Carbohydrate compositions

A carbohydrate and composition technology, applied in the fields of food science, food preparation, application, etc., can solve the problem of not being able to give collinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

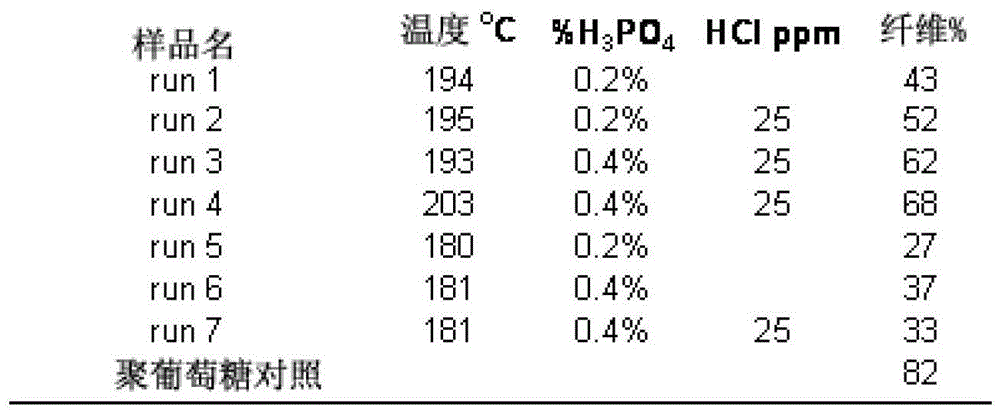

[0095] This example demonstrates preparations of carbohydrate compositions of the present invention that contain moderately high levels of dietary fiber.

[0096] by making Corn syrup (81% dry solids) was passed through a hot oil jacketed paddle mixer at a rate of 77 kg / h to evaporate it to less than 6% moisture. The rotor speed of the paddle mixer is usually set at 300-600rpm, and the oil jacket temperature varies from 150°C-205°C. In some tests, phosphoric acid was added at a rate that produced 0.1%-0.4% phosphoric acid solids on corn syrup solids. In some tests, hydrochloric acid was added at 25 ppm instead of or in addition to phosphoric acid.

[0097] The amount of fiber in the carbohydrate composition thus obtained was measured using the following method. A 25 mg sample of the carbohydrate composition was dissolved in 4 mL of pH 4.0 buffer and incubated with 100 microliters of a 10 mg / mL amyloglucosidase (Amyloglucoxidase Sigma Catalog #A-7255) solution for 2 hours a...

Embodiment 2

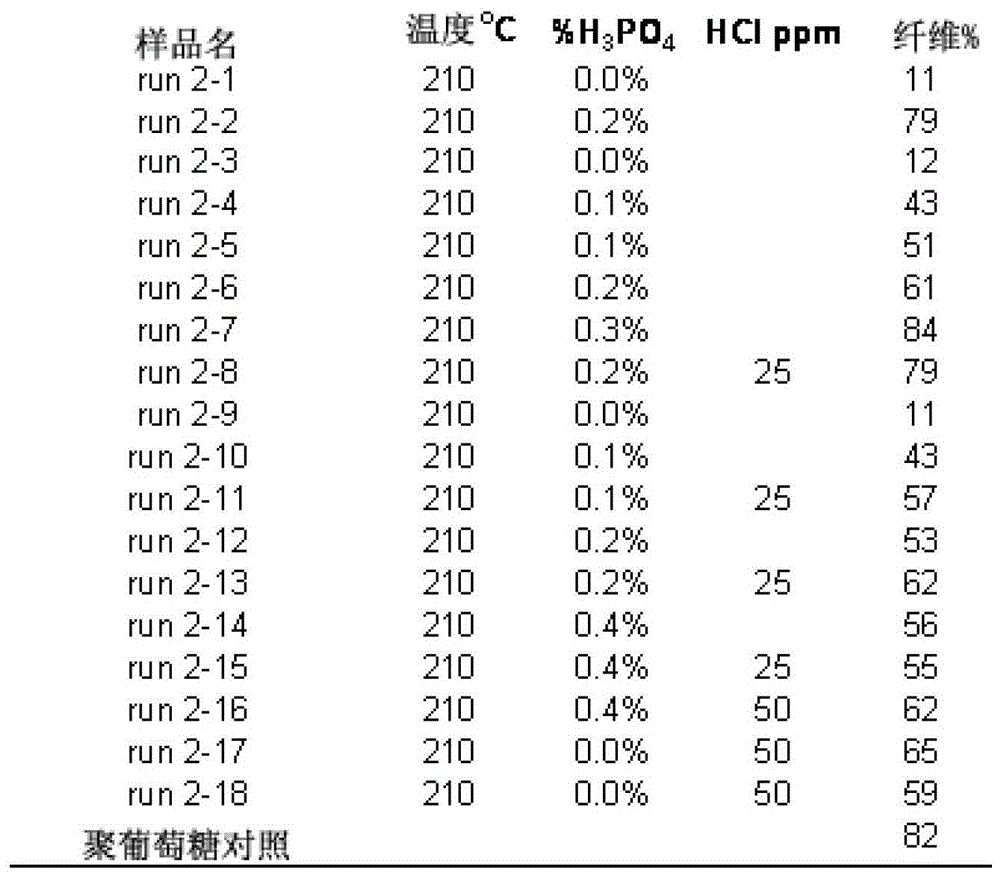

[0102] This example further demonstrates preparations of carbohydrate compositions of the present invention that contain moderately high levels of dietary fiber.

[0103] by making 4300 corn syrup (81%ds) was evaporated to less than 3% water content by passing through a hot oil jacket paddle mixer at a rate of 77kg / h. The rotor speed of the paddle mixer is typically set at 800 rpm and the oil jacket temperature is set at 210°C. In some tests, phosphoric acid was added at a rate that produced 0.1%-0.4% phosphoric acid solids on corn syrup solids. In some tests, hydrochloric acid was added at 25 or 50 ppm instead of or in addition to phosphoric acid.

[0104] The amount of fiber in the carbohydrate composition thus obtained was measured using the following method. A 25 mg sample of the carbohydrate composition was dissolved in 4 mL of pH 4.0 buffer and incubated with 100 microliters of a 10 mg / mL amyloglucosidase (Amyloglucoxidase Sigma Catalog #A-7255) solution for 2 hours ...

Embodiment 3

[0109] This example demonstrates preparations of carbohydrate compositions of the present invention having a relatively low sugar content and a relatively high fiber content.

[0110] A 50% ds w / w solution was prepared by adding water to the starting syrup (Table 3), which was prepared generally as described in Examples 1 and 2.

[0111] Table 3. Composition of starting syrup

[0112] DP1

DP2

DP3

DP4+

other sugar

TDF%

5.7

8.7

8.5

73.1

4.0

76.7

[0113] Sequential simulated moving bed (SSMB) chromatography was used to reduce the sugar content and increase the fiber content of the starting syrup. Transfer part of the starting syrup to the SSMB stock tank. The SSMB chromatography system was loaded with the potassium form of Dow 99-320 cation resin. The diluted feed was provided to the SSMB chromatograph at an average flow rate of 90 ml / min at 60–70°C. Desorption water (RO water) was added at a water / feed ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com