Peach juice and preparation method thereof

A technology for peach juice and peach pieces, applied in the field of peach juice and its preparation, can solve the problems of inability to guarantee flavor and sensory quality, difficult to see pure peach juice products, perishability, etc., to simplify the packaging process and prevent endogenous enzymes. Browning-promoting, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

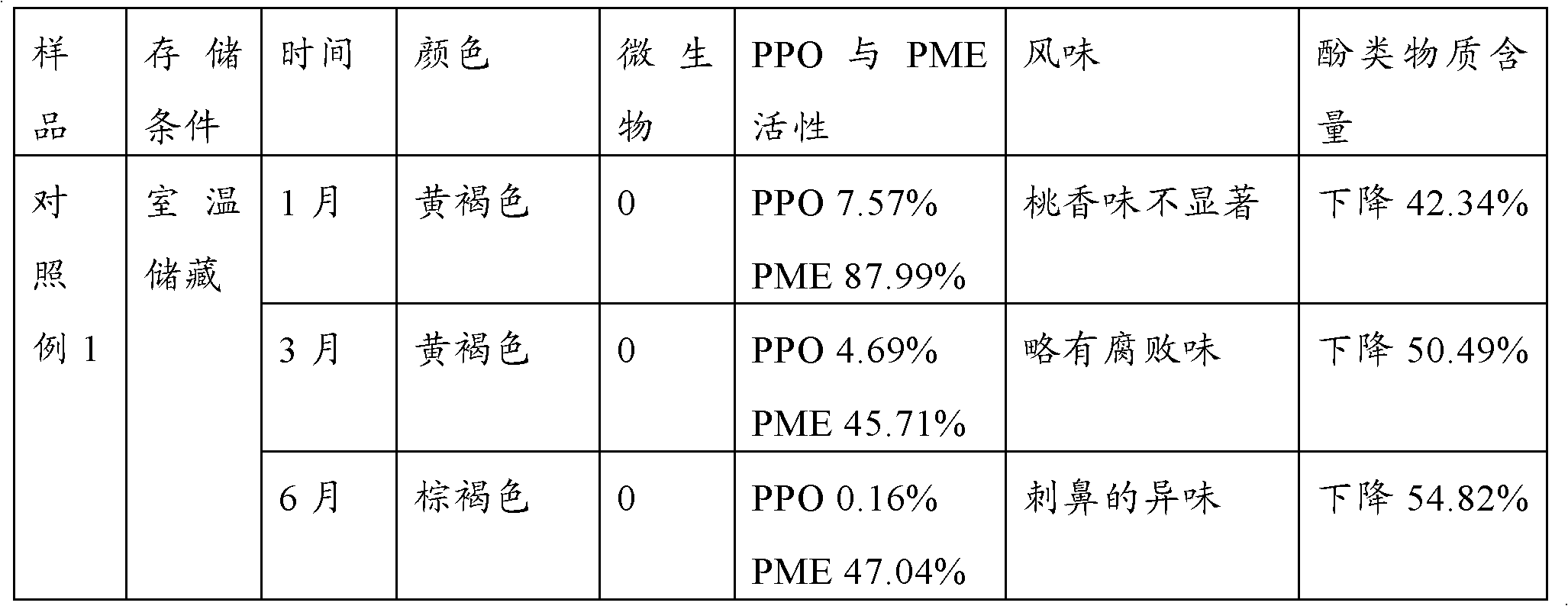

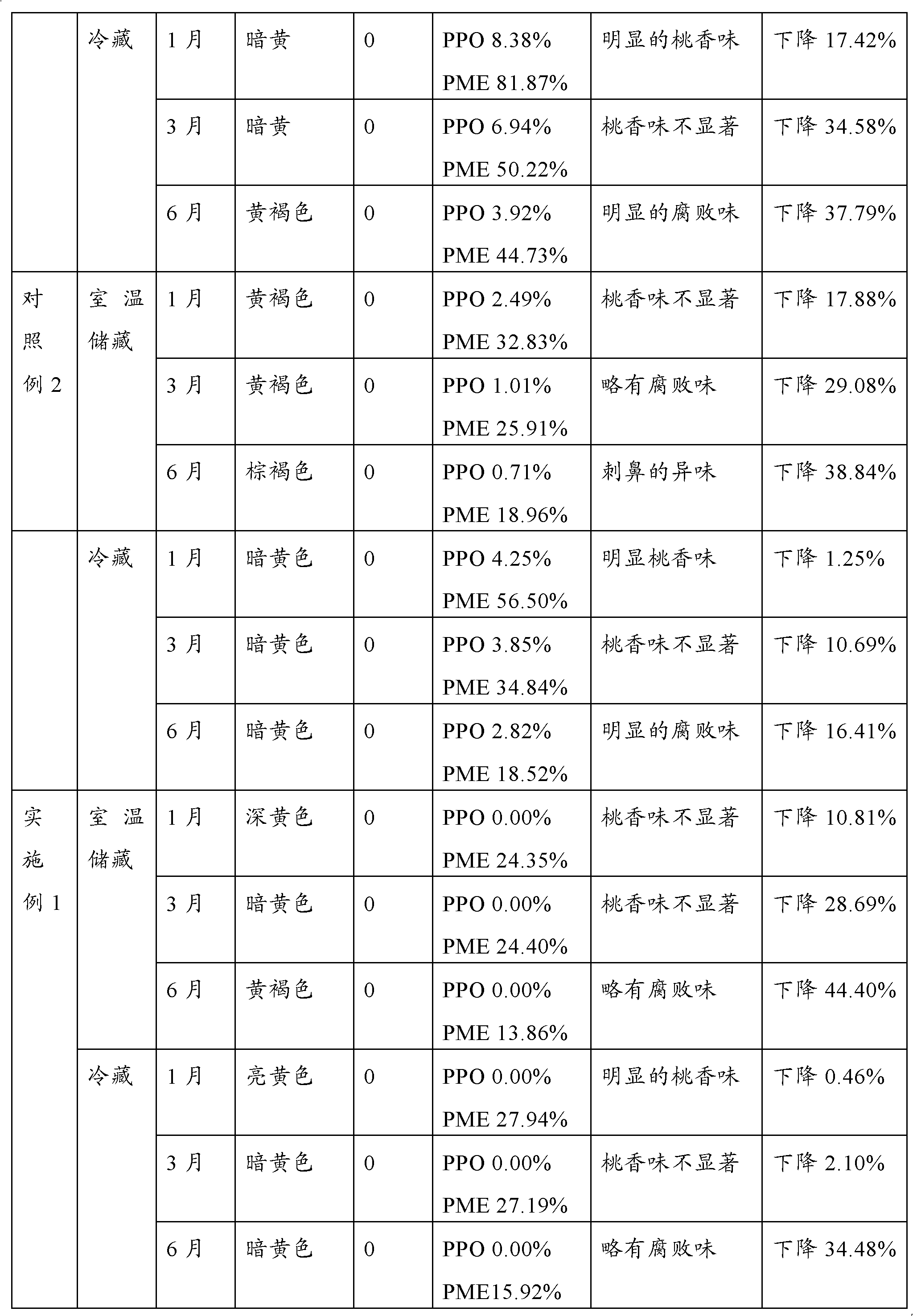

Embodiment 1

[0035] The preparation method of peach juice is to wash the picked fresh peaches, cut them into 6-8 small pieces, and then process them according to the following steps:

[0036] (1), blanching: put the cut peach pieces in boiling water for 2 minutes.

[0037] (2) Juicing: squeeze the blanched peach pieces to obtain the primary product of peach juice. Using a screw juicer (the juice squeezed out by the screw juicer can be directly homogenized, and the pomace is collected through another outlet) to repeatedly squeeze twice, that is, after the first squeeze, the filtered pulp and peel Squeeze twice, collect the peach juice that squeezes out; Add 0.1% sodium erythorbate (in the form of a 1% solution) of the total weight of peach pieces when squeezing the juice to avoid browning of the peach juice during the squeezing process.

[0038] (3), homogenization: control the pressure of the homogenizer to 20-30MPa, and homogenize twice.

[0039] (4), adjust pH value: adopt citric acid ...

Embodiment 2

[0056] Raw materials—cleaning—cutting into pieces (each peach is cut into 6-8 small pieces)—blanching (boiling water, 3min) juicing (adding D-sodium erythorbate with a mass concentration of 1%, D- The quality of sodium erythorbate is 0.1% of the peach block weight)—homogeneous (20-30MPa, twice)—allocation (using citric acid to adjust the pH to about 3.7)—bag vacuum sealing—high static Pressure treatment (650MPa, 15min) - finished product.

[0057] The results show that after the above treatment, the microorganisms in the peach juice can be completely reduced by more than 7 logarithms, and the polyphenol oxidase (PPO) and lipoxygenase (LOX) in the peach juice can be completely inactivated, and the pectin methyl ester can be inactivated. The activity of the enzyme (PME) is about 60.4%. And the peach juice can be stored for more than 3 months under cold storage and room temperature conditions, and maintain good peach flavor under cold storage conditions.

Embodiment 3

[0059] Raw materials—cleaning—cutting into pieces (each peach is cut into 6-8 small pieces)—blanching (boiling water, 1.5min) juicing (adding a mass concentration of 1% D-sodium erythorbate solution at the same time, D - the quality of sodium erythorbate is 0.1% of the weight of the peach block) - homogeneous (20-30MPa, twice) - deployment (using sodium citrate to adjust the pH to about 3.7) - bagging and vacuum sealing - High static pressure treatment (550MPa, 20min) - finished product.

[0060] The results show that after the above treatment, the microorganisms in the peach juice can be completely reduced by more than 7 logarithms, and the polyphenol oxidase (PPO) and lipoxygenase (LOX) in the peach juice can be completely inactivated, and the pectin methyl ester can be inactivated. The activity of the enzyme (PME) is about 66.9%. And the peach juice can be stored for more than 3 months under cold storage and room temperature conditions, and maintain good peach flavor under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com