Magnetoresistive element and magnetic random-access memory

A technology of random access memory and magnetoresistive effect element, applied in static memory, digital memory information, magnetic field controlled resistor, etc., can solve the problem of difficult to control the pulse width of the element with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

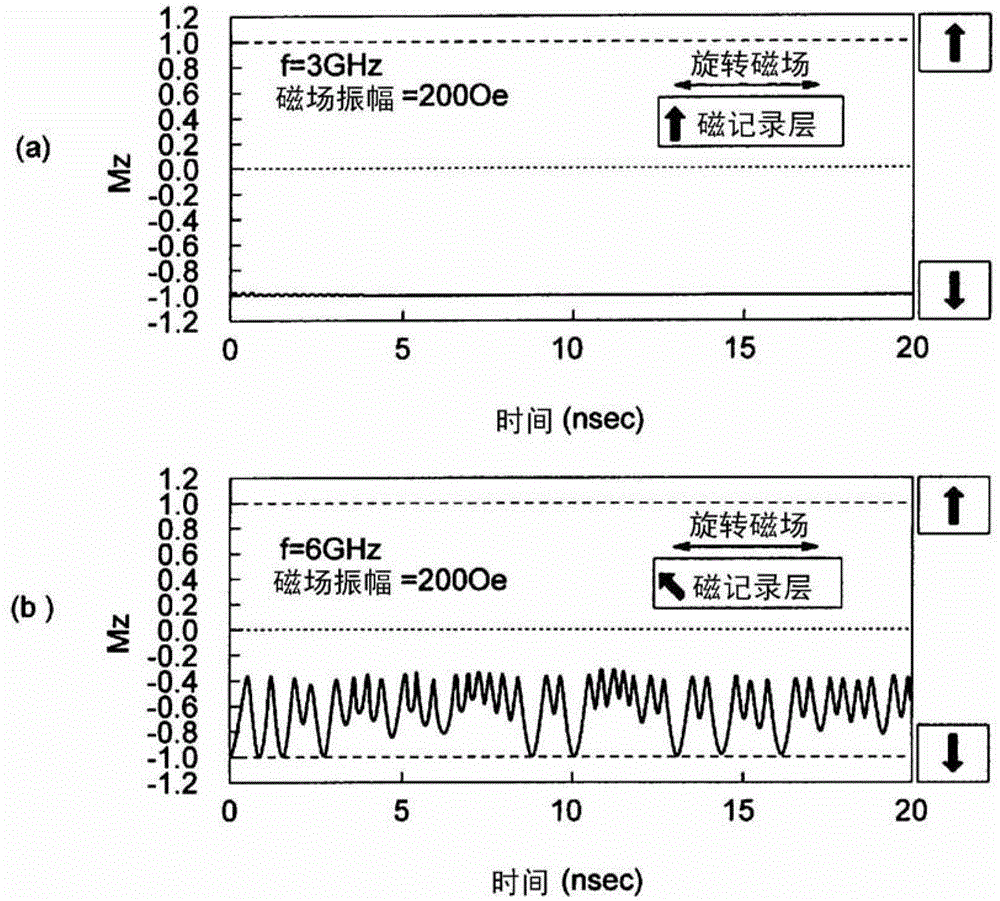

[0048] Figure 5 The magnetoresistance effect element of the first embodiment is shown in . The magnetoresistance effect element 1 of this embodiment has a laminated structure consisting of a magnetic recording layer 12 whose magnetization direction can be changed, a tunnel barrier layer 14, a magnetic reference layer 16 whose magnetization direction is substantially fixed, an isolation layer 18, and a magnetic rotation layer 12. Layers 20 are stacked in this order or in the reverse order.

[0049] The magnetic recording layer 12 has a ferromagnetic layer capable of changing the direction of magnetization before and after energization when the direction of magnetization is substantially perpendicular to the film surface and current is passed to the magnetoresistive element 1 . The magnetic reference layer 16 has a ferromagnetic layer. Even if the magnetization direction of the ferromagnetic layer is substantially perpendicular to the film surface and a current is passed throu...

no. 2 Embodiment approach )

[0080] Generally, in a magnetoresistive element using a magnetic film having perpendicular magnetization (perpendicular magnetization film), the leakage field from the magnetic reference layer acts on the magnetic recording layer, and the stability of information "0" and "1" is unstable. symmetry. Therefore, in order to reduce the influence of the leakage field from the magnetic reference layer, the magnetoresistance effect element of the second embodiment is configured to include a magnetic field adjustment layer having magnetization in the opposite direction to the magnetization of the magnetic reference layer. Figure 12 The magnetoresistance effect element of this second embodiment is shown in . exist Figure 5 In the magnetoresistance effect element of the first embodiment shown, the magnetoresistance effect element 1 of the second embodiment is configured such that a non-magnetic metal layer 11 is interposed on the side of the magnetic recording layer 12 opposite to the...

no. 3 Embodiment approach )

[0084] Figure 14 A magnetoresistance effect element of a third embodiment is shown in . The magnetoresistance effect element 1 of the third embodiment is configured by Figure 5 In the magnetoresistance effect element of the first embodiment shown, an antiferromagnetic coupling film 20A is used as the magnetic rotation layer 20 . This antiferromagnetic coupling film 20A has a laminated structure in which a ferromagnetic layer 20a, a nonmagnetic layer 20b, and a ferromagnetic layer 20c are sequentially laminated on the isolation layer 18, and the ferromagnetic layer 20a and the ferromagnetic layer 20c are reversed via the nonmagnetic layer 20b. ferromagnetic coupling.

[0085] In the magnetoresistive effect elements of the first to second embodiments, a magnetic film having in-plane magnetization (in-plane magnetization film) is used as the magnetic rotation layer 20, so there is a complex magnetic domain structure such as an eddy current magnetic domain structure Case. If...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com