Heat or flow management system used for passive type direct methanol fuel cell

A methanol fuel cell, passive technology, applied to fuel cell parts, fuel cells, fuel cell additives, etc., can solve the problems of two-phase mass transfer at the two poles of the battery, limit the performance of DMFC, and low utilization of methanol, etc., to improve Effects of energy utilization, increase in mass transfer resistance and heat transfer rate, and increase in fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] In order to further understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but it should be noted that the protection scope of the present invention is not limited to the scope expressed in the examples.

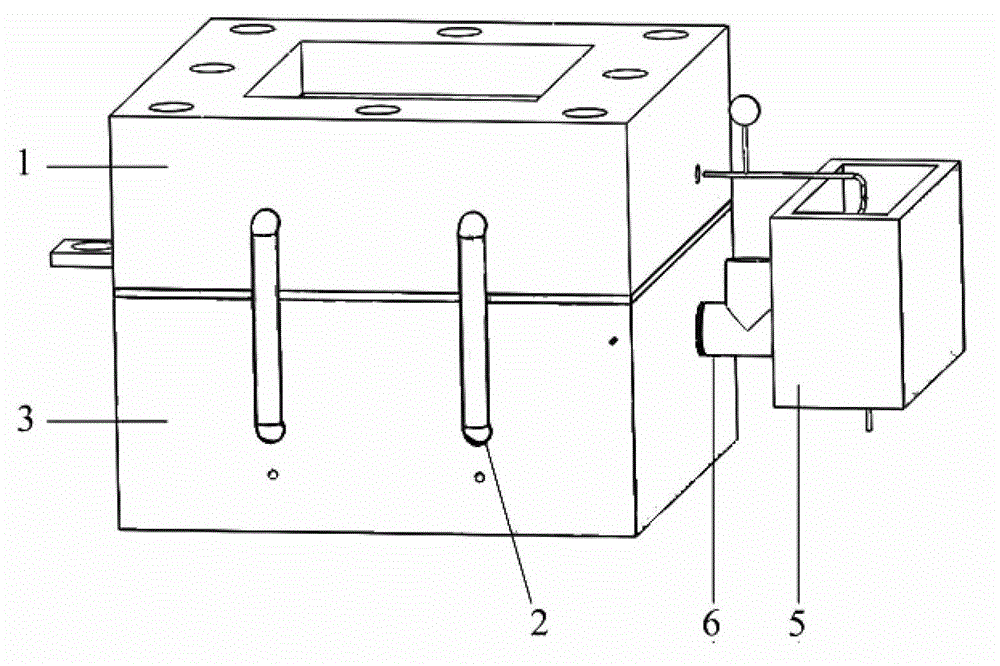

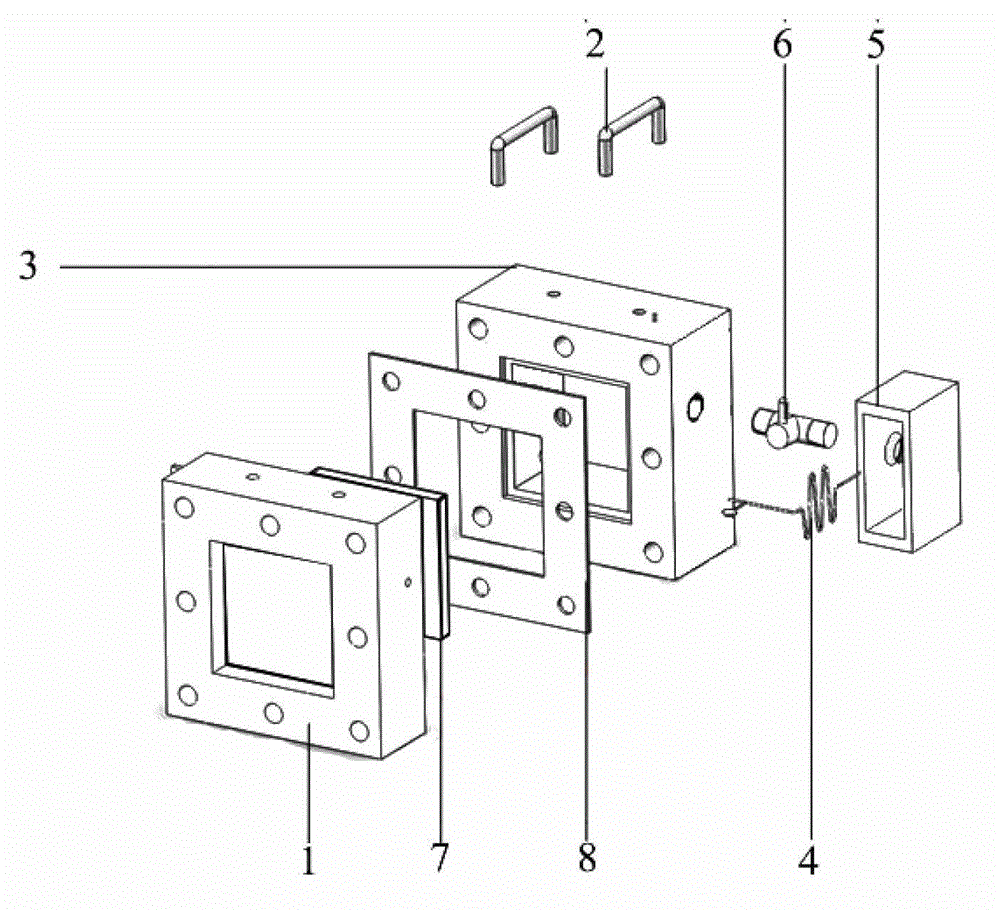

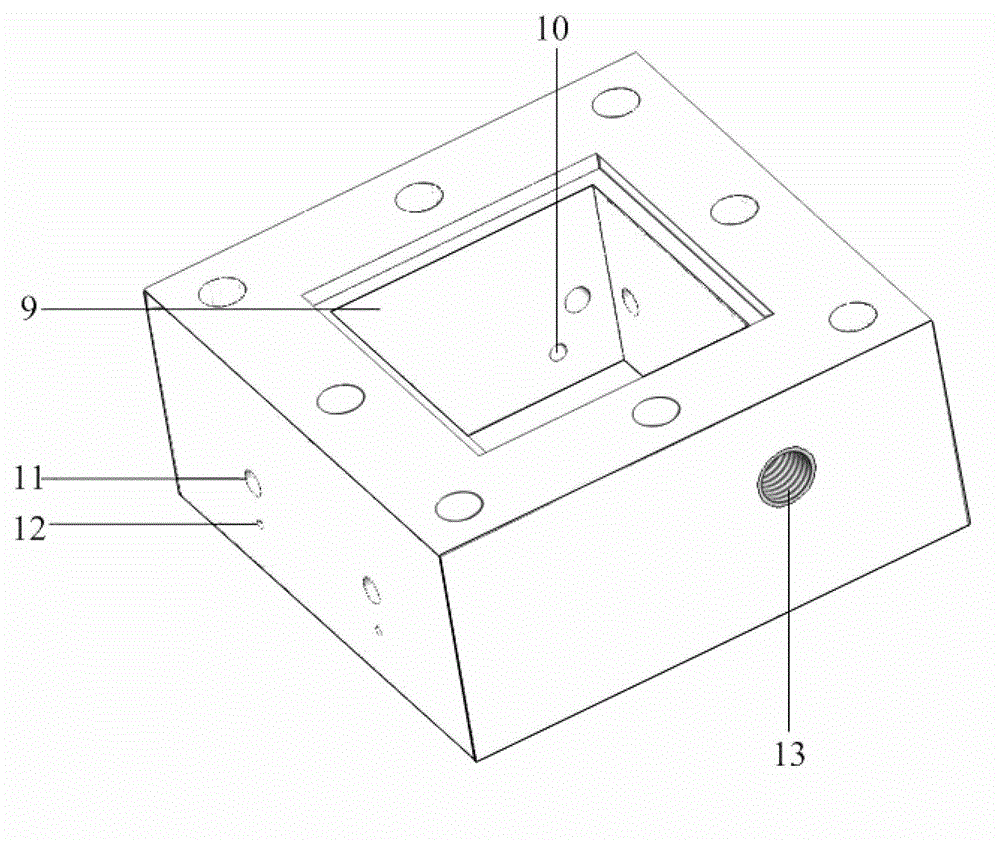

[0042] Heat / flow management system for passive direct methanol fuel cells, including evaporator 3, temperature control system, reactant recovery device, heat balance device, insulation layer; reactant recovery device includes serpentine pipeline 4 and methanol cooling box 5 One end of the serpentine pipeline 4 is connected to the reactant outlet of the battery reactant 1, and the other end passes through the through hole 20 at the bottom of the methanol cooling box 5, and the middle part is placed in the methanol chamber 21 of the methanol cooling box 5; the methanol cooling box 5 Placed in a room temperature environment, liquid methanol is stored inside, and the lower part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com