Method for synthesizing hydrogenated butadiene-acrylonitrile rubber by nano-Pd/C catalyst

A technology for hydrogenating nitrile butadiene rubber and nitrile butadiene rubber, which is applied in the field of fine chemicals, can solve the problems of harsh reaction conditions, incomplete conversion, and high cost of synthesizing hydrogenated nitrile butadiene rubber, and achieves the effect of mild reaction conditions and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

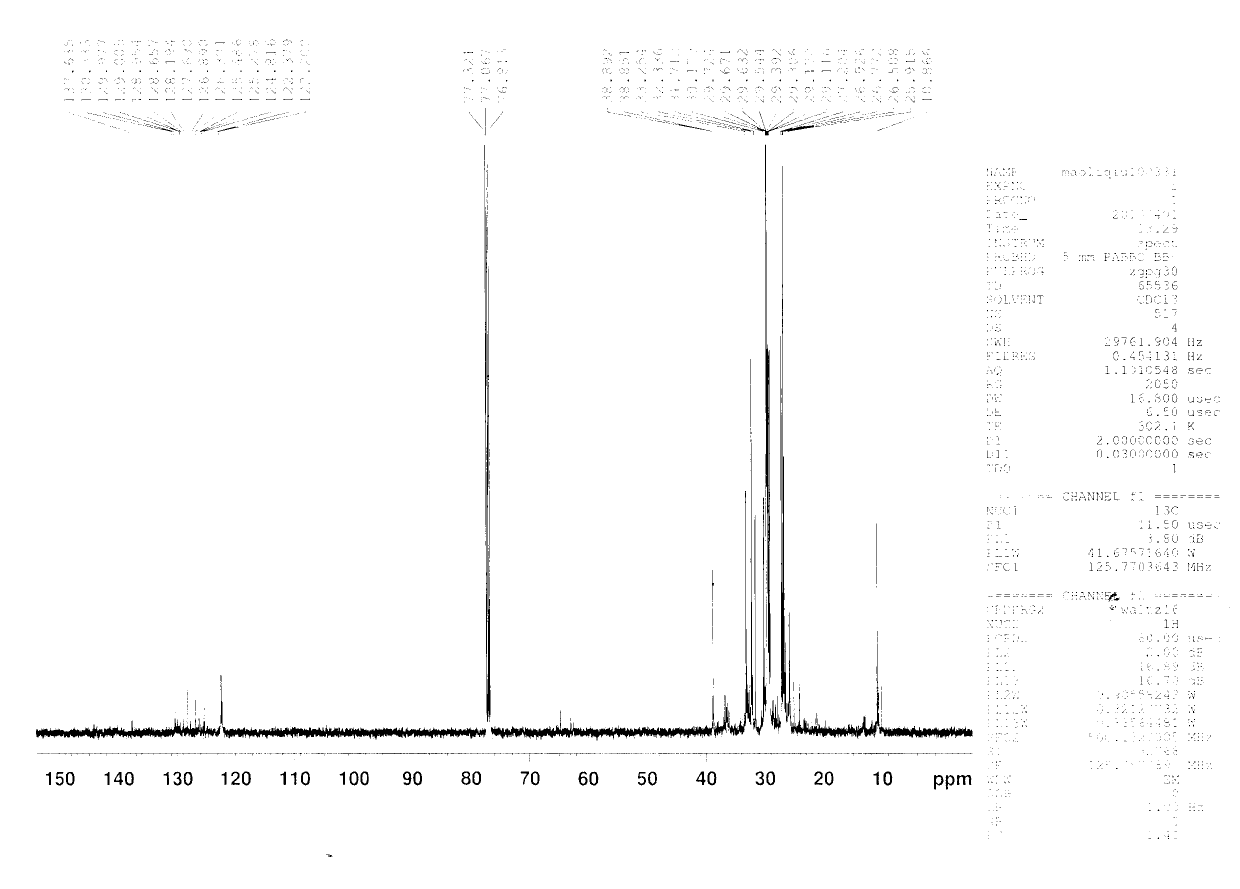

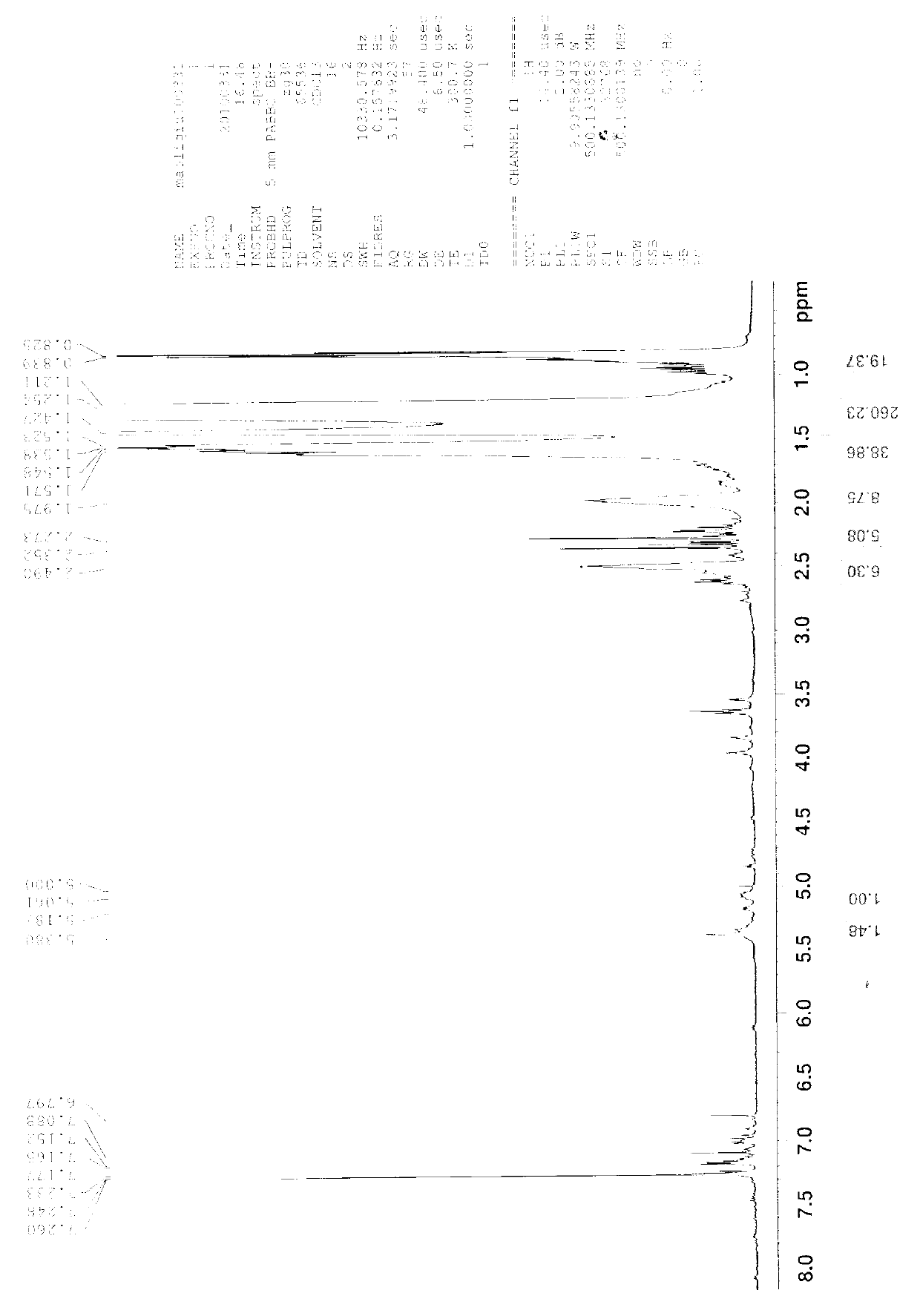

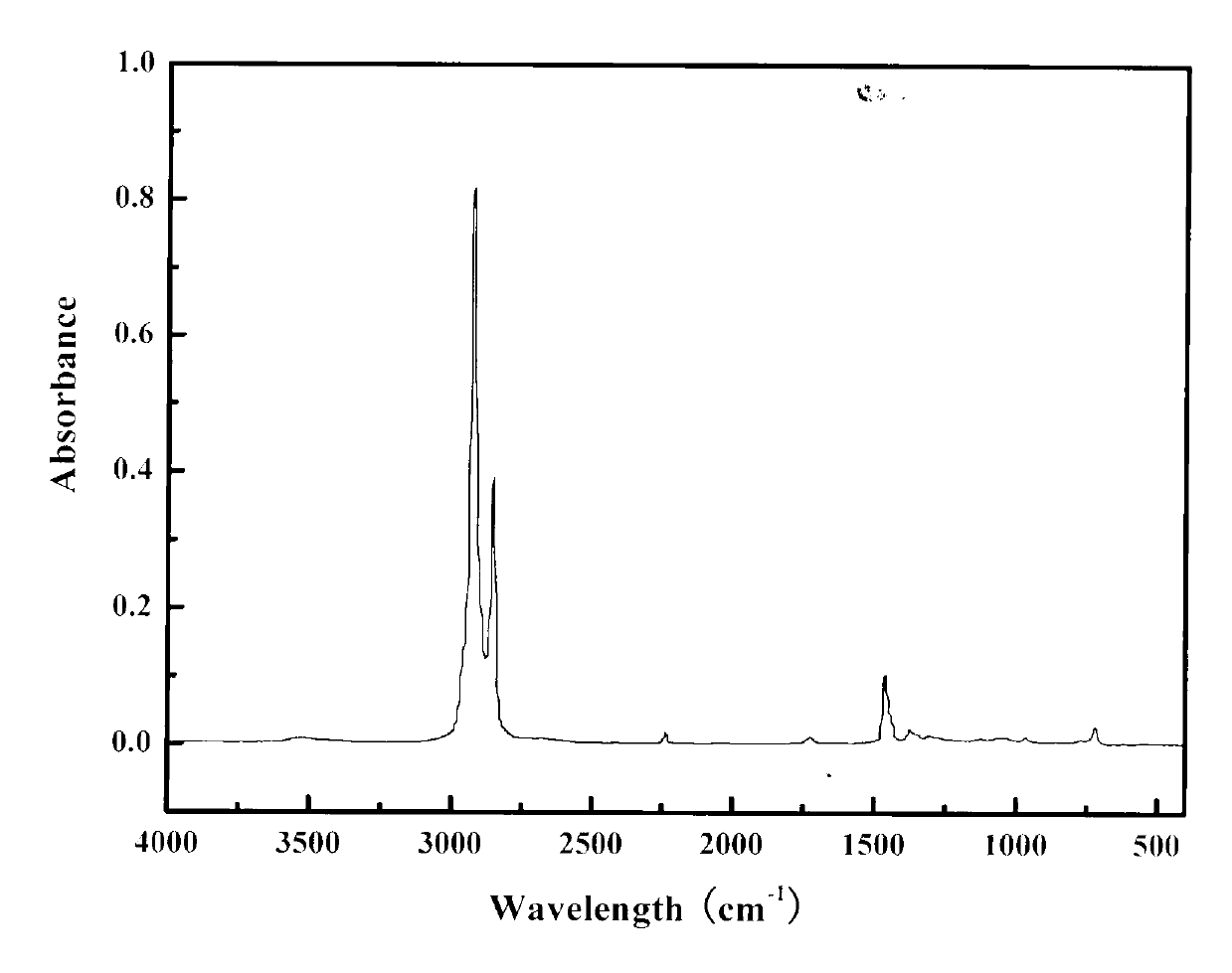

[0044] Accurately weigh 25 g NBR, 2.5 g 3wt% Pd / C catalyst prepared by CN 101966455 B patent, one or two solvents in 175g isopropanol, benzene, toluene, xylene, cyclohexane, tetrahydrofuran, add Put it into a 0.5L high-pressure reactor, first remove the air in the reactor, replace it with hydrogen repeatedly several times, stir and heat to 60°C, and fill it with hydrogen to 4MPa to react for 5 hours. After the reaction, filter, wash, and evaporate the solvent. The sample was analyzed by 1H NMR spectrum, and the hydrogenation rate of HNBR was 97.8%.

Embodiment 2

[0046]Accurately weigh 25 g NBR, 2.5 g 3wt% Pd / C catalyst prepared by CN 101966455 B patent, one or two solvents in 175 g isopropanol, benzene, toluene, xylene, cyclohexane, tetrahydrofuran, add Put it into a 0.5L high-pressure reactor, first remove the air in the reactor, replace it with hydrogen repeatedly several times, stir and heat to 60°C, and fill it with hydrogen to 4MPa to react for 6 hours. After the reaction, filter, wash, and evaporate the solvent. The sample was analyzed by 1H NMR spectrum, and the hydrogenation rate of HNBR was 98.5%.

Embodiment 3

[0048] Accurately weigh 25 g NBR, 2.5 g 3wt% Pd / C catalyst prepared by CN 101966455 B patent, one or two solvents in 175 g isopropanol, benzene, toluene, xylene, cyclohexane, tetrahydrofuran, add Put it into a 0.5L high-pressure reactor, first remove the air in the reactor, replace it with hydrogen repeatedly several times, stir and heat it to 70°C, and fill it with hydrogen to 4MPa for 5 hours. After the reaction, filter, wash, and evaporate the solvent. The sample was analyzed by 1H NMR spectrum, and the hydrogenation rate of HNBR was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com