Lactobacillus paracasei fermented feed and preparation method thereof, fermenting equipment and application of lactobacillus paracasei fermented feed

A technology of fermented feed and fermentation equipment, which is applied in the field of Lactobacillus paracasei fermented feed and its preparation, can solve the problems of low nutritional value of Lactobacillus paracasei fermented feed, micro-ecological imbalance, increased antibiotic consumption, etc., and achieve improved feed Effects of conversion utilization efficiency, reduction of incidence, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of Lactobacillus paracasei fermented feed of the present invention comprises the following steps:

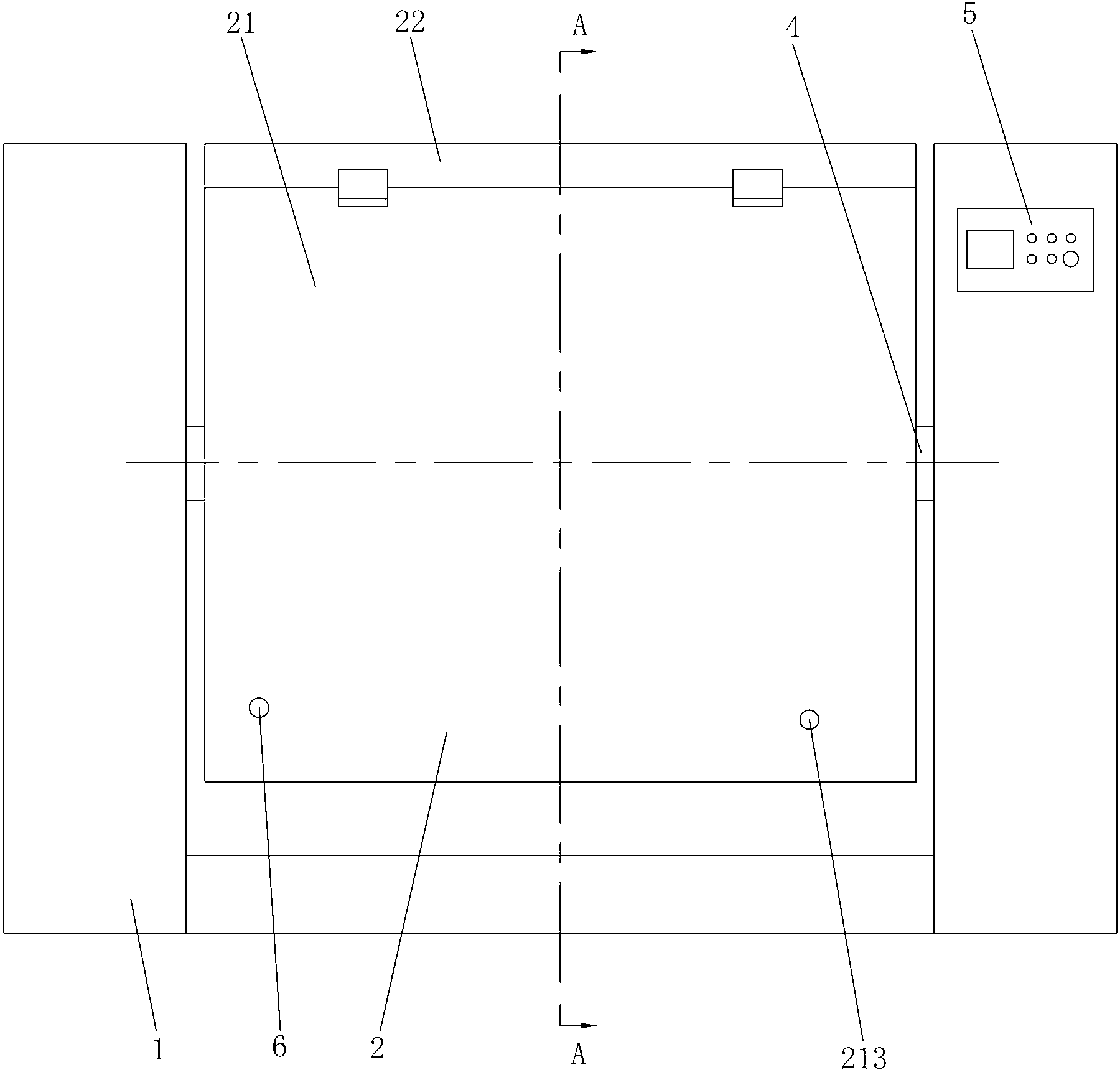

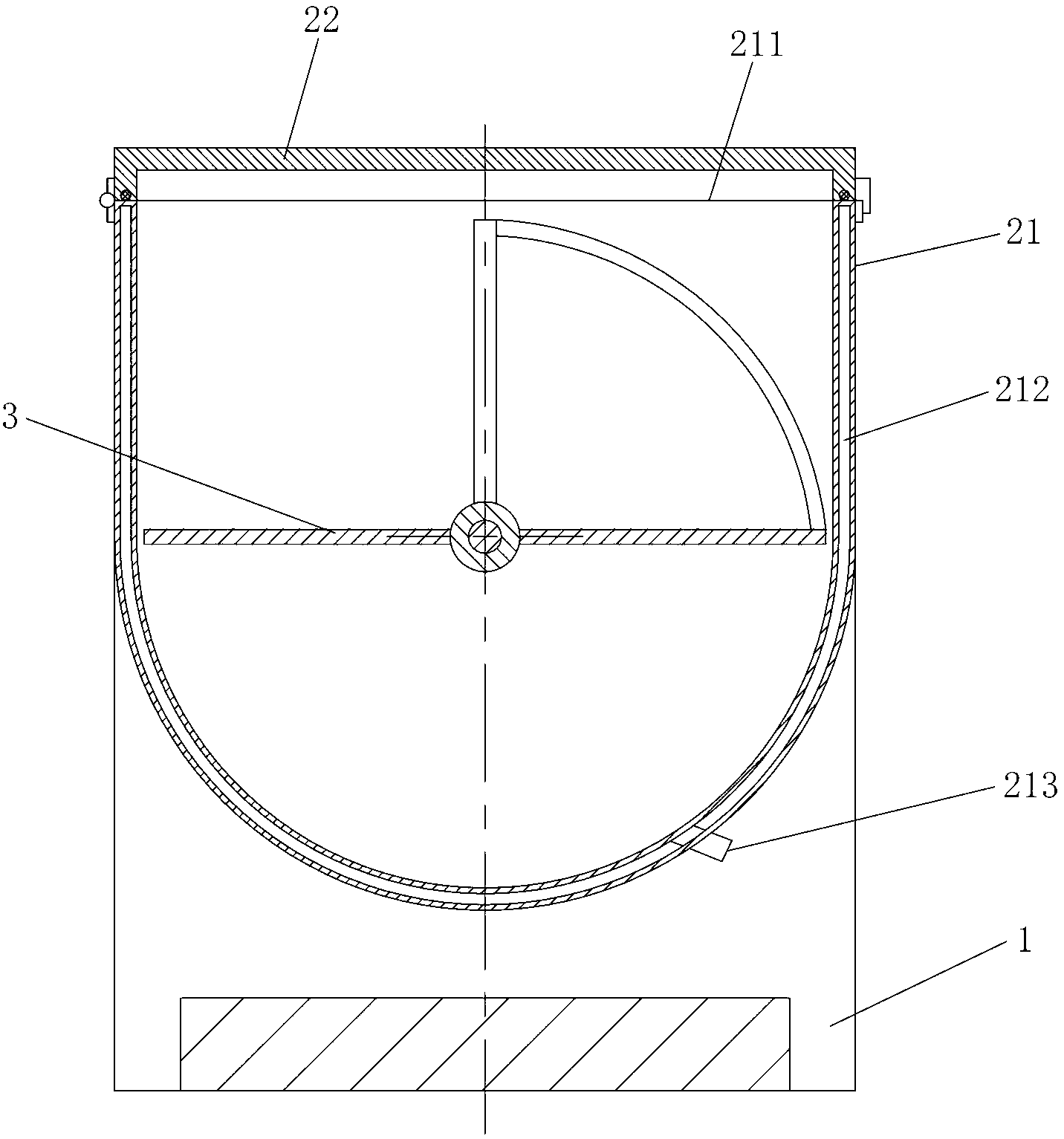

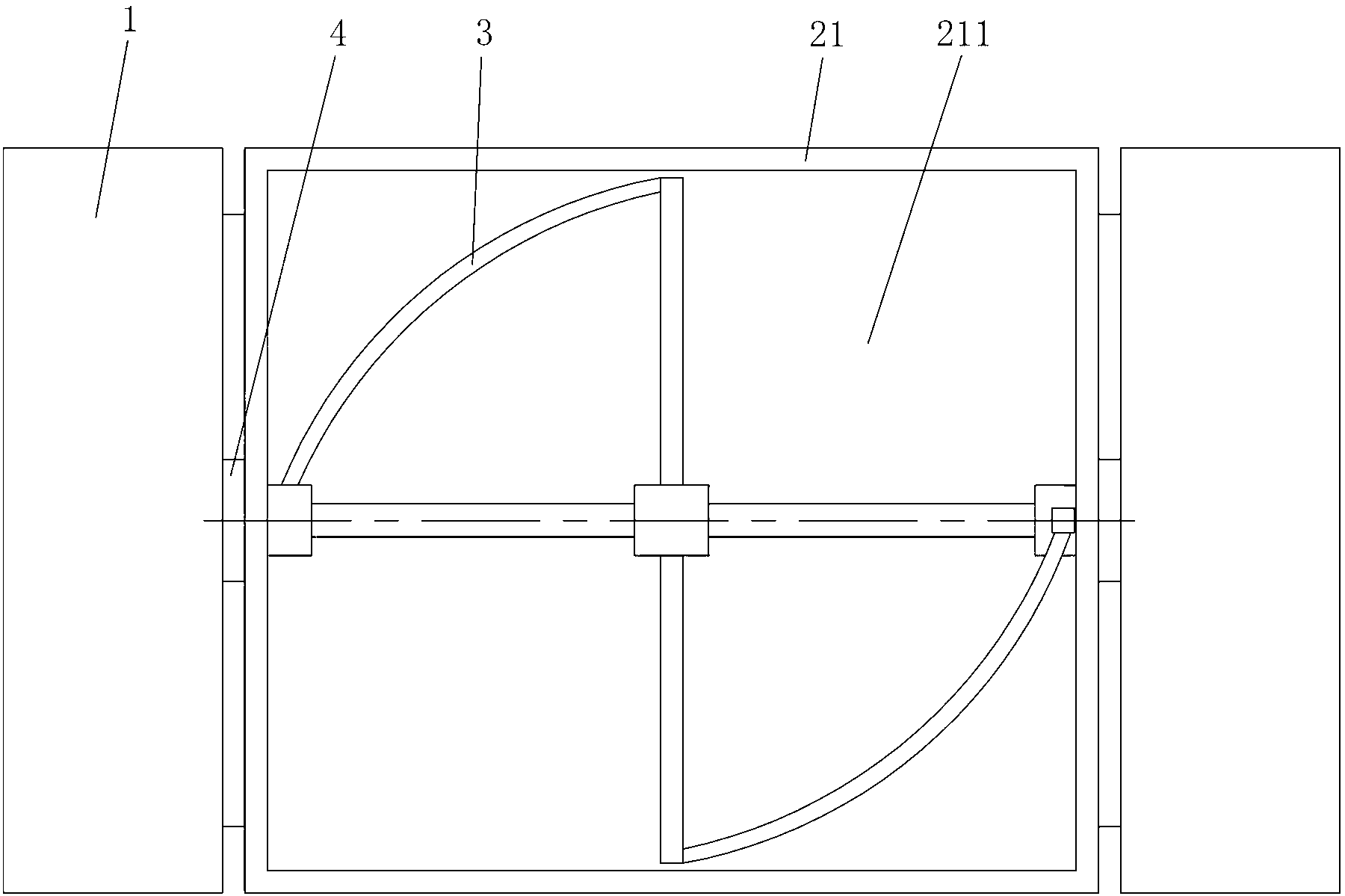

[0029] (1) Liquid fermentation of Lactobacillus paracasei: put the MRS liquid medium into the chamber of the fermentation equipment (the fermentation equipment can be a fermentation tank, a fermentation tank or a plastic container, and the fermentation equipment in Example 4 is selected in this embodiment) In the process, the liquid volume of the MRS liquid medium accounts for 20% of the volume of the cavity, and 115°C high-temperature steam is passed into the container for 20 minutes to complete the sterilization of the MRS liquid medium. After the sterilization is completed, cool down and sterilize the MRS The liquid medium is inoculated with Lactobacillus paracasei (strain preservation number: CICC 20296), the inoculum amount is 3%, the container is sealed after inoculation, and the paracasei milk is obtained after static culture at a temperature of...

Embodiment 2

[0038] A preparation method of Lactobacillus paracasei fermented feed of the present invention comprises the following steps:

[0039] (1) Liquid fermentation of Lactobacillus paracasei: put the MRS liquid medium into the chamber of a fermentation equipment (the fermentation equipment in Example 4 was selected in this embodiment), the liquid volume of the MRS liquid medium accounts for 25% of the volume of the cavity, inject high-temperature steam at 115°C into the container for 20 minutes to complete the sterilization of the MRS liquid medium, cool down after the sterilization is completed, and carry out Lactobacillus paracasei (strain preservation) on the MRS liquid medium No.: CICC 20296), the inoculum amount is 6%, the container is sealed after inoculation, and the liquid of Lactobacillus paracasei is obtained after static cultivation at a temperature of 37°C for 48 hours, and the fermentation liquid of Lactobacillus paracasei is obtained. The number of bacteria contained ...

Embodiment 3

[0042] A preparation method of Lactobacillus paracasei fermented feed of the present invention comprises the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com