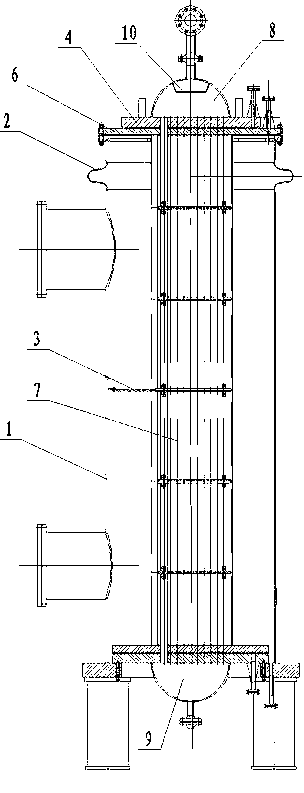

Novel efficient steam heater

A steam heater, high-efficiency technology, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc. Problems such as difficulty in manufacturing, to achieve the effect of easy control of manufacturing quality, easy assurance of manufacturing quality, and reduction of invalid lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

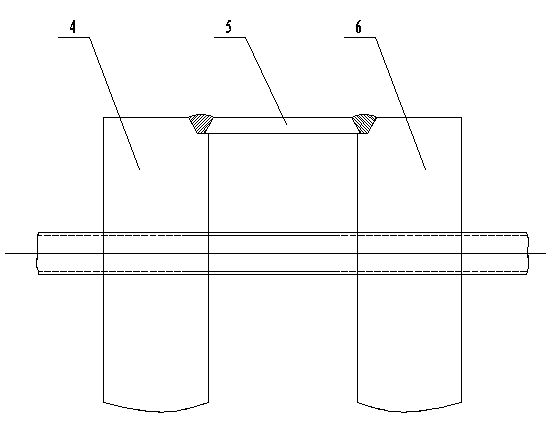

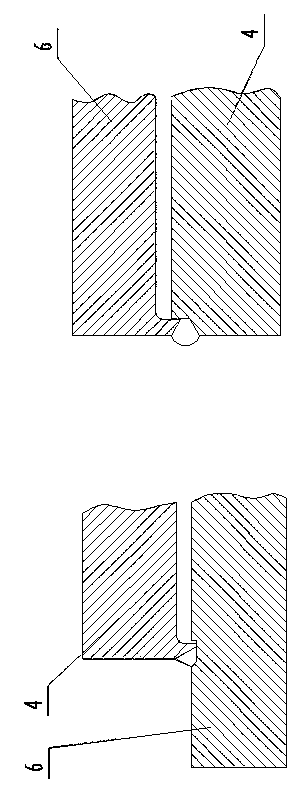

Method used

Image

Examples

Embodiment 1

[0025] For a set of steam heaters used in the purification system of the 40,000 air separation unit, if the traditional double tube plate structure is adopted, two heat exchangers with a shell diameter of DN1400mm and a total length of about 5.5m should be selected. The number of heat exchange tubes required for a single heat exchanger is 4001, with a total weight of about 31 tons. There are 4 tube sheets and multiple baffles in a double tube sheet heat exchanger, and 4,001 holes must be drilled on each tube sheet and baffle, which makes the parts processing and product assembly quite complicated and cumbersome. If the new high-efficiency steam heater of the present invention is selected, it is only necessary to select one heat exchanger with a shell diameter of DN1900mm and a total length of about 7.7m, the number of heat exchange tubes is about 250, and the total weight is about 21 Ton. After selecting the new high-efficiency steam heater of the present invention, under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com