Method for preparing oriented silicon steel with asymmetrical rolling technique

A technology of asynchronous rolling and oriented silicon steel, applied in metal rolling, temperature control, tension/pressure control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

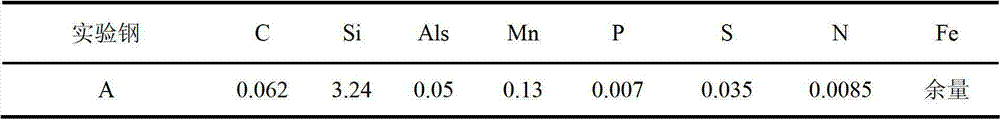

[0011] The experimental steel A is the Hi-B scheme, the chemical composition is shown in Table 1 (%), and the conventional hot-rolled strip steel production process (line) is adopted, and the characteristic is that the method for realizing asynchronous rolling is: for the roughing mill or the finishing mill, the work roll The rotating speed is the same, but the diameters of the upper and lower work rolls are different. The circumferential speed ratio of the upper and lower work rolls of the asynchronous rolling mill is 1:1.20. The billet heating temperature is 1360°C, and the rough rolling start temperature is 1350°C. It is divided into 5 hot rolling passes. The first two passes are asynchronous hot rolling. The rolling schedule is as follows: 240mm→144mm→100mm asynchronous hot rolling→72mm→54mm→ 40mm choose conventional or asynchronous hot rolling, the final rolling temperature is 1220°C; the finishing rolling stage is divided into 7 passes, the starting rolling temperature i...

Embodiment 2

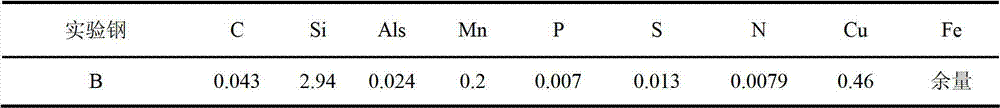

[0016] Experimental steel B is low-temperature heating GO steel, and its chemical composition is shown in Table 2 (%). It adopts a conventional hot-rolled strip production process (line), and is characterized in that the method for realizing asynchronous rolling is: for rough rolling mill or finishing mill, The diameter of the lower work roll is the same, but the rotation speed of the work roll is different. The circumferential speed ratio of the upper and lower work rolls of the asynchronous rolling mill is 1:1.15. The billet heating temperature is 1280°C, and the rough rolling start temperature is 1280°C. It is divided into 5 passes of hot rolling. The first two passes adopt asynchronous hot rolling. The rolling procedure is as follows: asynchronous hot rolling is used between 240mm→144mm→100mm Select conventional or asynchronous hot rolling at →72mm→54mm→40mm, the final rolling temperature is 1140°C; the finishing rolling stage is divided into 7 passes, and the starting rol...

Embodiment 3

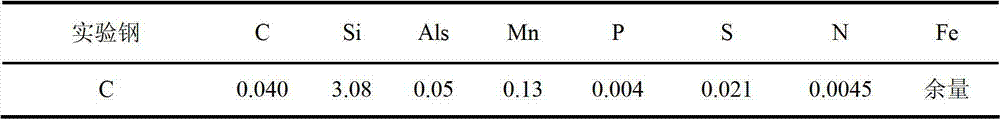

[0021] The chemical composition of the experimental steel C is GO steel is shown in Table 3 (%), using a conventional hot-rolled strip steel production process (line), which is characterized in that the method of realizing asynchronous rolling is: for the rough rolling mill or finishing mill, the upper and lower work The roll diameter is the same, and the friction coefficient between the upper and lower work roll surfaces and the rolled piece is changed. The circumferential speed ratio of the upper and lower work rolls of the asynchronous rolling mill is 1:1.10. The billet heating temperature is 1300°C, and the rough rolling start temperature is 1300°C. It is divided into 5 passes of hot rolling. The first two passes are asynchronous hot rolling. The rolling schedule is as follows: 240mm→144mm→100mm asynchronous hot rolling→72mm→54mm→ 40mm choose conventional or asynchronous hot rolling, the final rolling temperature is 1200 ℃; the finishing rolling stage is divided into 7 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com