Method for producing paper

A manufacturing method and technology of a control agent, which are applied in the directions of paper, papermaking, textiles and papermaking, etc., can solve the problems of increasing the drainage load, difficult to remove, and increase the manufacturing cost, and achieve the effect of reducing the drainage load and suppressing the reduction of paper quality.

Active Publication Date: 2013-04-24

KURITA WATER INDUSTRIES LTD

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In addition, glucose and organic acids have low molecular weight, so they are difficult to remove, which causes increased drainage load

In addition, as starch added to improve paper strength, printability, etc., since the action of amylase disappears from the pulp, starch needs to be added, sprayed or coated again, which will also lead to an increase in manufacturing costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

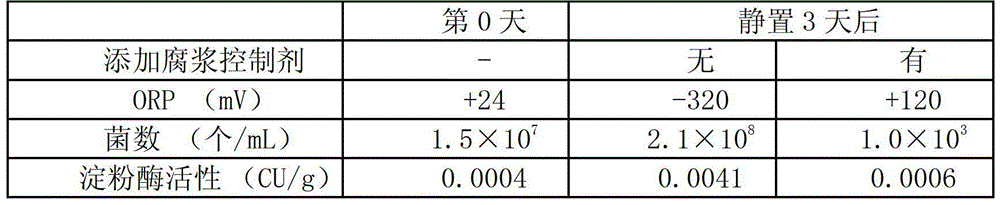

[0060] The effects of the present invention will be specifically described below with reference to Examples and Comparative Examples of the present invention. In this example, the environmental load reduction effect and the performance of the produced paper when the present invention was applied were evaluated by the method described below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

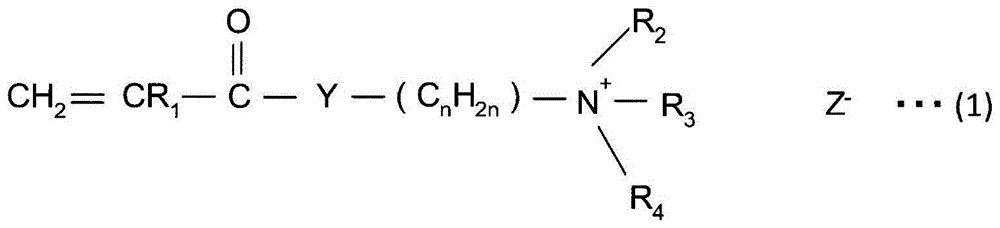

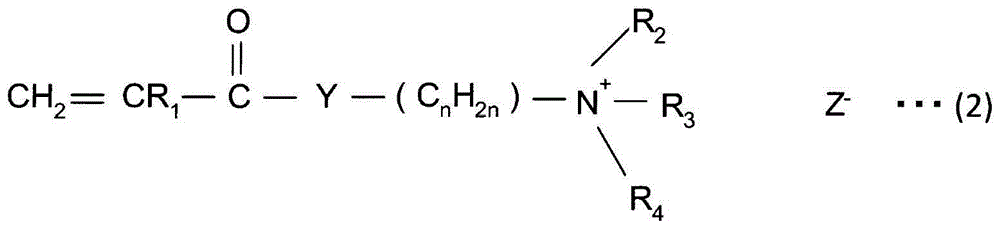

A method for producing paper that reduces the load on drainage and that obtains cardboard and paper having a fixed quality is provided. A slime control agent and a polymer having a cationic functional group are added to papermaking-step water containing starch. At that time, as the polymer containing a cationic functional group, a compound is used that is a polymer of solely a monomer represented by chemical formula (A) or a copolymer of said monomer and acrylamide or styrene, contains 20-100 mol% of a monomer unit derived from the monomer represented by chemical formula (A), is at least one of a diallyl dimethyl ammonium halide polymer, a polyethylenimine, or an epichlorohydrin polymer, and has an intrinsic viscosity (?) at 25 DEG C in a 1 N sodium chloride solution of 0.05-5 dl / g. (In the formula: R1 represents a hydrogen atom or a methyl group; R2 and R3 each represent a C1-4 alkyl group; R4 represents a hydrogen atom, a C1-4 alkyl group, or a benzyl group; Y represents O or NH; n represents 2-5; and Z- represents a halogen ion, a sulfate ion, a phosphate ion, a borate ion or an organic acid anion.).

Description

technical field [0001] The present invention relates to a method for producing paper and board. In more detail, it relates to the technique for improving the water quality of the water discharged|emitted from the manufacturing process of the paper which uses starch. Background technique [0002] In the paper manufacturing process, starch is used as a paper strength enhancer, a surface strength enhancer, or an interlayer binder for maintaining the strength and printability of paper. In addition, in recent years, the utilization rate of waste paper in paper production has been increasing, but for example, the covering layer of waste paper, the glue of cardboard waste paper, etc., the waste paper used often contains starch. [0003] For this reason, a large amount of starch is contained in the water used in the papermaking process. If these starches are used as a nutrient source, bacteria and other microorganisms will form a sludge called "sludge" on the pipes, tank walls, fil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H21/02D21H17/44

CPCD21H17/45D21H21/02D21H17/375D21H17/35

Inventor 大草优子田口千草

Owner KURITA WATER INDUSTRIES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com