High-heat conductivity coefficient graphite heat-radiation adhesive tape

A technology of high thermal conductivity and thermally conductive adhesive, applied in the direction of adhesives, film/sheet adhesives, non-metallic elements, etc., can solve the problems of increasing the thermal conductivity of graphite heat sinks, limiting the application range of graphite heat sinks, and limited functions. Achieve the effects of reducing the probability of graphite cracking, facilitating graphite cutting, and improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

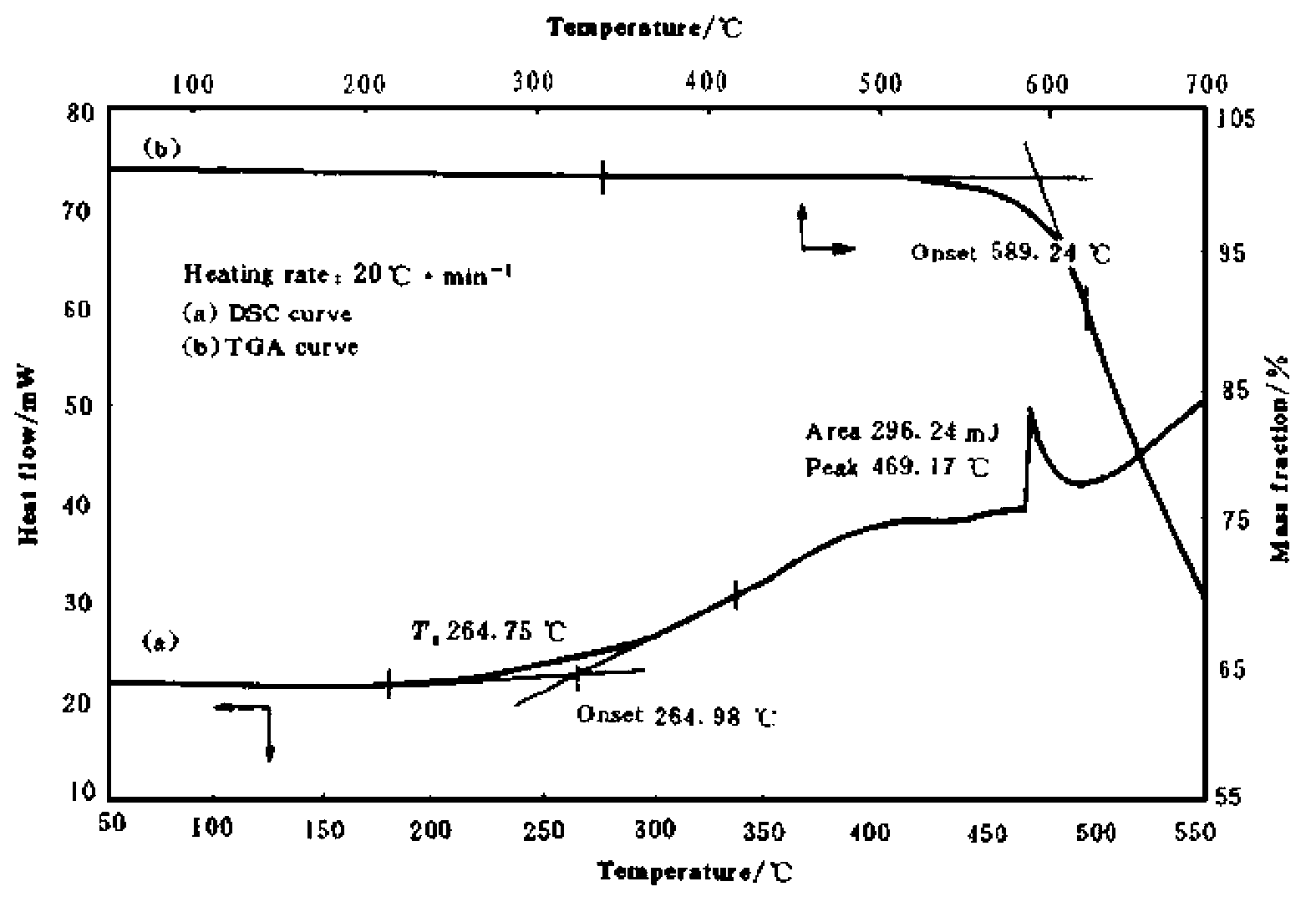

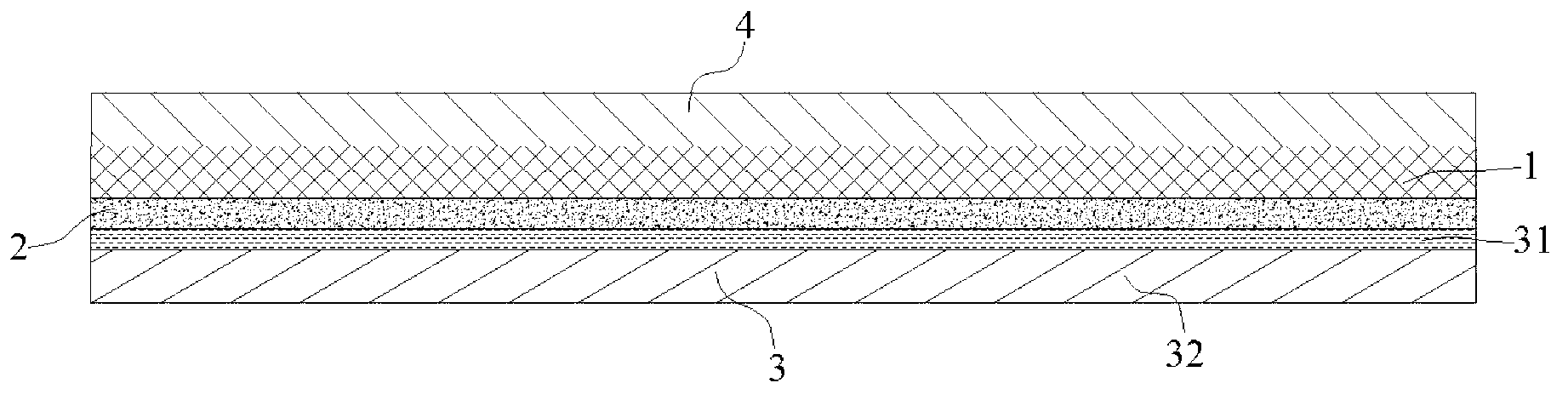

[0032] Embodiment 1: A graphite thermal tape with high thermal conductivity comprises a graphite layer 1, the upper surface of the graphite layer 1 is covered with a metal layer 4, the lower surface of the graphite layer 1 is coated with a thermally conductive adhesive layer 2, and a The molded film 3 is attached to the other surface of the thermally conductive adhesive layer 2; the graphite layer 4 is obtained through the following process, which process includes the following steps:

[0033] Step 1. Add triethylamine to the polyamic acid solution, stir well and apply it on the organic substrate layer;

[0034] Step 2, under the protection of nitrogen, keep the temperature at 80°C for 0.95 hours;

[0035] Step 3, place in an oven in a vacuum environment, keep the temperature at 100°C for 1.05 hours, then raise the temperature to 300°C, keep the temperature at 0.9 hours and then cool naturally, so as to obtain a polyimide film;

[0036] Step 4. Under the protection of inert g...

Embodiment 2

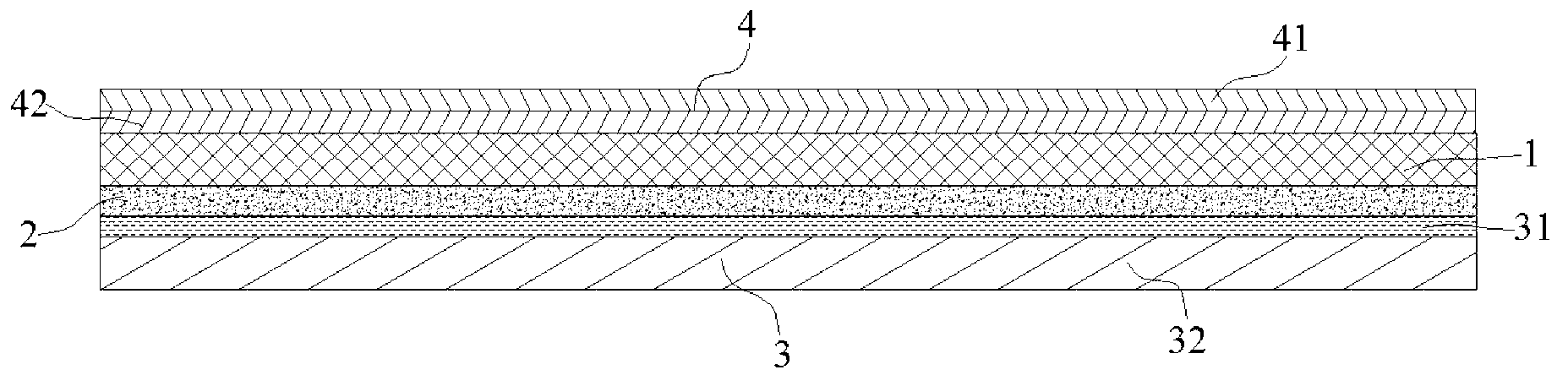

[0041] Embodiment 2: a graphite thermal tape with high thermal conductivity, comprising a graphite layer 1, the upper surface of the graphite layer 1 is covered with a metal layer 4, the lower surface of the graphite layer 1 is coated with a thermally conductive adhesive layer 2, a The molded film 3 is pasted on the other surface of the thermally conductive adhesive layer 2; the metal layer 4 is composed of an aluminum layer 41 and a copper layer 42 laminated, and the copper layer 42 is located between the aluminum layer 41 and the graphite layer 1;

[0042] The graphite layer 4 is obtained by the following process, which comprises the following steps:

[0043] Step 1. Add ethylene glycol to the polyamic acid solution, stir well and apply it on the glass substrate layer;

[0044] Step 2, under the protection of nitrogen, keep the temperature at 80°C for 1 hour;

[0045] Step 3, place in an oven in a vacuum environment, keep the temperature at 100°C for 1 hour, then raise the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com