Processing device before spraying

A treatment device and combined technology, applied in the direction of neutralization water/sewage treatment, metal material coating process, etc., can solve problems such as environmental pollution, affecting treatment effect, and high pool body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The specific features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

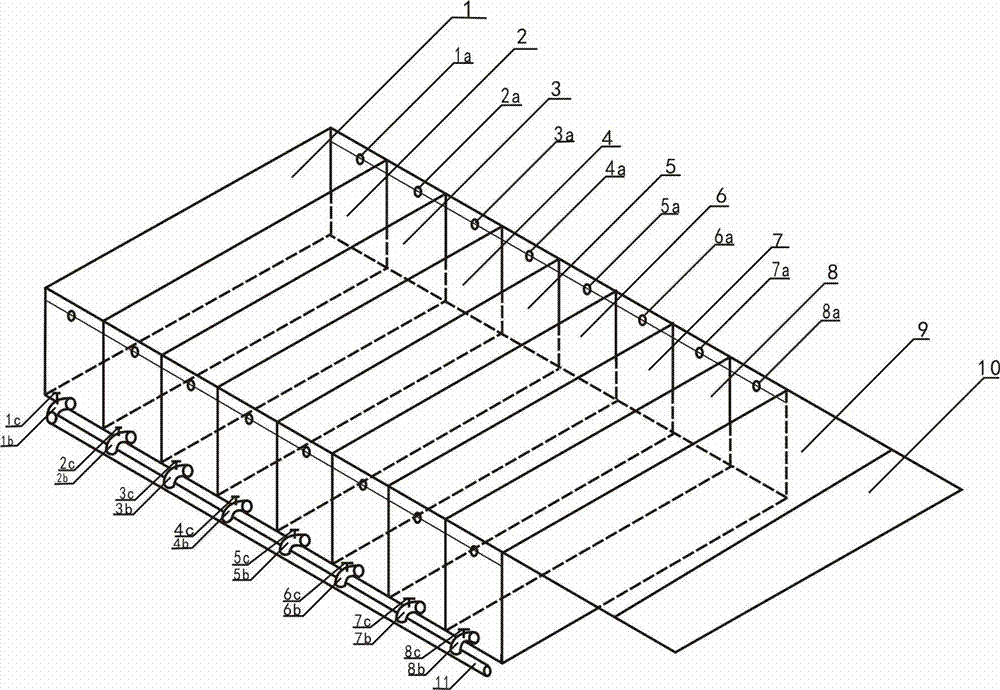

[0007] see figure 1 , including: alkali washing pool (1), water washing pool (2), pickling pool (3), two clear water pools A (4), clear water pool B (5), chromating pool (6), clear water pool C ( 7), clear water pool D (8), Lishui area (9), drying furnace (10), overflow holes (1a, 2a, 3a, 4a, 5a, 6a, 7a, 8a), sewage pipes (1b, 2b, 3b, 4b, 5b, 6b, 7b, 8b), drain valve (1c, 2c, 3c, 4c, 5c, 6c, 7c, 8c) and header (11); when in use, through the header ( 11) Inject clean water into each pool respectively, close the drain valve after reaching the predetermined water volume, and dispense acid and alkali doses according to the demand according to the water volume in each pool, and start the air pump to pneumatically stir the alkali washing pool (1) and the pickling pool (3) And the chromating pool (6), during the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com