Water-like air-purifying oily polyurethane finishing paint and preparation method thereof

An oil-based polyurethane, deodorizing technology, applied in the field of coatings, can solve the problems of dizziness, inability to fully release, discomfort, etc., achieve the effect of good transparency, ensure drying speed and film permeability, and wide application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

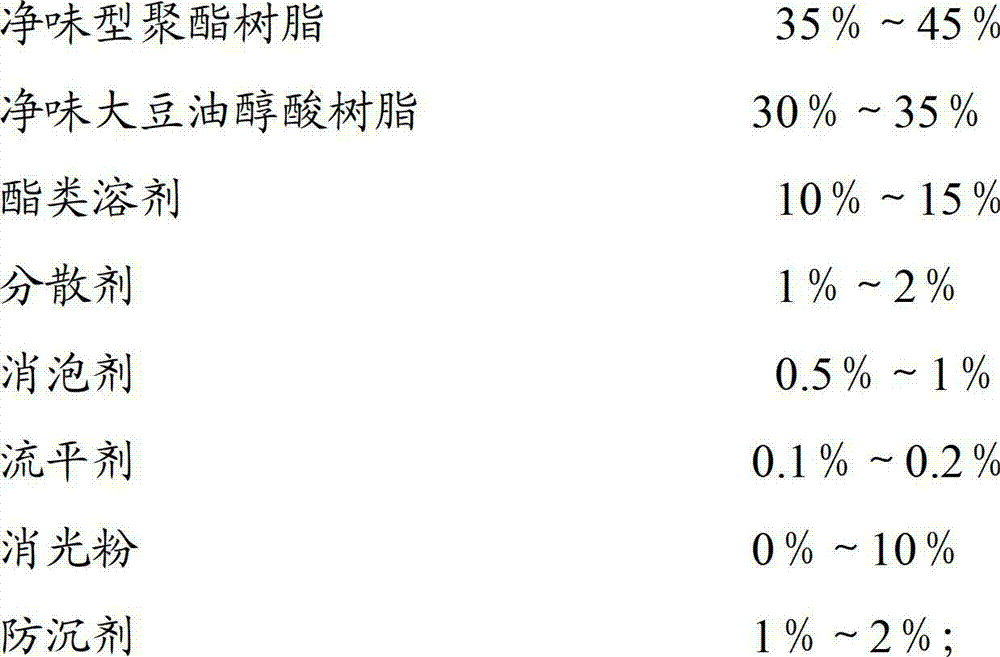

Method used

Image

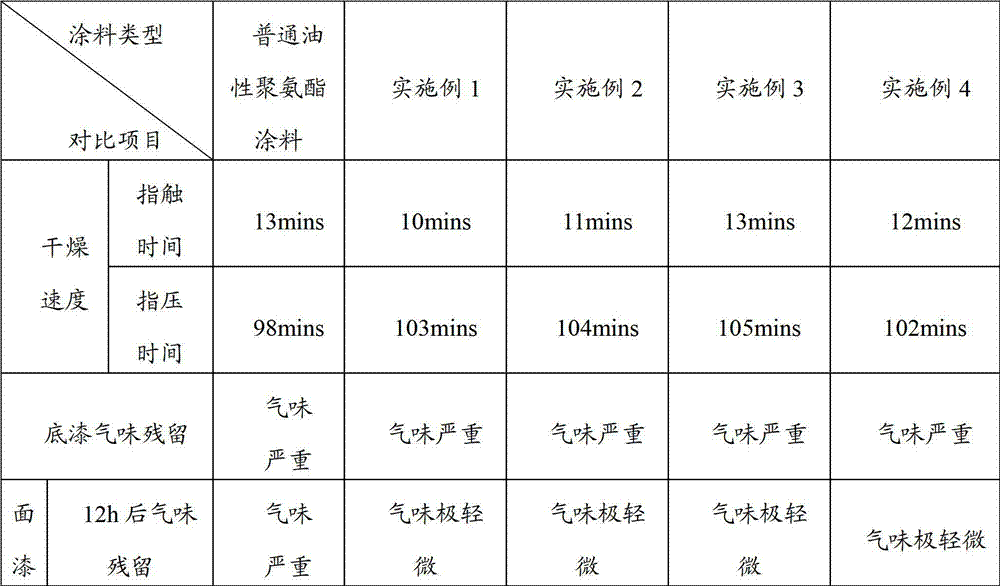

Examples

Embodiment 1

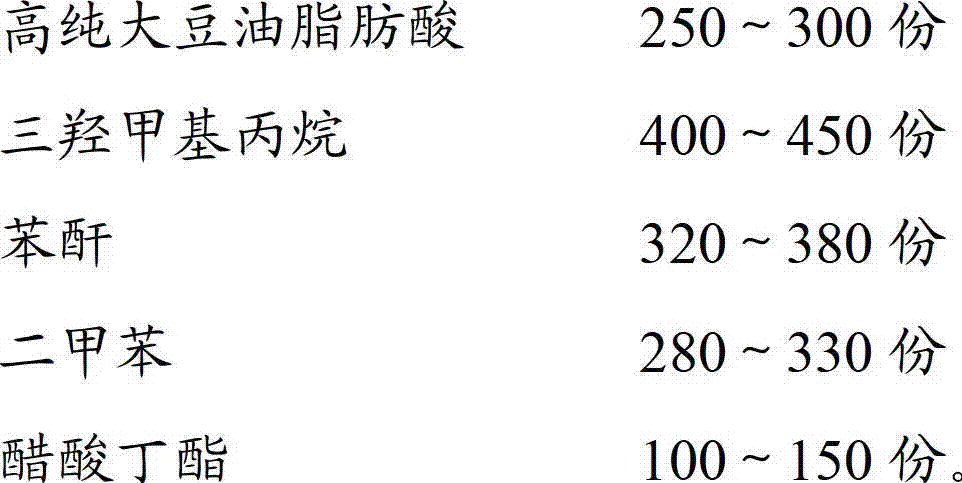

[0045] A kind of pure flavor soybean oil alkyd resin, is made up of the following materials calculated by weight:

[0046] 250 parts of high-purity soybean oil fatty acid, 450 parts of trimethylolpropane, 320 parts of phthalic anhydride, 330 parts of xylene and 148 parts of butyl acetate.

[0047] The method for preparing the net taste soybean oil alkyd resin is specifically prepared as follows:

[0048] First put the high-purity soybean oil fatty acid, trimethylolpropane, phthalic anhydride and 10% xylene into the reaction kettle, and feed nitrogen; then heat the materials in the reaction kettle to 170 ° C, and react for 1.5 hours; Then the temperature is raised to 200°C, and the temperature is kept until the acid value is ≤12 to obtain the reaction mixture; finally, the reaction mixture is lowered to normal temperature, and the remaining xylene and the amount of butyl acetate are added to the reaction mixture, and the preparation is uniform to obtain the of net-flavored soy...

Embodiment 2

[0065] A kind of pure flavor soybean oil alkyd resin, is made up of the following materials calculated by weight:

[0066] 300 parts of high-purity soybean oil fatty acid, 400 parts of trimethylolpropane, 380 parts of phthalic anhydride, 280 parts of xylene and 138 parts of butyl acetate.

[0067] The method for preparing the net taste soybean oil alkyd resin is specifically prepared as follows:

[0068] First put the amount of high-purity soybean oil fatty acid, trimethylolpropane, phthalic anhydride and 16% xylene into the reactor, and feed nitrogen; then heat the materials in the reactor to 190°C, and react for 0.8 hours; Then the temperature is raised to 250°C, and the temperature is kept until the acid value is ≤12 to obtain the reaction mixture; finally, the reaction mixture is lowered to normal temperature, and the remaining xylene and the amount of butyl acetate are added to the reaction mixture, and the preparation is uniform to obtain the of net-flavored soybean oil...

Embodiment 3

[0085] A kind of pure flavor soybean oil alkyd resin, is made up of the following materials calculated by weight:

[0086] 275 parts of high-purity soybean oil fatty acid, 433 parts of trimethylolpropane, 350 parts of phthalic anhydride, 300 parts of xylene and 140 parts of butyl acetate.

[0087] The method for preparing the net taste soybean oil alkyd resin is specifically prepared as follows:

[0088] First put the amount of high-purity soybean oil fatty acid, trimethylolpropane, phthalic anhydride and 14.3% xylene into the reactor, and feed nitrogen; then heat the materials in the reactor to 180°C and react for 1 hour; Then the temperature is raised to 220°C, and the temperature is kept until the acid value is ≤12 to obtain the reaction mixture; finally, the reaction mixture is lowered to normal temperature, and the remaining xylene and the amount of butyl acetate are added to the reaction mixture, and the preparation is uniform to obtain the of net-flavored soybean oil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com