Preparation and Application of Insulating Cross-linked Polyethylene Composition for Magnetic Suspension Feeder Cable

A technology of cross-linked polyethylene and feeder cables, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve dielectric loss and large dielectric constant, increase the hidden danger of cross-linking material pre-crosslinking, and reduce the service life of cables Shortening and other issues, to achieve the effect of low equipment energy consumption, reduce the hidden danger of pre-crosslinking, and reduce the processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

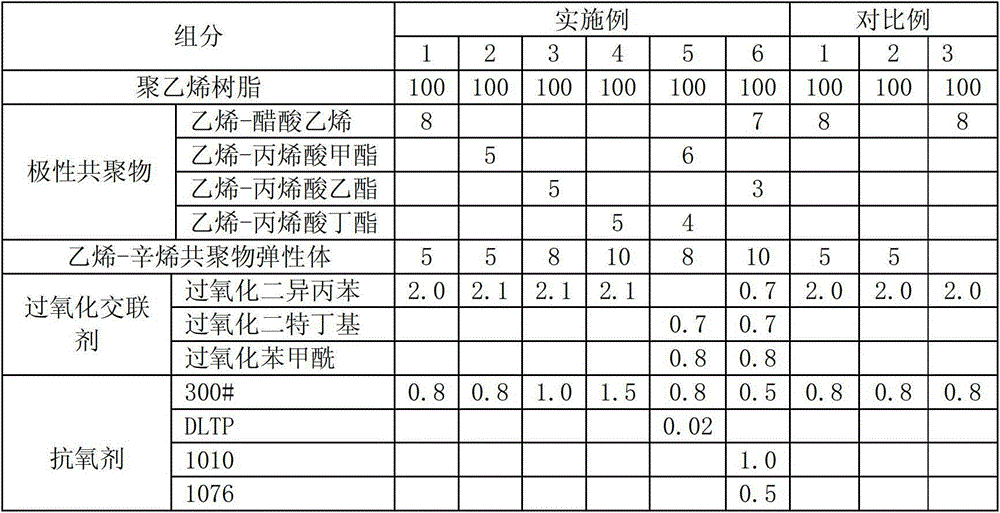

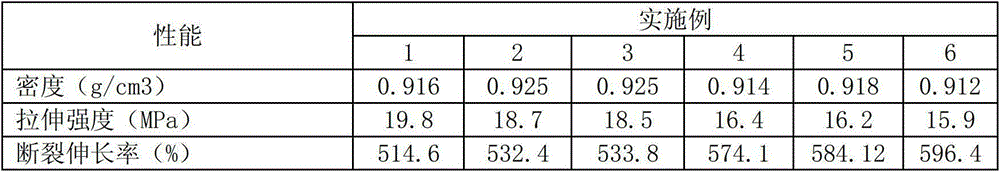

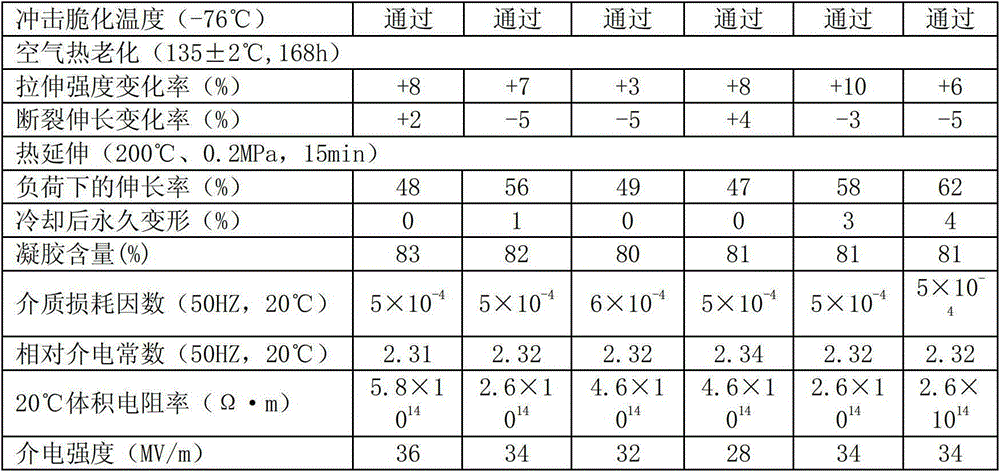

[0026] The components and parts by weight of the insulating crosslinkable polyethylene composition for maglev feeder cables in this embodiment are shown in Table 1, and its preparation method includes the following process steps:

[0027] The raw materials are transported to each silo, using a high-precision loss-in-weight feeding system, and enter the reciprocating single-screw extruder and the single-screw extruder. Cutting, plasticizing, extruding in a single-screw extruder, and then granulating with spray granulation, cooling, centrifugal dehydration, boiling drying, and automatic packaging by an automatic weighing and packaging system to obtain the composition product.

Embodiment 2

[0029] The components and parts by weight of the insulating crosslinkable polyethylene composition for maglev feeder cables in this embodiment are shown in Table 1, and its preparation method includes the following process steps:

[0030] The raw materials are transported to each silo, using a high-precision loss-in-weight feeding system, and enter the reciprocating single-screw extruder and the single-screw extruder. Cutting, plasticizing, extruding in a single-screw extruder, and then granulating with spray granulation, cooling, centrifugal dehydration, boiling drying, and automatic packaging by an automatic weighing and packaging system to obtain the composition product.

Embodiment 3

[0032] The components and parts by weight of the insulating crosslinkable polyethylene composition for maglev feeder cables in this embodiment are shown in Table 1, and its preparation method includes the following process steps:

[0033] The raw materials are transported to each silo, using a high-precision loss-in-weight feeding system, and enter the reciprocating single-screw extruder and the single-screw extruder. Cutting, plasticizing, extruding in a single-screw extruder, and then granulating with spray granulation, cooling, centrifugal dehydration, boiling drying, and automatic packaging by an automatic weighing and packaging system to obtain the composition product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com