Formation method for semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as increased cost, achieve the effects of reduced resistance, reduced process steps, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] As mentioned in the background, the conventional process for forming resistors in logic circuits or flash memory circuits is still relatively complicated, which is not conducive to reducing process costs.

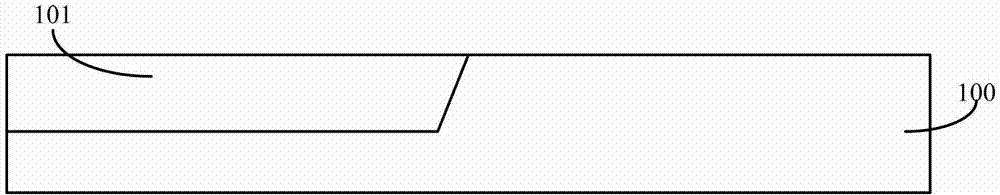

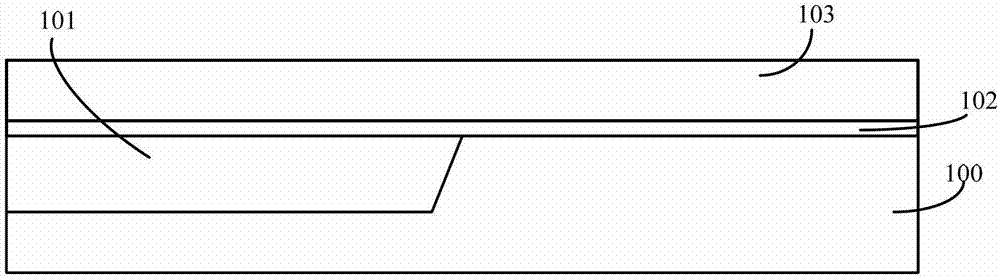

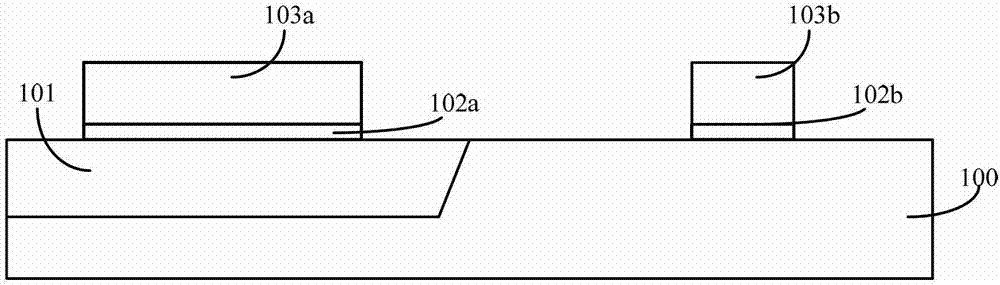

[0025] The inventor of the present invention has found through research, please continue to refer to Figure 1 to Figure 3 Since the polysilicon film 103 located on the surface of the semiconductor substrate 100 is subsequently used to form the gate electrode layer of the logic transistor, it is necessary to form a metal silicide layer on the surface of the polysilicon film 103 corresponding to the position where the gate electrode layer needs to be formed later, and the metal The silicide layer is used as an electrode of the gate electrode layer of the logic transistor to electrically connect other devices in the circuit or to apply a working voltage.

[0026] However, in order to prevent the formation of a metal silicide layer on the surface of the polysilicon film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com