Oxyfluoride silicate upconversion luminous fluorescent powder, preparation method and application thereof

A technology of fluorooxysilicate and oxysilicate is applied in the field of fluorescent powder to achieve the effects of low cost, low energy consumption and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

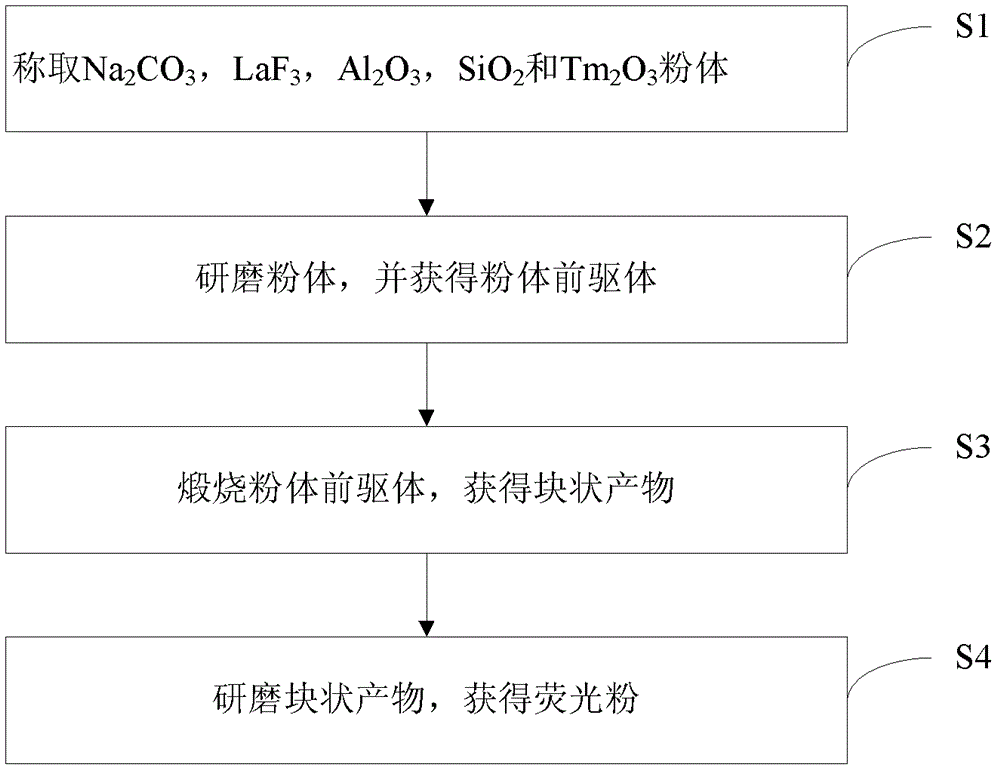

[0023] The preparation method of the above-mentioned oxyfluorosilicate up-converting luminescent phosphor, such as figure 1 shown, including the following steps:

[0024] Step S1, according to the mole percentage, weigh the powder: Na 2 CO 3 , 8~13%; LaF 3 , 6~11.5%; Al 2 o 3 , 25-32%; SiO 2 , 48~53%; Tm 2 o 3 , 0.5~3%;

[0025] Step S2, mixing and grinding the powder weighed in step S1 for 20-60 minutes to obtain a powder precursor;

[0026] Step S3, calcining the powder precursor in step S2 at 900-1400°C for 0.5-5 hours, then cooling down to 600-800°C, keeping it at this temperature for 0.5-3 hours and then cooling to room temperature to obtain a block product ;

[0027] Step S4, grinding the bulk product in step S3 to obtain the fluorescent powder of the oxyfluorosilicate upconversion luminescence; the structural formula of the fluorescent powder is aNa 2 O 3 -cAl 2 o 3 -dSiO 2 :eTm 3+ ; Among them, Tm 3+ are dopant ions, a, b, c, d, e are molar coefficient...

Embodiment 1

[0036] 1. Use powder with a purity of 99.99%: Na 2 CO 3 , LaF 3 , Al 2 o 3 , SiO 2 and Tm 2 o 3 Powder, its molar percentages are 11%, 9%, 29%, 50% and 1% respectively;

[0037] 2. Put the above powder in a corundum mortar and grind it for 40 minutes to mix it evenly to obtain a powder precursor;

[0038]3. Put the powder precursor in a muffle furnace, burn it at 1200°C for 3 hours, then cool it to 700°C and keep it for 2 hours, then cool it naturally to room temperature and take out the block product.

[0039] 4. Grind and pulverize the blocky product to obtain a structural formula of 0.11Na 2 O-0.09LaF 3 -0.29Al 2 o 3 -0.5SiO2 2 :0.01Tm 3+ Up-converting phosphors.

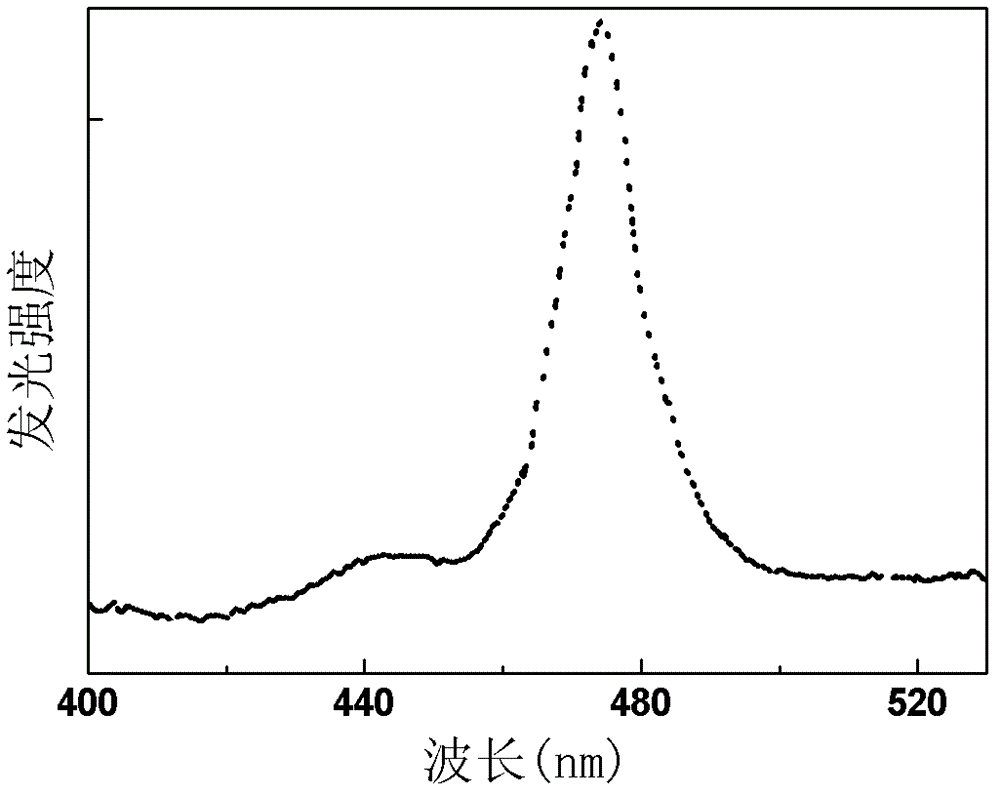

[0040] figure 2 It is the electroluminescence spectrogram of the fluorescent powder of the oxyfluorosilicate up-conversion luminescence that embodiment 1 makes; figure 2 As shown, the excitation wavelength is 796nm; among them, the luminescence peak at 475nm corresponds to Tm 3+ ion 1 G 4 → ...

Embodiment 2

[0042] 1. Use powder with a purity of 99.99%: Na 2 CO 3 , LaF 3 , Al 2 o 3 , SiO 2 and Tm 2 o 3 Powder, its molar percentages are 8%, 11.5%, 32%, 48% and 0.5% respectively;

[0043] 2. Put the above powder in a corundum mortar and grind it for 20 minutes to mix it evenly to obtain a powder precursor;

[0044] 3. Put the powder precursor in a muffle furnace, burn it at 900°C for 5 hours, then cool it to 600°C and keep it for 3 hours, then cool it naturally to room temperature to take out the block product;

[0045] 4. Grind and pulverize the blocky product to obtain a structural formula of 0.08Na 2 O-0.115LaF 3 -0.32Al 2 o 3 -0.48SiO 2 :0.005Tm 3+ Up-converting phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com