Kitchen waste collecting and separating device

A kitchen waste and separation device technology, applied in the field of environmental protection, can solve problems such as bad smell, poor working environment, secondary pollution, etc., achieve high-efficiency screening and crushing effects, excellent adaptability and reliability, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

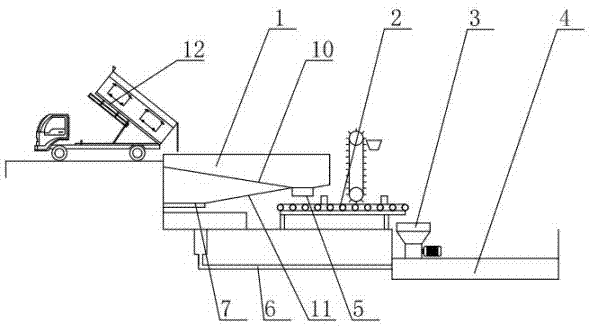

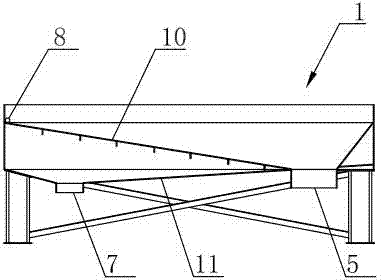

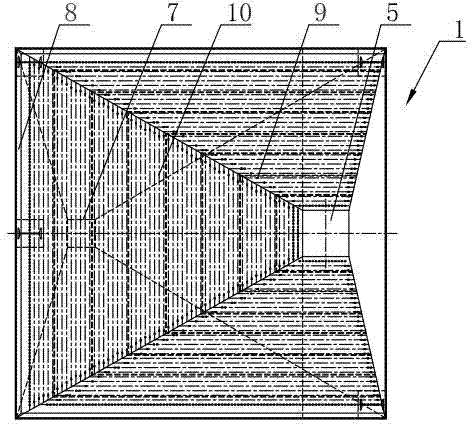

[0015] like figure 1 As shown, the present invention is a collection bucket 1 structure arranged at the front of the kitchen waste treatment line, such as figure 2 , image 3 As shown, the collection hopper 1 is a double-layer hopper structure, and the top layer is welded by a number of perforated filter plates 10 densely covered with filtrate holes 9 to form a conical hopper. A slag outlet 5 is formed at the bottom of the hopper, and a stainless steel wire screen is arranged at the slag outlet 5 , the conveyor belt of the screening device 2 is set below the slag outlet 5; the lower hopper bottom plate 11 is not provided with holes, and a liquid outlet 7 is formed at the bottom of the hopper, and the liquid outlet 7 is connected to the slag-liquid mixing tank 4 through the infusion pipe 6. Around the mouth of the top hopper, a hot water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com