Pressure-sensitive adhesive tape for heat dissipation and preparation method thereof

A pressure-sensitive tape and conductive adhesive technology, applied in adhesives, film/sheet adhesives, cooling/ventilation/heating transformation, etc. It is difficult to apply to specific use occasions and other problems to achieve the effect of improving antistatic effect, good antistatic performance and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

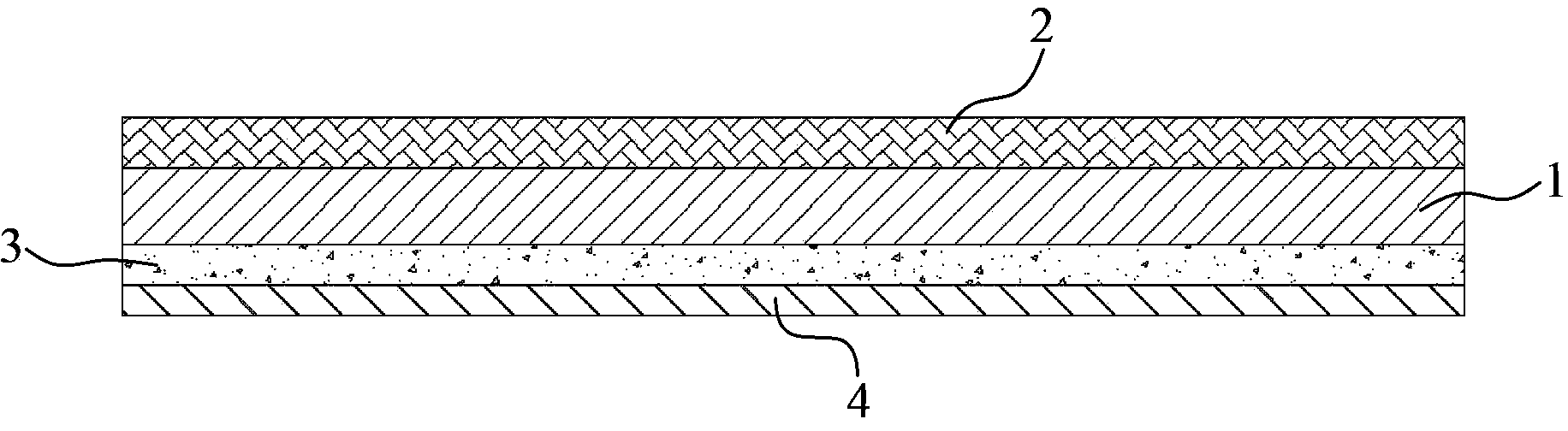

[0062] Embodiment: a kind of pressure-sensitive adhesive tape for heat dissipation, comprising a thickness of 0.004mm ~ 0.025mmPET film, the upper surface of the PET film is coated with an aluminum foil layer, the lower surface of the PET film is coated with a thermally conductive adhesive layer, an isolation The paper is pasted on the other surface of the thermally conductive adhesive layer, and the thermally conductive adhesive layer is composed of the following components by weight:

[0063] Graphite powder 50~150,

[0064] Silicone 50~150,

[0065] Cross-linking agent 0.1~0.5,

[0066] Multifunctional acrylate monomer 10~100,

[0067] Initiator 0.1~1,

[0068] Solvent 50~300;

[0069] The organosilicon is an alkyl silanol conforming to the general formula (1),

[0070] (1);

[0071] In the formula, R represents an alkyl group with 3 to 8 carbon atoms, and n is greater than or equal to 1;

[0072] The crosslinking agent is selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com