Dust cleaning system applicable to heat recovery boiler with complex heating surface

A waste heat boiler and heating surface technology, which is used in the removal of solid residues, lighting and heating equipment, combustion products treatment, etc., can solve problems such as difficulty in using waste heat boilers, unsuitable recovery of granular materials, and poor airtightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

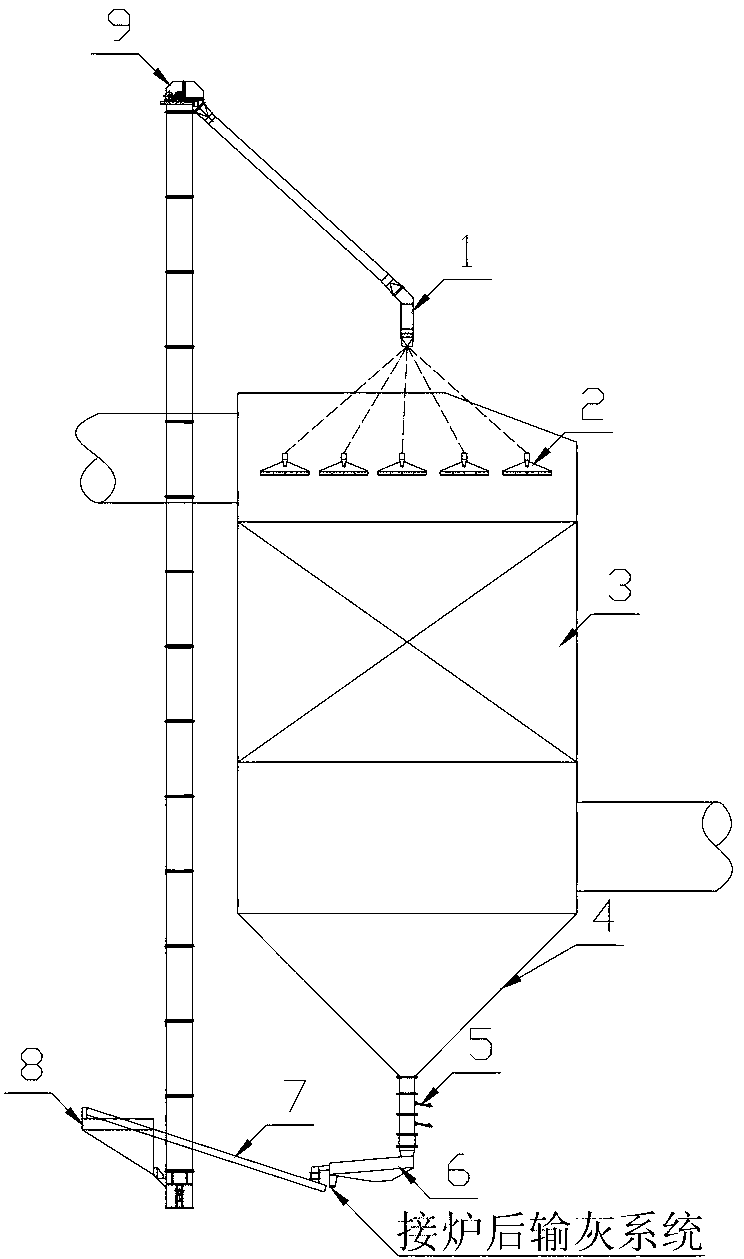

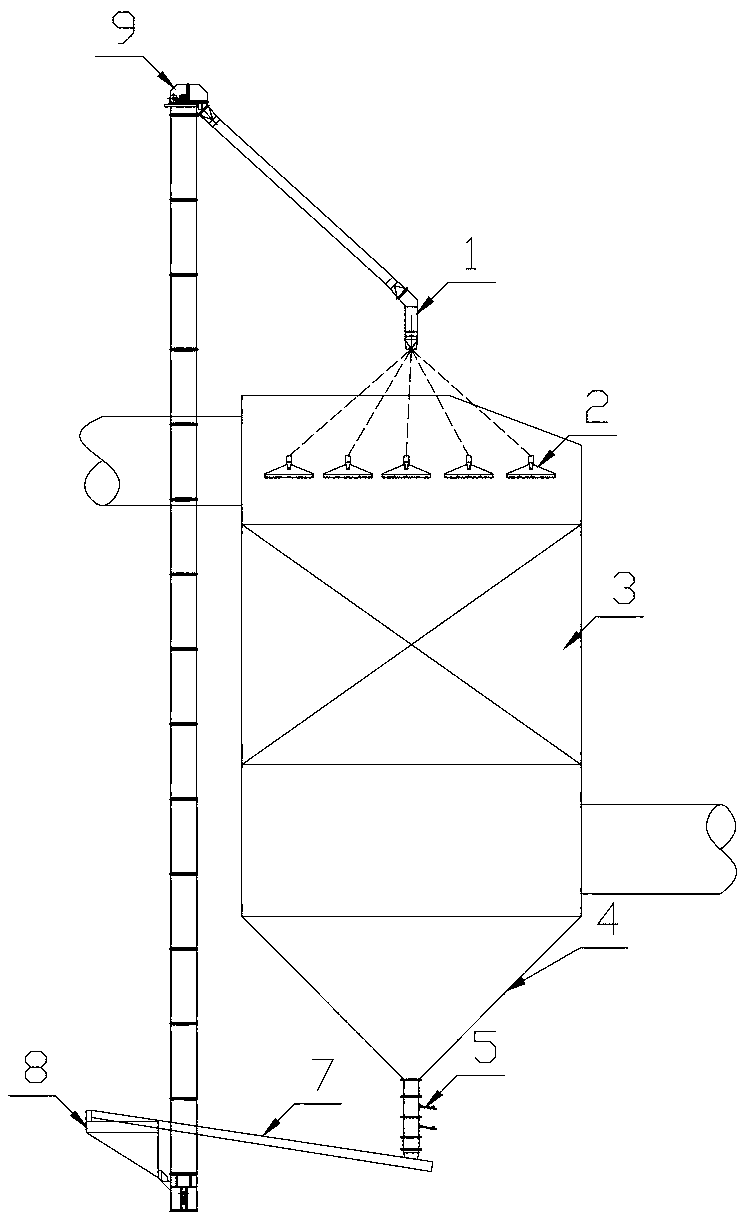

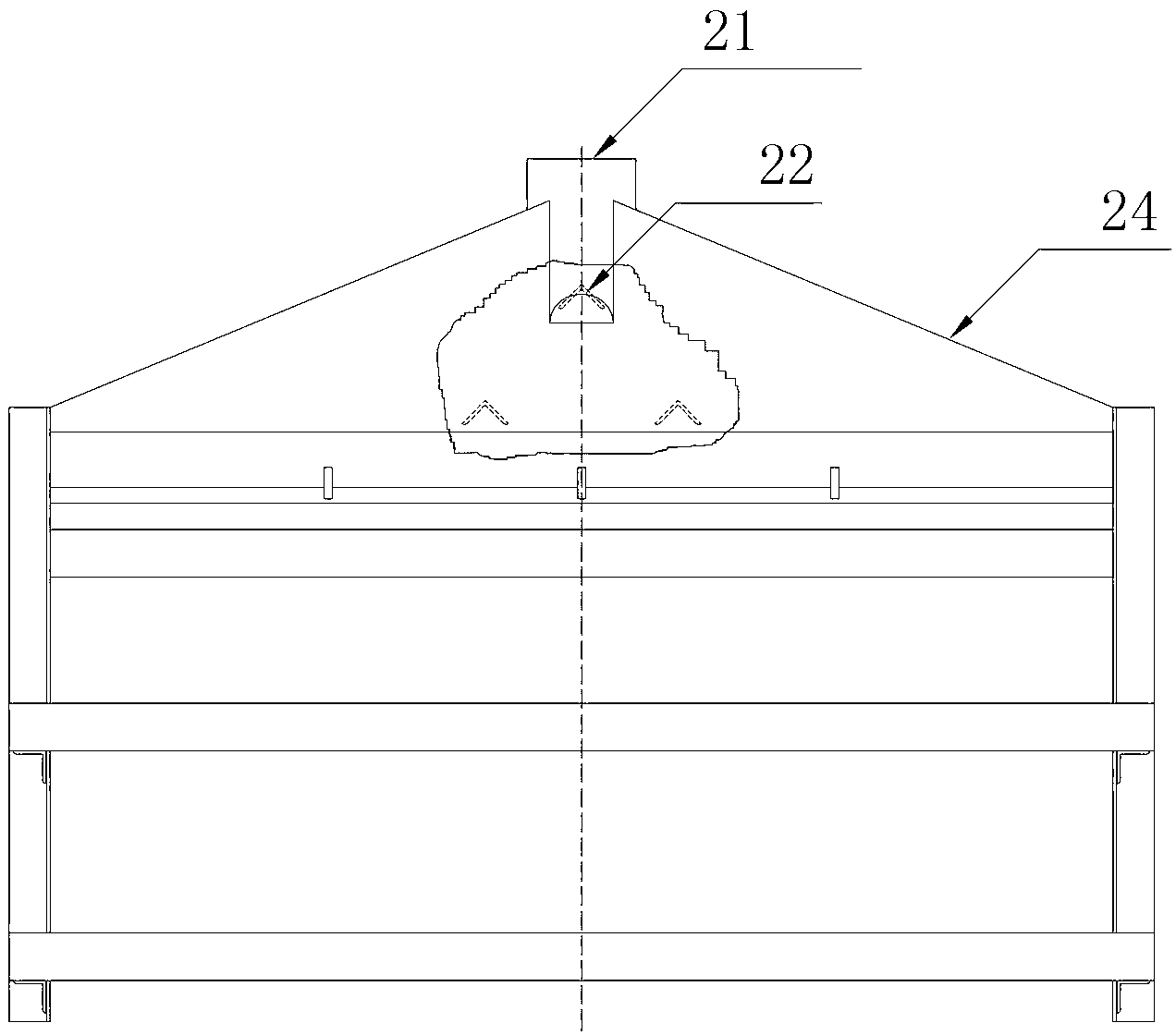

[0023] like Figure 1 to Figure 5 As shown, the present invention relates to a ash cleaning method or system suitable for a waste heat boiler with a complex heating surface, and the purpose is to develop a waste heat boiler with a complex heating surface such as fins / fins / annular fin tubes that can adapt to 24-hour operation. The ash cleaning system, through reasonable and efficient shot distribution device, shot collection system, screening system, and transportation and lifting system, can obtain a heating surface cleaning system or device with more stable and reliable operation, lower investment and better cleaning effect, It is planned to replace the conventional ash cleaning device in some flue gas waste heat recovery occasions.

[0024] The present invention is a waste heat boiler cleaning method system suitable for complex heating surfaces, including a pelletizing device 1, a pellet distributor 2, a waste heat boiler 3, a pellet collecting hopper 4, a flap valve 5, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com