Grain oriented electrical steel sheet

A kind of electromagnetic steel plate, directional technology, applied in the direction of inorganic material magnetism, furnace, heat treatment equipment, etc., can solve the problem of limit, achieve the effect of noise suppression and excellent noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Manufactured by continuous casting, the component composition contains C: 0.060%, Si: 3.35%, Mn: 0.07%, Se: 0.016%, S: 0.002%, sol.Al: 0.025%, and N: 0.0090% by mass %, and The steel slab whose balance is Fe and unavoidable impurities is heated to 1400°C, hot-rolled into a hot-rolled sheet with a thickness of 2.2 mm, and then annealed at 1,000°C. Next, cold rolling was performed to have an intermediate plate thickness of 1.0 mm, and intermediate annealing was performed at 1000°C. Then, cold rolling was performed to obtain a cold-rolled sheet having a thickness of 0.23 mm.

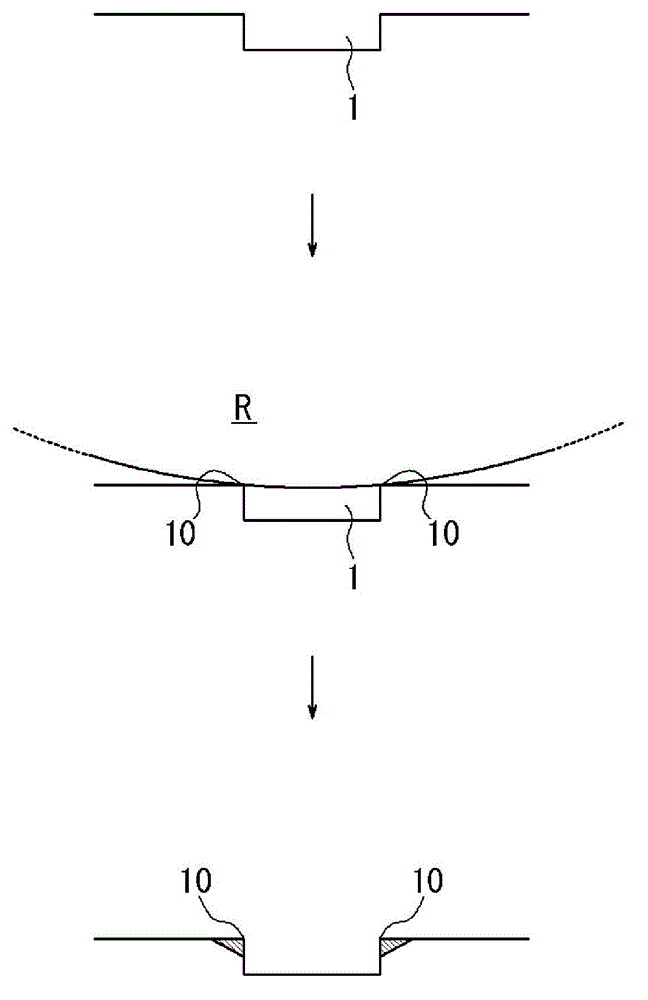

[0077] Then, a resist was applied by gravure offset printing, followed by electrolytic etching and resist stripping in alkaline solution, at intervals of 3 mm along the rolling direction at an inclination angle of 10° relative to the direction perpendicular to the rolling direction. Linear grooves with a width of 150 μm and a depth of 20 μm were formed.

[0078] Next, decarburization annealing was ...

Embodiment 2

[0086] Manufactured by continuous casting, the component composition contains C: 0.060%, Si: 3.35%, Mn: 0.07%, Se: 0.016%, S: 0.002%, sol.Al: 0.025%, and N: 0.0090% by mass %, and The steel slab whose balance is Fe and unavoidable impurities is heated to 1400°C, hot-rolled into a hot-rolled sheet with a thickness of 2.2 mm, and then annealed at 1,000°C. Next, cold rolling was performed to have an intermediate plate thickness of 1.0 mm, and intermediate annealing was performed at 1000°C. Then, cold rolling was performed to obtain a cold-rolled sheet having a thickness of 0.23 mm.

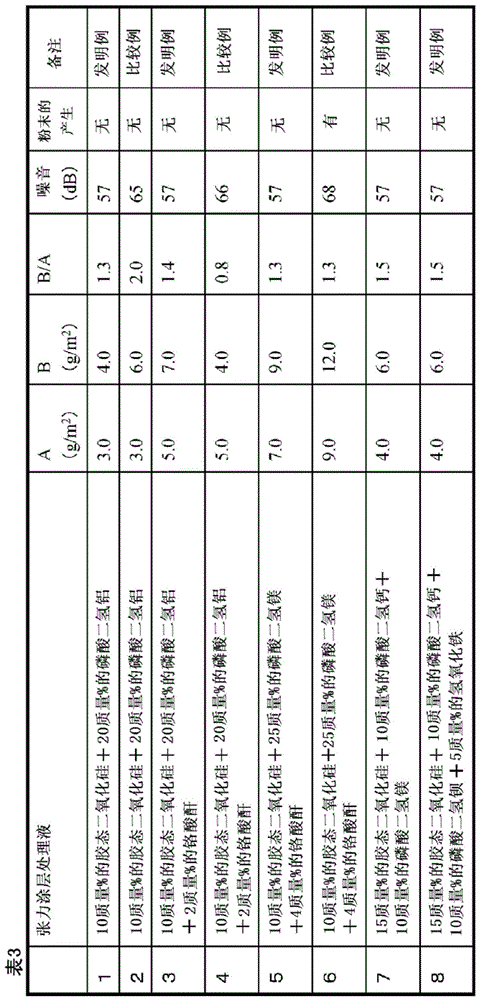

[0087] Next, decarburization annealing was carried out at 825°C, and then an annealing separator mainly composed of MgO was applied, and final annealing for the purpose of secondary recrystallization and purification was carried out at 1200°C for 10 hours. Then, a tension coating treatment liquid containing 5% by mass of colloidal silica and 25% by mass of magnesium dihydrogen phosphate was applied,...

Embodiment 3

[0095] Manufactured by continuous casting, the composition consists of C: 0.070%, Si: 3.20%, Mn: 0.07%, S: 0.02%, sol.Al: 0.025%, and N: 0.0090% by mass%, and the balance is Fe and The steel slab with unavoidable impurities was heated to 1400°C, and then hot-rolled into a hot-rolled sheet with a thickness of 2.2mm, and then the hot-rolled sheet was annealed at 1,000°C. Next, cold rolling was performed to have an intermediate thickness of 2.0 mm, intermediate annealing was performed at 1000° C., and then cold rolling was performed to obtain a cold-rolled sheet having a thickness of 0.29 mm.

[0096] Then, a resist was applied by gravure offset printing, followed by electrolytic etching and resist stripping in alkaline solution, at intervals of 3 mm along the rolling direction at an inclination angle of 10° relative to the direction perpendicular to the rolling direction. Linear grooves with a width of 150 μm and a depth of 20 μm were formed.

[0097] Next, decarburization anne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com