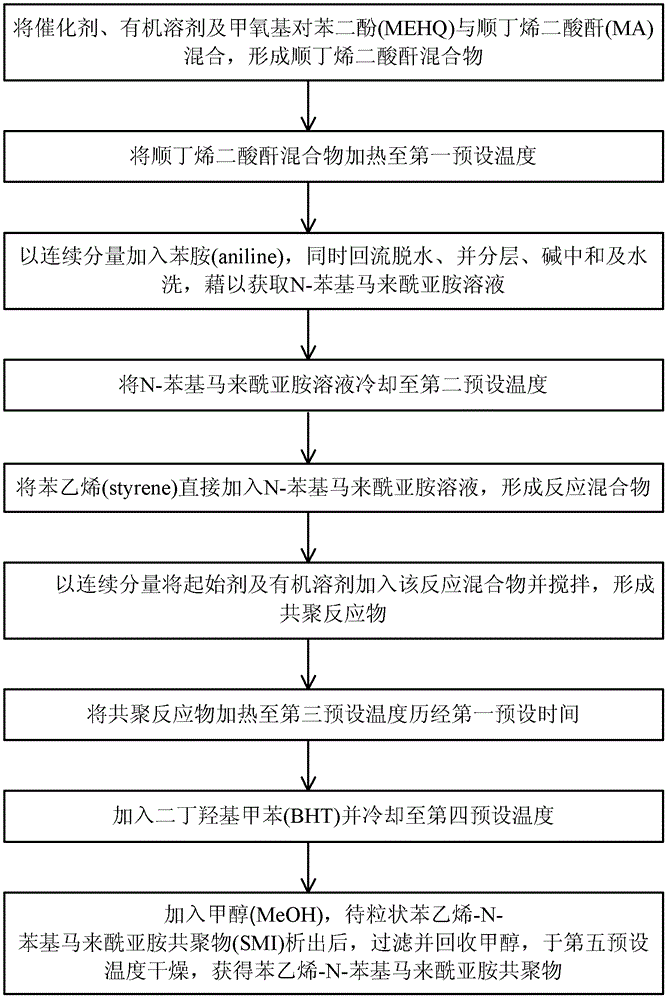

Method used

Image

Examples

Embodiment

[0023] In the reactor, add 500 milliliters (ml) of methyl isobutyl ketone, 103 grams (g) of maleic anhydride, 5 grams (g) of p-toluenesulfonic acid, 20 grams ( g) Dimethylformamide and 0.5 grams (g) of methoxyhydroquinone, heated at 100°C to 120°C to completely dissolve the powder, forming a maleic anhydride mixture; Gradually add 93 grams (g) of aniline to the heat-treated maleic anhydride mixture in one hour and reflux dehydration at the same time. After standing for 10 minutes to separate the layers, add 250 milliliters (ml) of water and 10% to the oil layer. After 20% sodium hydroxide (NaOH) is neutralized at 50°C to 60°C, stir for 10 to 30 minutes, and after standing to separate layers, add 250 milliliters (ml) of water to the oil layer and wash it to obtain N-phenylmethane imide solution.

[0024]After cooling the N-phenylmaleimide solution to 50°C to 80°C, under nitrogen, directly add 100 grams (g) of styrene to the N-phenylmaleimide solution to form a reaction mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com